Device and method for plasma-hypergravity coupling cooperative removal of gas pollutants

A technology for removing gas and plasma, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as uneven distribution of gas and solids, reduce mass transfer, etc., and achieve the effect of improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings.

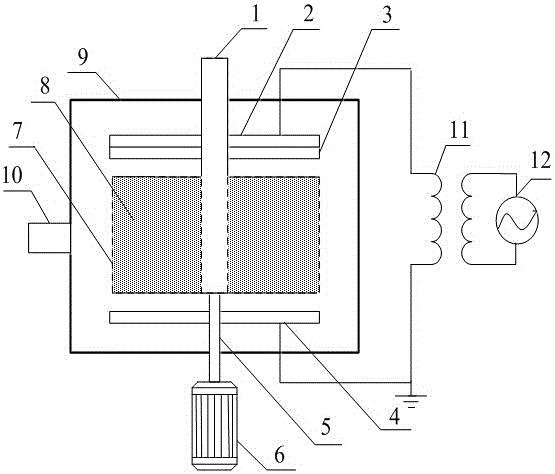

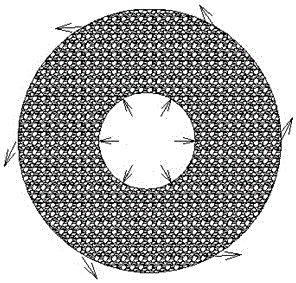

[0024] The plasma-high gravity coupling cooperative gas pollutant removal device of the present invention combines low-temperature plasma and high-gravity technology. It includes a flue gas pipeline 1, a high-voltage discharge electrode 2, a quartz dielectric layer 3, a non-metallic frame 7 and a ground electrode 4. The upper end of the flue gas pipeline 1 passes through the reactor shell 9, and its lower end is located in the non-metallic frame 7 with holes on the side. , the high-voltage discharge electrode 2, the quartz dielectric layer 3 and the non-metallic frame 7 are arranged in order from top to bottom around the flue gas pipe 1, the grounding electrode 4 is arranged directly under the non-metallic frame 7, and the non-metallic frame 7 is equipped with a solid adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com