Method for preparing high-efficiency phosphor powder

A fluorescent powder and high-efficiency technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of uneven particle size distribution, increase the scattering coefficient, and affect the luminous performance, so as to increase the reactivity, The effect of lowering the roasting temperature and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

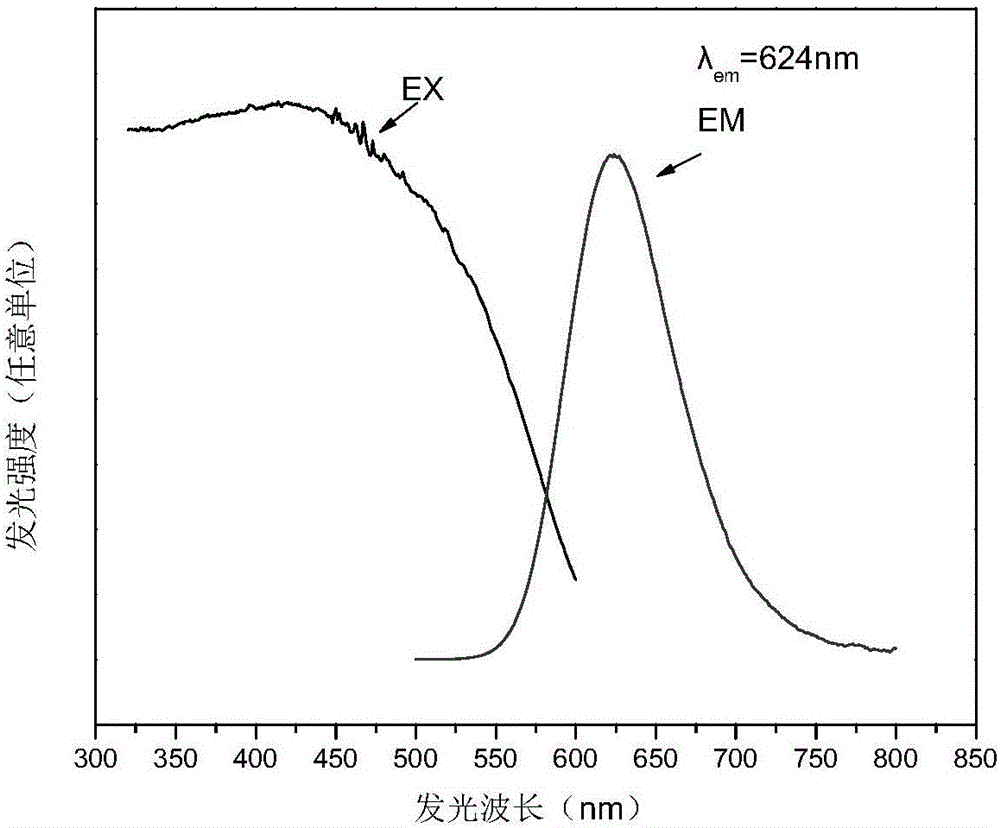

[0048] Example 1 (Ca 0.14 Sr 0.85 )(Al 0.5 Si 0.5 ) 2 N 3 : Eu 0.01

[0049] The raw material that synthesis embodiment 1 material adopts is Sr 3 N 2 , Ca 3 N 2 , Si 3 N 4 , AlN, Eu 2 o 3 . Weigh 100 g of the raw materials shown below and mix them.

[0050]

[0051] After weighing the above raw materials, put the powder in a mortar and mix evenly in a glove box (oxygen content<1ppm, water content<1ppm).

[0052] The mortar is onyx or alumina ceramic. Put the mixed powder into the crucible, compact it lightly, then take it out from the glove box and place it in a high-temperature graphite furnace. The material of the crucible is molybdenum or boron nitride. After the graphite furnace is evacuated and filled with nitrogen, it starts to heat up at a rate of 10°C / min, and the pressure of nitrogen is 1 atmosphere. Heat up to 1800°C and keep warm for 6 hours. After the keep warm, turn off the power and cool down with the furnace. The burnt samples were taken o...

Embodiment 8

[0055] Example 8 (Ca 0.14 Sr 0.85 )(Al 0.5 Si 0.5 ) 2 N 3 : Eu 0.01

[0056] The raw material that synthesis embodiment 1 material adopts is Sr 3 N 2 , Ca 3 N 2 , Si 3 N 4 , AlN, Eu 2 o 3 , Weigh 100 g of the raw materials shown below and mix them. And using 5.0wt% porous aluminum fluoride (AlF 3 ) as a flux.

[0057]

[0058] After weighing the above raw materials, put the powder in a mortar and mix evenly in a glove box (oxygen content<1ppm, water content<1ppm).

[0059] The mortar is onyx or alumina ceramic. Put the mixed powder into the crucible, compact it lightly, then take it out from the glove box and place it in a high-temperature graphite furnace. The material of the crucible is molybdenum or boron nitride. After the graphite furnace is evacuated and filled with nitrogen, it starts to heat up at a rate of 10°C / min, and the pressure of nitrogen is 1 atmosphere. Heat up to 1750°C and keep warm for 6 hours. After the keep warm, turn off the power ...

Embodiment 13

[0062] Example 13 (Ca 0.40 Sr 0.59 )(Al 0.5 Si 0.5 ) 2 (N 0.9 f 0.1 ) 3 : Eu 0.01

[0063] The raw material that synthetic embodiment 13 materials adopt is Sr 3 N 2 , Ca 3 N 2 , Si 3 N 4 , AlN, EuN, weigh 100g of the raw materials shown below and mix them. And use 1.0wt% porous sodium fluoride (NaF) as a flux.

[0064]

[0065] After weighing the above raw materials, put the powder in a mortar and mix evenly in a glove box (oxygen content<1ppm, water content<1ppm).

[0066] The mortar is onyx or alumina ceramic. Put the mixed powder into the crucible, compact it lightly, then take it out from the glove box and place it in a high-temperature graphite furnace. The material of the crucible is molybdenum or boron nitride. After the graphite furnace is evacuated and filled with nitrogen, it starts to heat up at a rate of 10°C / min, and the pressure of nitrogen is 1 atmosphere. Heat up to 1750°C and keep warm for 6 hours. After the keep warm, turn off the power ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com