Method for extracting flavonoid plant preservative from bamboos, products prepared through same and application of flavonoid plant preservative

A technology for plant preservatives and flavonoids, which is applied in the field of extraction of natural products from plants, can solve the problems of oxidation structure of active ingredients, reduce the effective storage time of extracts, low extraction efficiency, etc., and achieve good bacteriostatic and antiseptic performance, retention Antioxidant activity, effect of reducing solvent polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

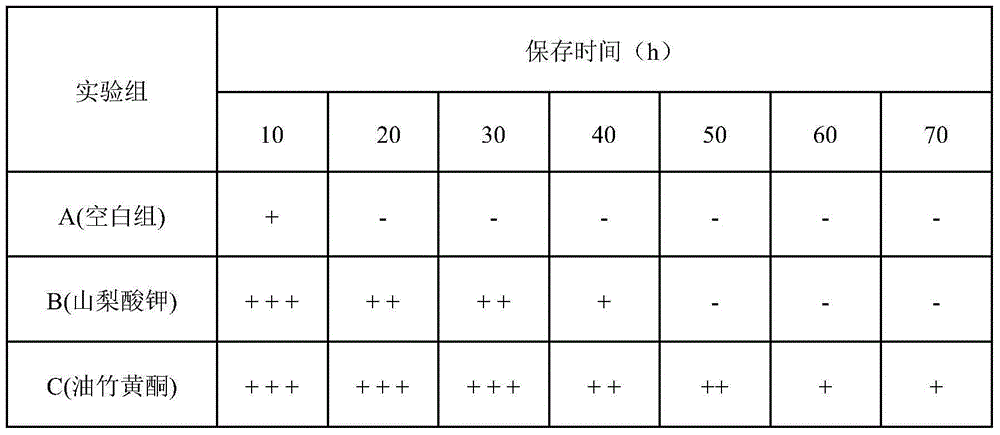

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] 1) Bamboo stems are obtained from oleifera oleifera in Enshi Prefecture, and the upper, middle and lower parts of the bamboo stems are respectively chopped and chopped, mixed and crushed mechanically to obtain 50 g.

[0035] 2) The boiling range of petroleum ether used is 60-90°C, the mass volume ratio (g / mL) of bamboo dry debris to petroleum ether volume is 1:20, and the number of petroleum ether degreasing and depigmentation times is 3 times.

[0036] 3) The dried bamboo scraps after degreasing are leached in a compound solvent of ethanol, acetic acid, ethyl acetate and water to obtain a preliminary flavonoid extract, the volume ratio of ethanol, acetic acid, ethyl acetate and water in the mixed solvent The ratio of solid to liquid is 50:5:10:35, the ratio of solid to liquid is 1:20, the extraction temperature is 80°C, and the extraction time is 1h.

[0037] 4) The flavonoid leachate is separated with a centrifuge for solid-liquid separation, concentrated under reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com