Aqueous binder for vulcanized shoe and preparation method of aqueous binder

A water-based adhesive and adhesive technology, applied in the direction of adhesive types, natural rubber adhesives, polyurea/polyurethane adhesives, etc. Safety hazards and other issues, to achieve the effect of improving adhesion and water resistance, benefiting health protection, and improving cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

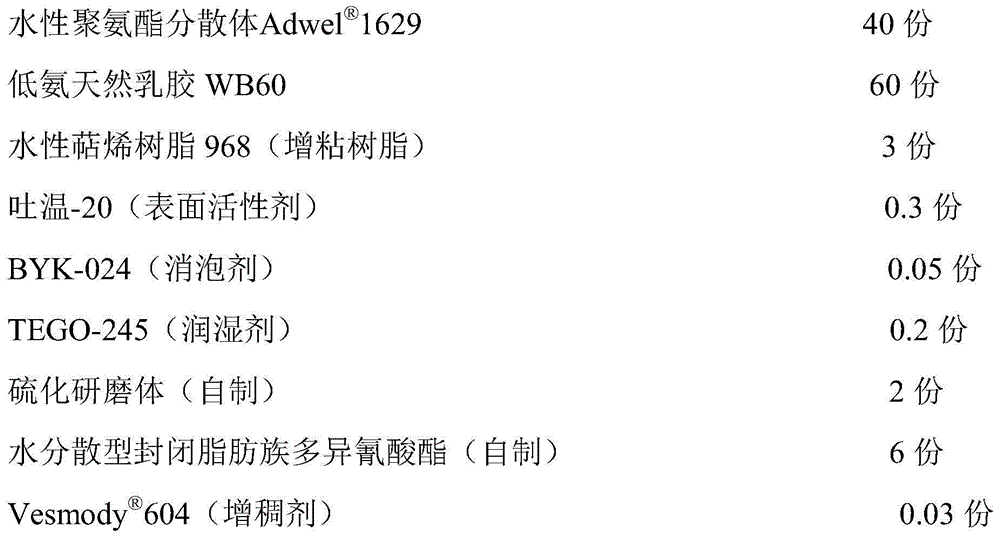

Embodiment 1

[0038] The raw materials used in embodiment 1 are as follows, aqueous polyurethane dispersion 1629: solid content of 50±1wt.%, molecular weight of 150,000 Daltons, Wanhua Chemical Group Co., Ltd.; low ammonia natural latex WB60, solid content of 60±1wt.%, ammonia addition of 0.25wt.% . : Guangzhou Zhifeng Trading Co., Ltd.; water-based terpene resin 968: Shenzhen Yoshida Chemical Co., Ltd.; Tween-20: Guangzhou Runhua Food Additives Co., Ltd.; defoamer BYK-022, BYK-024: Qingdao Hualing Chemical Products Co., Ltd.; wetting agent TEGO-245: Nanjing Hanbao Industrial Raw Materials Co., Ltd.; thickener 604: Wanhua Chemical Group Co., Ltd.; Water-dispersible aliphatic polyisocyanate 161 (polyethylene glycol modified HDI trimer): solid content of 100wt.%, NCO content of 18.5wt.%, Wanhua Chemical Group Co., Ltd.; dispersant DISPERBYK-2012: Qingdao Hualing Chemical Products Co., Ltd. Company; rheology modifier BYK-425: Qingdao Hualing Chemical Products Co., Ltd.; vulcanization acc...

Embodiment 2

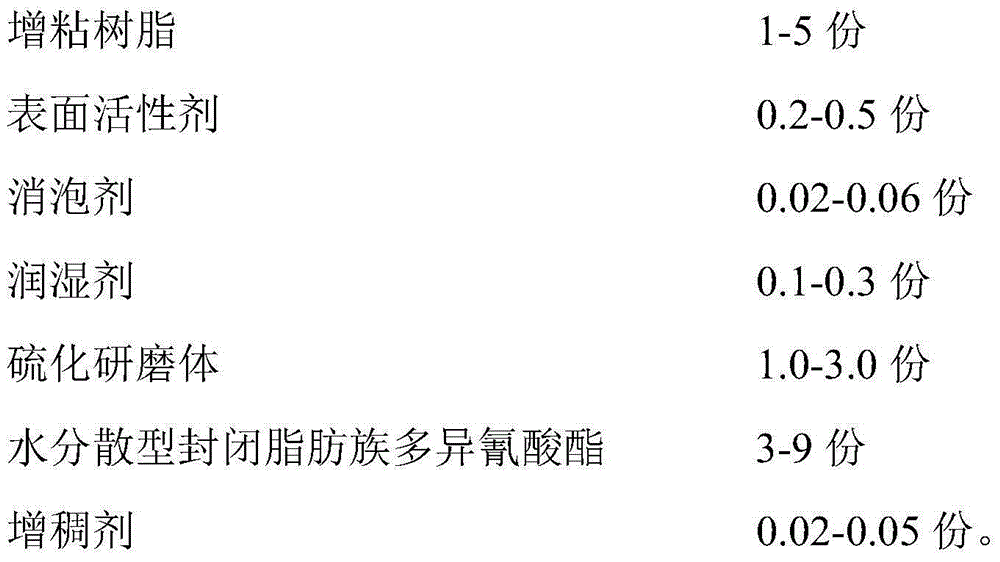

[0079] A water-based adhesive for vulcanized shoes is composed of the following two components. Wherein, the binder component is made up of the following components by weight:

[0080]

[0081]

[0082] Curing agent component is made up of the component of following parts by weight:

[0083] Water-dispersible aliphatic polyisocyanate 268 60 copies

[0084] Aziridine SC100 20 parts

[0085] 20 parts of ethyl acetate (cosolvent)

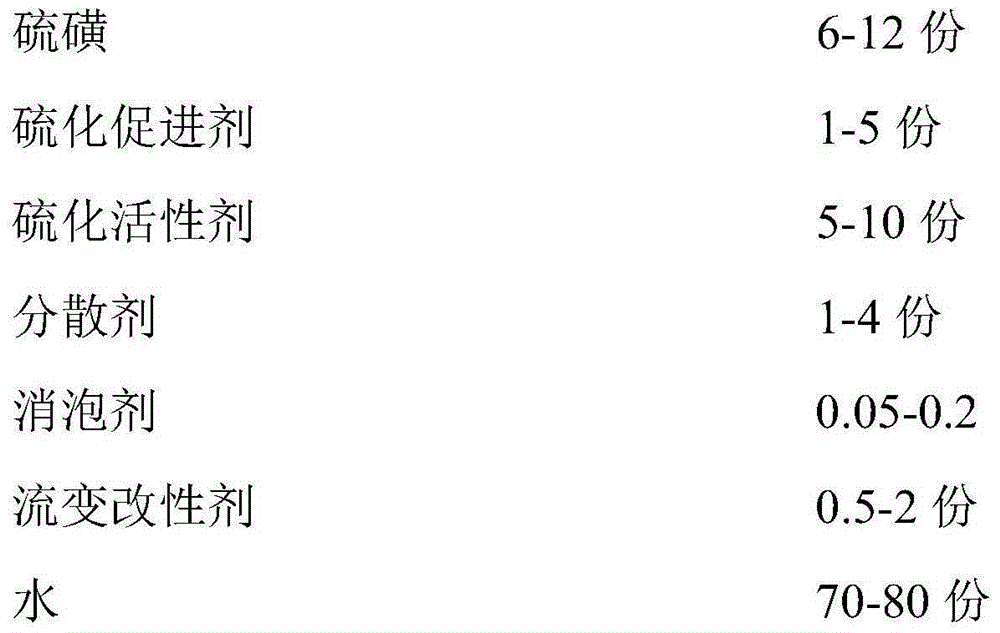

[0086] The vulcanized grinding body in the binder component is made up of the following components by weight:

[0087]

[0088] In this instance 268 (sulfonate-modified HDI trimer): the solid content is 100wt.%, the NCO content is 20.5wt.%, Wanhua Chemical Group Co., Ltd., and the suppliers of other raw materials are the same as in Example 1.

[0089] The preparation steps of the water-based adhesive for vulcanized shoes of this example are the same as Example 1. The physical and chemical indexes of the prepared adhesive component are...

Embodiment 3

[0107] A water-based adhesive for vulcanized shoes is composed of the following two components. Wherein, the binder component is made up of the following components by weight:

[0108]

[0109] Curing agent component is made up of the component of following parts by weight:

[0110] Water-dispersible aliphatic polyisocyanate 161 40 copies

[0111] Aziridine XC-103 40 parts

[0112] Acetone (solvent) 20 parts

[0113] The vulcanized grinding body in the binder component is made up of the following components by weight:

[0114]

[0115] In this example, the aqueous polyurethane dispersion 1630A: solid content of 50±1wt.%, molecular weight of 150,000 Daltons, Wanhua Chemical Group Co., Ltd.; Wanhua Chemical Group Co., Ltd.; ammonia-free natural latex WB620: solid content of 60±1wt.%, The amount of ammonia added is 0.1wt.%, Guangzhou Zhifeng Trading Co., Ltd.; Tween-80: Guangzhou Runhua Food Additives Co., Ltd.; defoamer BYK-020, BYK-028: Qingdao Hualing Chemical Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com