Crystal silicon dioxide/carbon porous composite material and preparation method thereof

A technology of porous composite materials and amorphous silica, which is applied in the field of molten salt electrochemistry, can solve the problems affecting the electrolytic reaction rate and achieve the effect of small resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

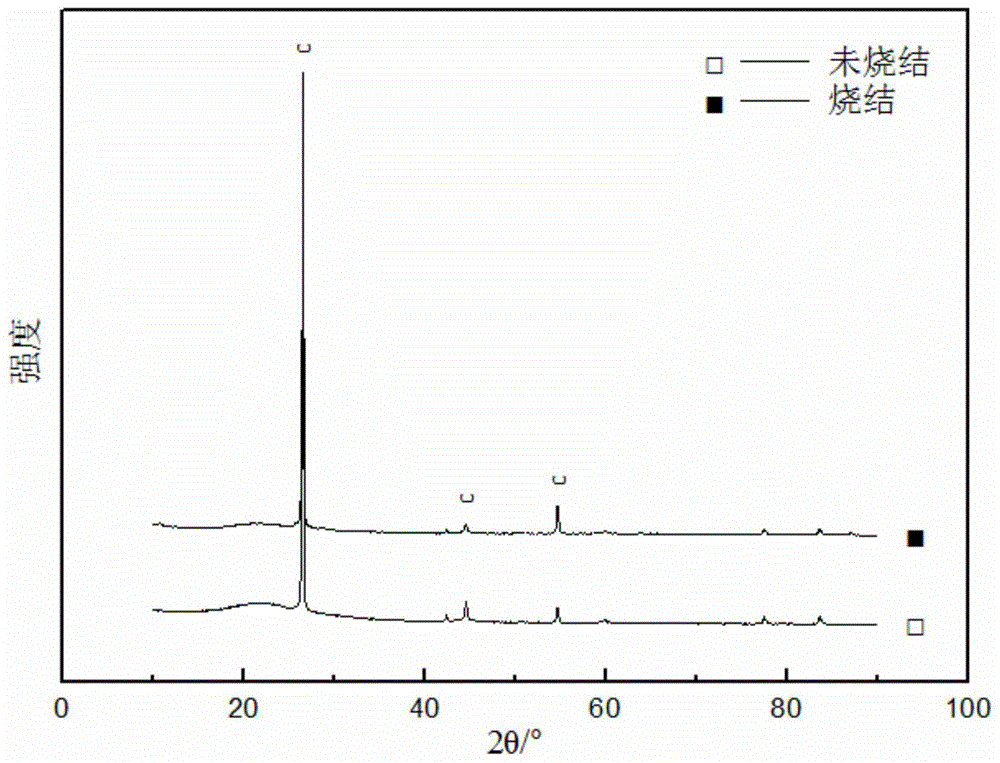

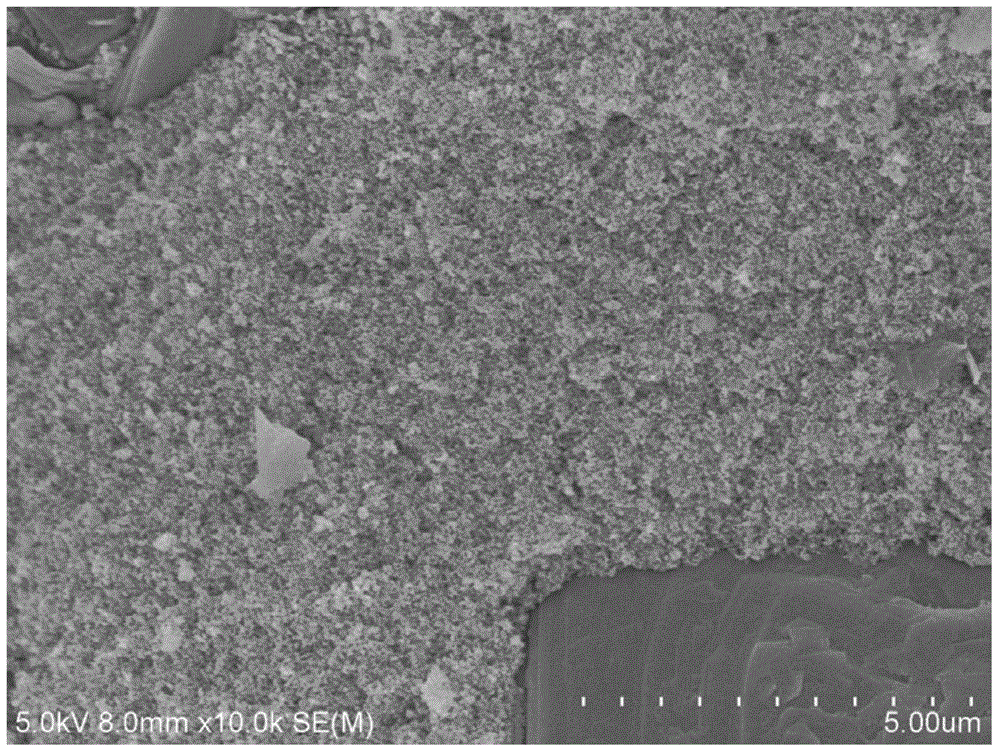

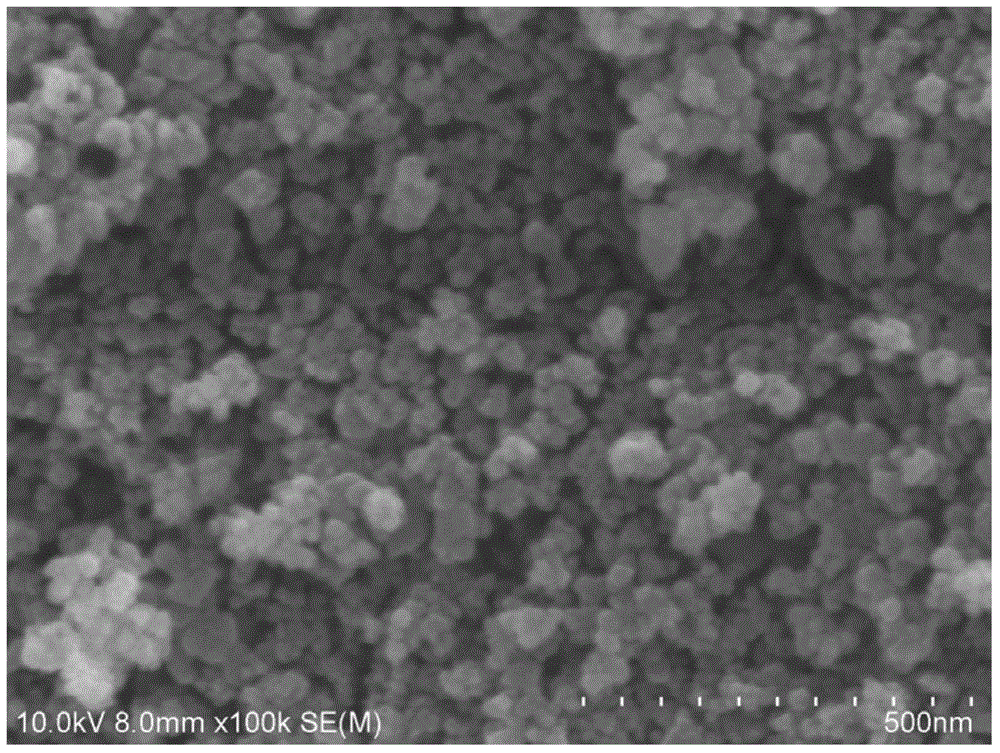

Embodiment 1

[0040] Mix the flux and dispersant with a mass ratio of 5% to form a uniform solution: the flux is NaCl, analytically pure; the dispersant is deionized water; it is carried out in a planetary mixer. Mix silicon dioxide with a mass ratio of 57% and the above solution to form a uniform silicon dioxide sol: the silicon dioxide is prepared by a gas phase method with a particle size of 30±5nm and a purity of ≥99.5% in a planetary mixer . The carbon with a mass ratio of 38% is uniformly mixed with the above-mentioned silica sol, and the carbon is lithium-ion battery negative electrode material 918, and the D90 is 28.0-34.0 μm; it is carried out in a planetary mixer. The mixed slurry was dried in an oven at 100° C. for 24 h, and crushed into powder. The mixed powder is pressed into a mold under uniaxial pressure. The compact is sintered under an inert protective atmosphere: the protective atmosphere is argon; the sintering temperature is 900° C.; the holding time is 3 hours, and th...

Embodiment 2

[0043] Mix the flux and dispersant with a mass ratio of 10% to form a uniform solution: the flux is NaCl, analytically pure; the dispersant is deionized water; it is carried out in a planetary mixer. Mix silicon dioxide with a mass ratio of 54% and the above solution to form a uniform silicon dioxide sol: the silicon dioxide is prepared by a gas phase method, with a particle size of 30±5nm and a purity of ≥99.5%, and is carried out in a planetary mixer . The carbon with a mass ratio of 36% is uniformly mixed with the above-mentioned silica sol, and the carbon is lithium-ion battery negative electrode material 918, and the D90 is 28.0-34.0 μm; it is carried out in a planetary mixer. The mixed slurry was dried in an oven at 100° C. for 24 h, and crushed into powder. The mixed powder is pressed into a mold under uniaxial pressure. The compact is sintered under an inert protective atmosphere: the protective atmosphere is argon; the sintering temperature is 900° C.; the holding t...

Embodiment 3

[0049] Mix the flux and dispersant with a mass ratio of 5% to form a homogeneous solution: the flux is CaCl 2 , analytically pure; the dispersant is deionized water; carried out in a planetary mixer. Mix silicon dioxide with a mass ratio of 57% and the above solution to form a uniform silicon dioxide sol: the silicon dioxide is prepared by a gas phase method, with a particle size of 30±5nm and a purity of ≥99.5%; carried out in a planetary mixer . The carbon with a mass ratio of 38% is uniformly mixed with the above-mentioned silica sol, and the carbon is lithium-ion battery negative electrode material 518, and the D90 is 26.0-32.0 μm; it is carried out in a planetary mixer. The mixed slurry was dried in an oven at 100° C. for 24 h, and crushed into powder. The mixed powder is pressed into a mold under uniaxial pressure. The compact is sintered under an inert protective atmosphere: the protective atmosphere is argon; the sintering temperature is 1200° C.; the holding time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median aperture | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Median aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com