A kind of drag reducing agent for fracturing and preparation method thereof

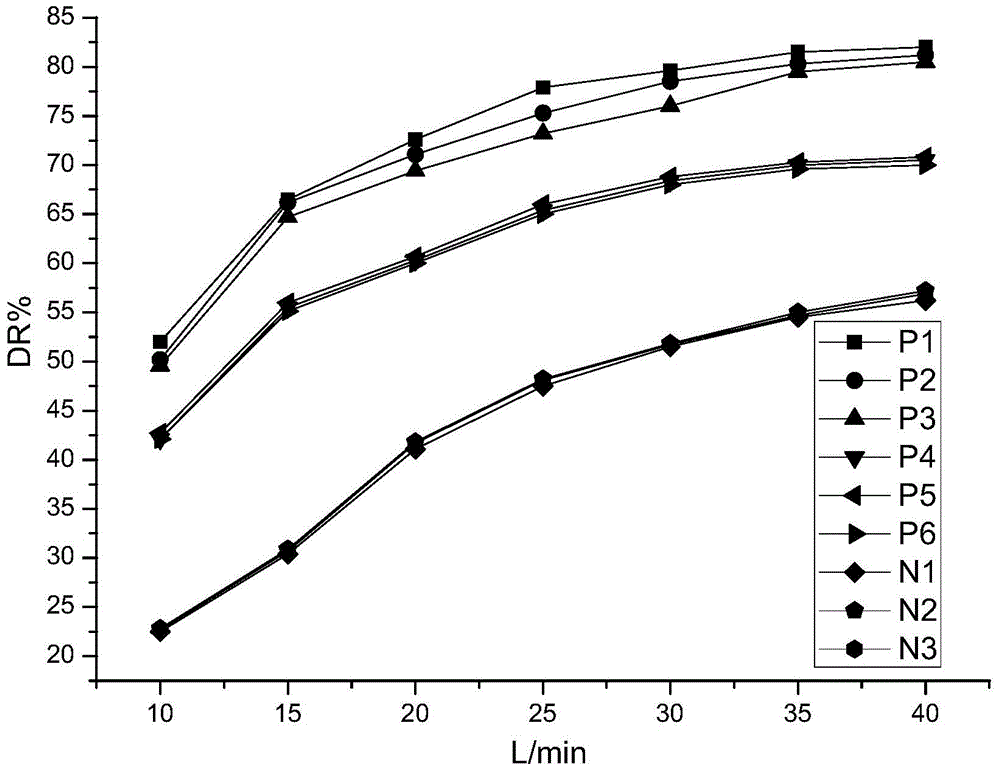

A drag-reducing agent and fracturing technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low clay expansion inhibition, low drag-reducing rate of drag-reducing agent, poor shear resistance, etc. To achieve the effects of clay expansion inhibition, improved drag reduction performance, non-combustible and explosive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In one aspect, the present invention provides a method for preparing a drag reducing agent for fracturing, the method comprising:

[0032] (1) mixing acrylamide-based monomers, double bond-containing anionic monomers, cationic polymer templates, dispersants, molecular weight regulators, inorganic salts and water and adjusting the pH value to obtain an aqueous solution with a pH value of 4-7;

[0033] (2) Under an inert atmosphere, the aqueous solution obtained in step (1) is contacted in batches with an initiator, and a polymerization reaction is carried out;

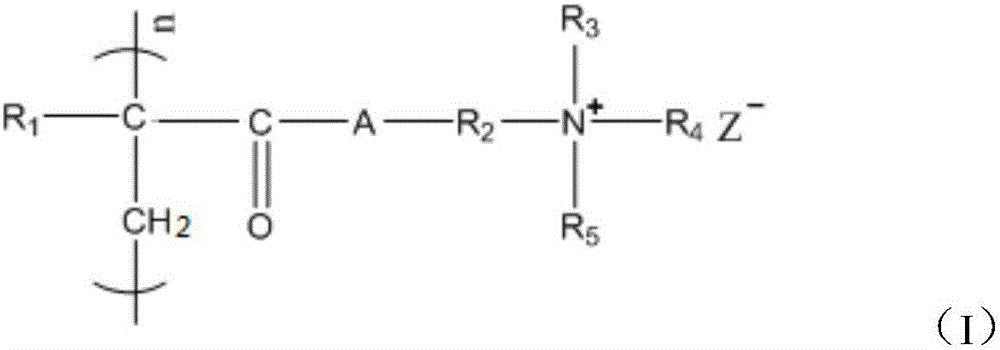

[0034] Wherein, the molecular weight of the cationic polymer template is less than 1 million, and the structural formula of the cationic polymer template is as shown in formula (I):

[0035]

[0036] R 1 is hydrogen or methyl;

[0037] A is O or NH;

[0038] R 2 is C 1 -C 6 the alkylene group;

[0039] R 3 , R 4 , R 5 is C 1 -C 6 the alkyl group;

[0040] Z is chlorine, bromine or iodine.

[0041...

Embodiment 1

[0065] This example is used to illustrate the drag reducing agent for fracturing of the present invention and its preparation method.

[0066] (1) At 15°C, add 523.3g of deionized water to a 1000mL polymerization reactor equipped with a condenser, thermometer, nitrogen inlet and agitator, then add 250g of ammonium sulfate to the polymerization reactor, and stir until completely dissolved Then, add 4.0g polymethacryloxyethyltrimethylammonium chloride (molecular weight: 200,000) to the polymerization reactor, stir until completely dissolved, then add 100g acrylamide, 30g sodium acrylate, After 8 g of sodium polyacrylate (molecular weight is 500,000), 0.5 g of sodium formate, stir until completely dissolved, and finally slowly add 1% by weight of NaOH aqueous solution to the solution obtained above, adjust the pH to 5, and obtain an aqueous solution with a pH of 5;

[0067] (2) under the condition of 16 DEG C, first add the ammonium persulfate aqueous solution of 10g 2% by weight...

Embodiment 2

[0069] This example is used to illustrate the drag reducing agent for fracturing of the present invention and its preparation method.

[0070] (1) At 20°C, add 536.9g of deionized water to a 1000mL polymerization reactor equipped with a condenser, thermometer, nitrogen inlet and agitator, then add 297g of ammonium sulfate to the polymerization reactor, and stir until completely dissolved , then add 5.0g polymethacryloxyethyltrimethylammonium chloride (molecular weight is 10,000) to the polymerization reactor, stir until completely dissolved, then add 100g acrylamide, 30g sodium acrylate, 5g 2 - After sodium acrylamido-2-methylpropanesulfonate and 0.1 g of sodium formate, stir until completely dissolved, and finally slowly add 1% by weight of NaOH aqueous solution to the solution obtained above, adjust the pH to 7, and obtain a solution with a pH of 7. aqueous solution;

[0071] (2) under the condition of 21 DEG C, first add the ammonium persulfate aqueous solution of 5g 2% by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com