Liquid-core optical fiber of multiple salts

A liquid core fiber and salt technology, applied in the field of multi-salt liquid core fiber, can solve the problems of large transmission loss, limited liquid core fiber, small fiber numerical aperture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1:Φ5、Φ6,。8~12,:CaCl2 70%,CaBr2 22%,KCL2 4%,NaH2PO4 4%。。:0.62,365nm82%。 Embodiment 2

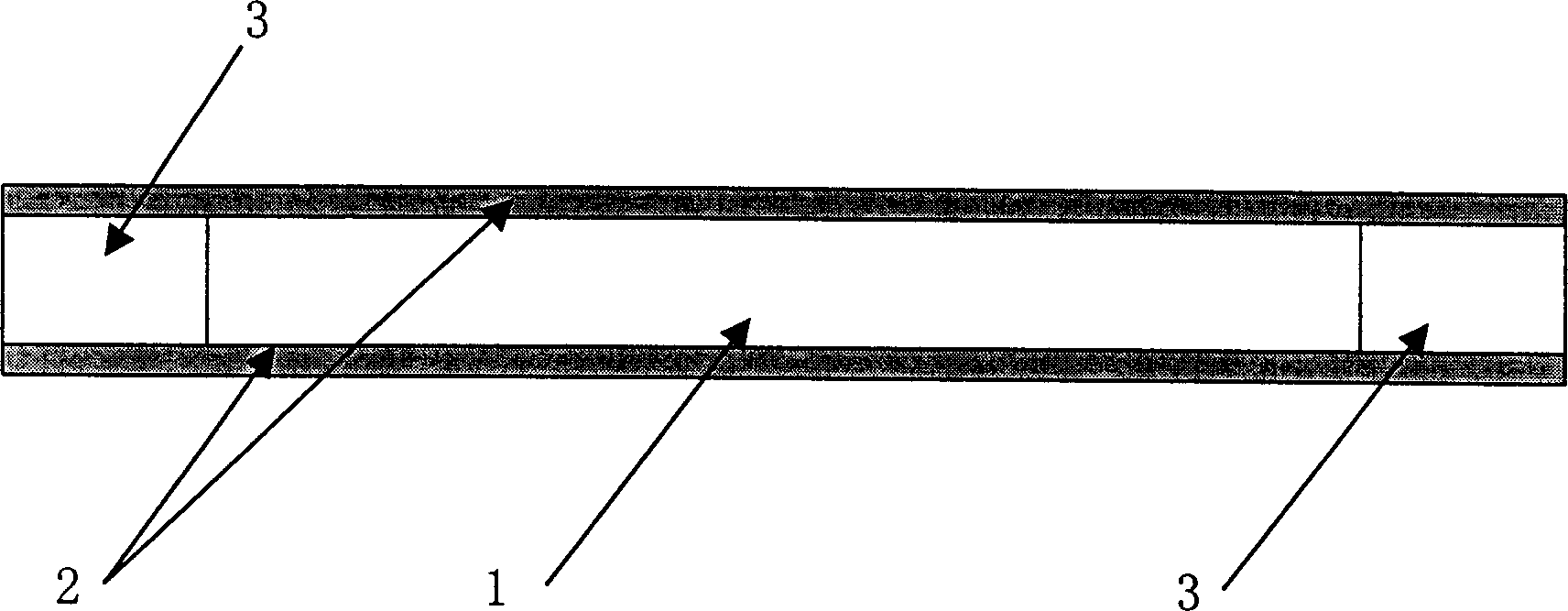

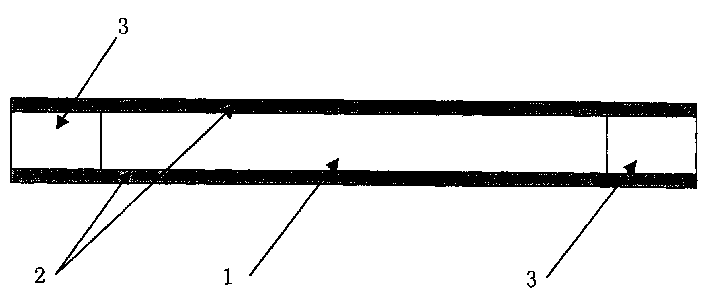

[0005] Such as figure 1 , the present invention is made by filling the clad hose 2 with multiple salt liquids 1 to form a flexible light guide, and the two ends are sealed with transparent light windows. The multi-salt liquid is composed of multiple aqueous phase addition solutions co-crystallized for 2-15 times. Solutions include: KCL 2 , CaBr 2 , CaCl 2 , NaH 2 PO 4 Wait. It has non-wetting plastic material and has good water absorption. The cladding hose can be composed of fluorine-containing and carbon-containing polymers, and the transparent light window can be a high-transmission quartz glass rod. Embodiment 1: Teflon tubes with an inner diameter of Φ5 and an outer diameter of Φ6 are used for the cortex, and the core material is poured into it. Among them, the core material is co-crystallized 8 to 12 times with multiple salt mixed aqueous solutions, and the contained components: CaCl 2 70%, CaBr 2 22%, KCL 2 4%, NaH 2 PO 4 4%. Both ends are sealed with h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com