A kind of UV-transparent, high damage threshold fluorophosphate laser glass and its preparation method

A high damage threshold, fluorophosphate technology, applied in glass manufacturing equipment, glass furnace equipment, glass production and other directions, can solve the problems of easy crystallization of fluoride glass, difficult to produce large size, low triple frequency damage threshold, etc. Achieve the effect of stable chemical properties and suitable for large-scale mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

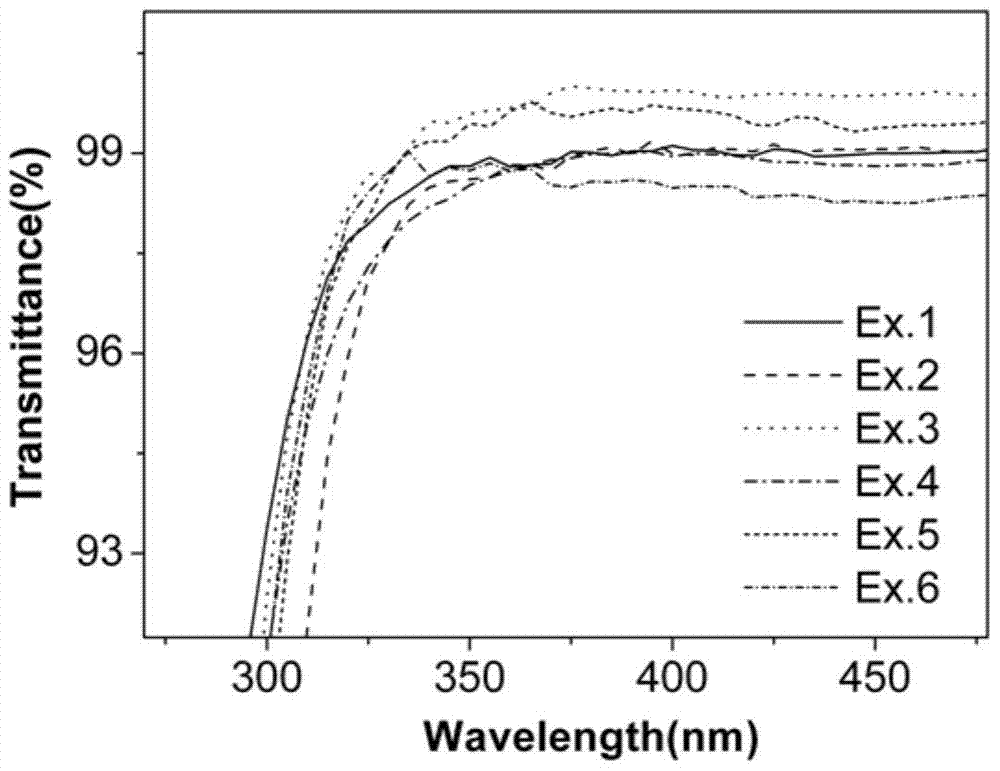

Embodiment 1

[0039] According to the above recipe 1 # Calculate the weight percent of the glass from the molar composition in the glass, then weigh a total of 25Kg of raw materials, and mix them uniformly in the mixing box. Add the prepared powder into the 11-liter platinum crucible in turn, and heat and melt it through a silicon carbide electric furnace. The melting temperature is controlled at about 1280 ° C, and the melting time is 6 hours. The liquid is stirred. After the glass liquid has been clarified to remove air bubbles and fully stirred evenly, the high-temperature glass liquid is injected into the copper mold preheated to 300°C through the leak nozzle at the bottom of the crucible to form a glass blank, and the formed glass sample is quickly demolded and placed in the Has been heated to the annealing temperature (set at the transition temperature T of the glass g In the muffle furnace nearby), after 12 hours of heat preservation, the temperature is lowered to 100°C at a coolin...

Embodiment 2

[0044] According to the above recipe 2 # Calculate the weight percent of the glass from the molar composition in the glass, then weigh a total of 25Kg of raw materials, and mix them uniformly in the mixing box. Add the prepared powder into the 11-liter platinum crucible in turn, and heat and melt it through a silicon carbide electric furnace. The melting temperature is controlled at about 1280 ° C, and the melting time is 6 hours. The liquid is stirred. After the glass liquid has been clarified to remove air bubbles and fully stirred evenly, the high-temperature glass liquid is injected into the copper mold preheated to 300°C through the leak nozzle at the bottom of the crucible to form a glass blank, and the formed glass sample is quickly demolded and placed in the Has been heated to the annealing temperature (set at the transition temperature T of the glass g In the muffle furnace nearby), after 12 hours of heat preservation, the temperature is lowered to 100°C at a coolin...

Embodiment 3

[0048] According to the above recipe 3 # Calculate the weight percent of the glass from the molar composition in the glass, then weigh a total of 25Kg of raw materials, and mix them uniformly in the mixing box. Add the prepared powder into the 11-liter platinum crucible in turn, and heat and melt it through a silicon carbide electric furnace. The melting temperature is controlled at about 1280 ° C, and the melting time is 6 hours. The liquid is stirred. After the glass liquid has been clarified to remove air bubbles and fully stirred evenly, the high-temperature glass liquid is injected into the copper mold preheated to 300°C through the leak nozzle at the bottom of the crucible to form a glass blank, and the formed glass sample is quickly demolded and placed in the Has been heated to the annealing temperature (set at the transition temperature T of the glass g In the muffle furnace nearby), after 12 hours of heat preservation, the temperature is lowered to 100°C at a coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com