Resistance reducing agent for fracture and preparation method thereof

A drag reducing agent and fracturing technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low clay swelling inhibition, slow dissolution rate of drag reducing agent, and low storage stability, etc. High swelling inhibition, low formation damage, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

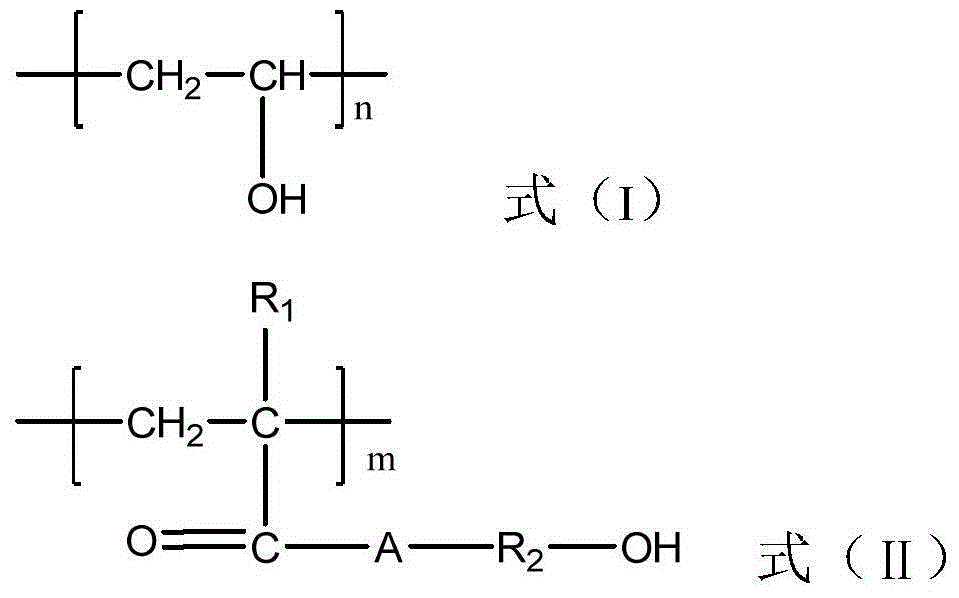

[0029] In one aspect, the present invention provides a method for preparing a drag reducing agent for fracturing, the method comprising:

[0030] (1) Mix acrylamide monomer, double bond-containing hydroxyl nonionic monomer, polyhydroxy nonionic polymer template, chelating agent, molecular weight regulator and water to obtain an aqueous solution;

[0031] (2) Contact the organic solvent with the emulsifier to obtain an oil solution;

[0032] (3) contacting the aqueous solution obtained in step (1) with the oil solution obtained in step (2) to obtain a water-in-oil emulsion;

[0033] (4) Under an inert atmosphere, contact the water-in-oil emulsion obtained in step (3) with an initiator in batches, and carry out a polymerization reaction, and then contact the mixture obtained by the polymerization reaction with a phase inversion agent;

[0034] Wherein, the hydrophilic-lipophilic balance value of the emulsifier is 4-6, the molecular weight of the polyhydroxy nonionic polymer tem...

Embodiment 1

[0071] This example is used to illustrate the drag reducing agent for fracturing of the present invention and its preparation method.

[0072] (1) At 15°C, mix 100g of acrylamide, 35g of 2-hydroxyethyl methacrylate, 2g of polyvinyl alcohol (type: 10-98, the molecular weight is 61,000), 0.1g disodium edetate, 0.05g sodium formate and 120g deionized water are mixed in a 1000mL beaker, stirred until completely dissolved to obtain an aqueous solution;

[0073] (2) Mix 10.5g Span-80 and 1.5g Tween-80 to obtain a mixed emulsifier, and calculate the hydrophilic-lipophilic balance value of the mixed emulsifier to be 5, then mix the mixed emulsifier with 120g white oil (boiling point distillation range 220-255°C, flash point 80°C) mixed in a 1500mL beaker until completely dissolved to obtain an oil solution;

[0074] (3) Add the aqueous solution obtained in step (1) to the oil solution obtained in step (2), and emulsify with a high-speed shear dispersing emulsifier for 1 min to obtai...

Embodiment 2

[0077] This example is used to illustrate the drag reducing agent for fracturing of the present invention and its preparation method.

[0078] (1) At 25°C, mix 100g of acrylamide, 30g of 2-hydroxyethyl methacrylate, and 5g of polyvinyl alcohol (type: 40-88, the molecular weight is 205,000), 0.2g disodium edetate, 0.1g sodium formate and 150g deionized water are mixed in a 1000mL beaker, stirred until completely dissolved to obtain an aqueous solution;

[0079] (2) Mix 10.5g Span-80 and 4.5g Tween-80 to obtain a mixed emulsifier, and calculate the hydrophilic-lipophilic balance value of the mixed emulsifier to be 6, then mix the mixed emulsifier with 150g white oil (boiling point distillation range 240-280°C, flash point 100°C) mixed in a 1500mL beaker until completely dissolved to obtain an oil solution;

[0080] (3) Add the aqueous solution obtained in step (1) to the oil solution obtained in step (2), and emulsify with a high-speed shear dispersing emulsifier for 1 min to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com