Method for constructing solution processing light emitting diode based on Cu-doped multi-element quantum dots

A technology of quantum dot solution and light-emitting diodes, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc. It can solve the problems of poor uniformity of phosphor particles, impact on service life, lack of red light, etc., and meet the requirements of operating equipment Low cost, easy operation, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Preparation of Se precursor solution

[0046] Take by weighing selenium powder simple substance 1mmol (selenium powder simple substance consumption can also be 2,3,4,5,6,7,8,9,10,11,12,2.9,3.3,4.1,5.3,6.2,7.3,8.7, 9.4, 10.6, 11.5, 1.2 and other arbitrary values within the range of 1-12mmol) were dissolved in the mixed solution of 10ml of octadecene ODE and organic amine ligand (oleylamine (OLA)) (wherein the volume ratio of ODE and OLA is 1:1) to form a homogeneous mixed solution.

[0047] The volume ratio of ODE to OLA in the mixed solution of octadecenyl ODE and organic amine ligand (oleylamine (OLA)) can also be 1:2, 1:3, 1:4, 1:5, 1:1.2, 1 :3.5, 1:2.1.

[0048] Preparation of Zn precursor solution

[0049] Take by weighing zinc salt (zinc acetate, zinc salt can also be one or more mixtures in zinc chloride, zinc stearate, diethyldithiocarbamate zinc) 1mmol (zinc salt consumption can also be 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 2.9, 3.3, 4.1, 5.3, 6.2, 7.3, 8.7,...

Embodiment 1

[0053] Preparation of quantum dots

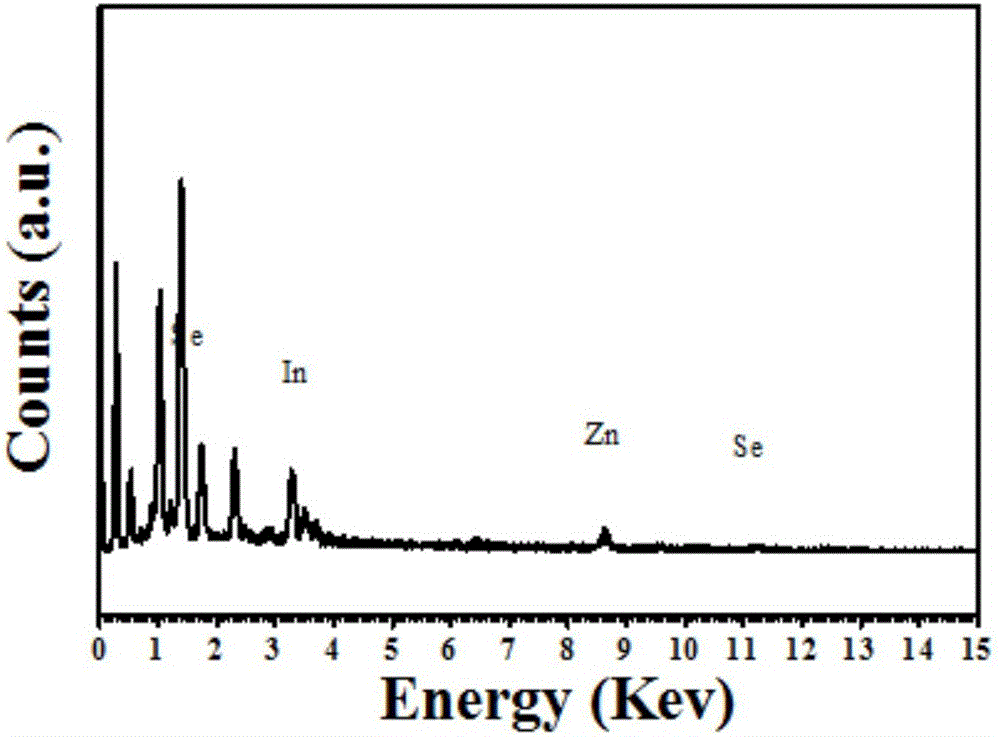

[0054] Weigh CuCl (4mg, 0.04mmol, copper salt can also be one or more mixtures of copper chloride, copper acetate, cuprous iodide), In(Ac) 3 (58mg 0.2mmol, the indium salt can also be one or a mixture of indium chloride and indium nitrate), Zn(Ac) 2 (36mg 0.2mmol, the zinc salt can also be one or a mixture of zinc chloride, zinc nitrate, zinc stearate) DDT (1mL), OLA (1mL) and ODE (5mL) were added to a 100mL three-neck in the bottle. The high-purity argon atmosphere in the bottle is ensured by repeated vacuuming and recirculation of argon. Raise the temperature from room temperature to 100°C for 20 minutes to remove residual water molecules and low-boiling organic matter, and obtain a transparent solution. Then the temperature was raised to 220°C and kept for 10 minutes. The selenium (Se) precursor solution (including 63mg (0.8mmol) Se, 1mL ODE and 1mL oleylamine (OLA)) was quickly injected into the three-necked bottle, and kept growing...

Embodiment 2

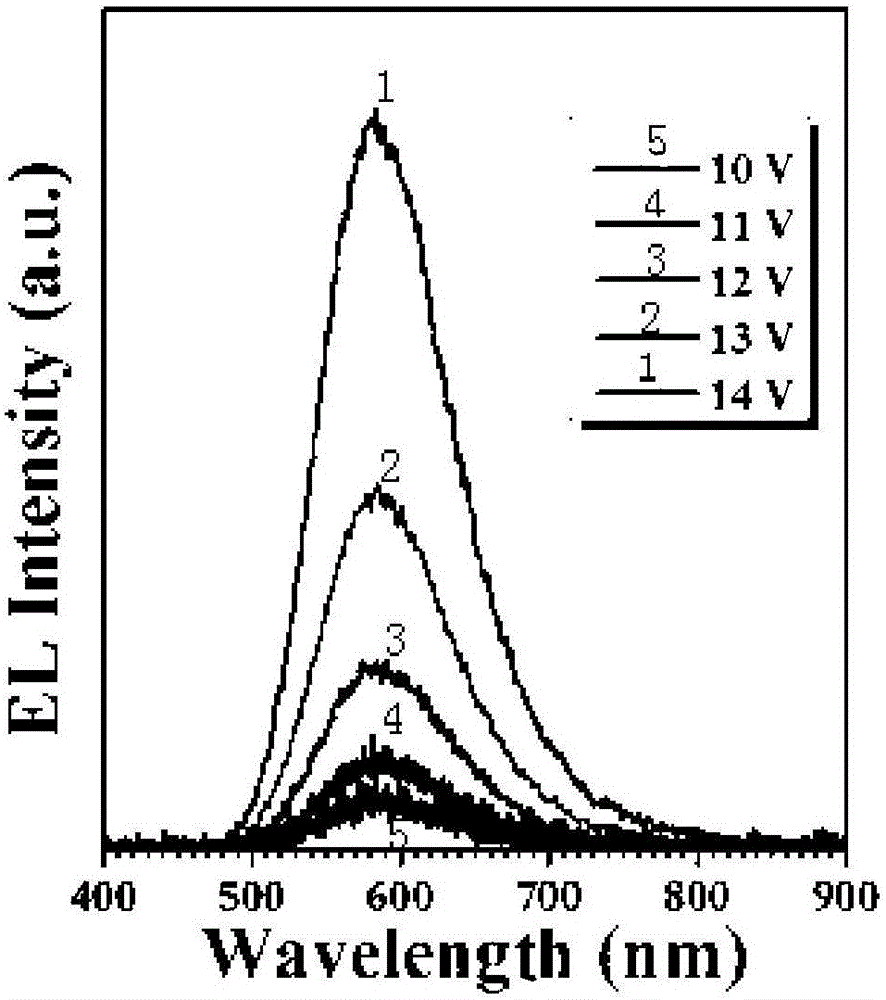

[0059] The assembly of the QD-LED in this embodiment is based on the substrate 2 provided with the ITO sheet 1 (the sheet resistance of the ITO sheet is ~20V sq-1), and the substrate of the ITO sheet is successively washed with acetone, absolute ethanol and deionized water Ultrasonic treatment for 10 minutes each, and then use an ultraviolet lamp to generate ozone in the air for 3 minutes. The NiO nanoparticle layer 3 was spin-coated on the substrate, and then baked in air at 180 °C for 10 min. Then spin-coat the hole transport layer 4poly(N,N9-bis(4-butylphenyl)-N,N9-bis(phenyl)-benzidine)(poly-TPD), the light-emitting layer 5Cu-doped multi-component quantum dot layer and the electron transport layer in sequence. Layer 6 ZnO nanoparticle layer. Poly-TPD is a hole transport layer, which is spin-coated with Chlobenzene solution (2000rpm, 50s) with a concentration of 1.3wt%, and then baked at 100°C for 30min. The layer of Cu-doped multi-component quantum dots (12mg / ml, toluene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com