Catalyst component used for ethylene polymerization reaction, catalyst and preparation method thereof

A technology of ethylene polymerization and catalyst, which is applied in the field of catalyst components, and can solve problems such as complex preparation methods, deposition, adhesion of carriers or catalyst particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

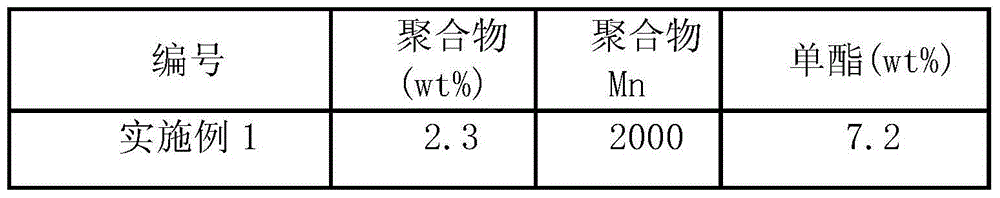

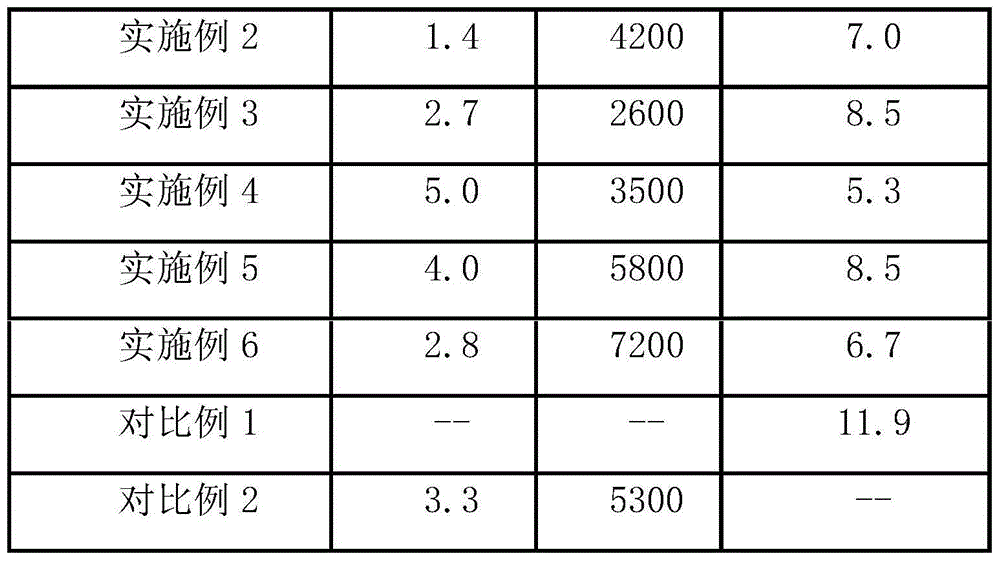

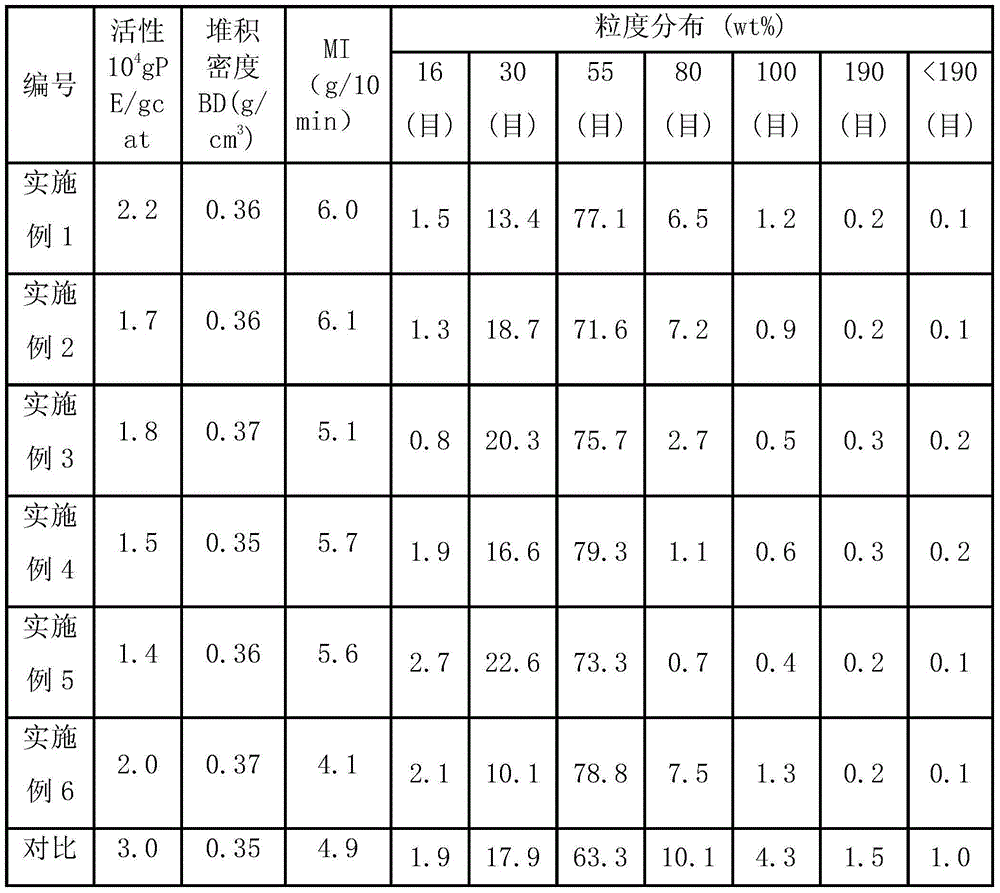

Examples

Embodiment 1

[0047] (1) Preparation of catalyst components

[0048] In the reactor fully replaced by high-purity nitrogen, add 6.0g spherical carrier MgCl in sequence 2 2.6C 2 h 5 OH, 120ml hexane, cooled down to -10°C with stirring, added dropwise 50ml triethylaluminum hexane solution (triethylaluminum: 1.2M) and 1ml n-octyl acetate, 0.5ml methyl acrylate, 5mg tert-butyl base hydroperoxide, then the temperature was raised to 60° C., and the reaction was maintained for 3 hours. Stirring was stopped and the mixture was left standing, the suspension was quickly separated into layers, the supernatant was sucked off, and the precipitate was washed twice with hexane at room temperature. Add 120ml of hexane, cool the system to 0°C, slowly add 8ml of titanium tetrachloride dropwise, then raise the temperature to 60°C, and react for 2 hours. Stop stirring, let it stand, the suspension will be layered quickly, and the supernatant will be pumped out. After the precipitate is washed twice with he...

Embodiment 2

[0054] (1) Preparation of catalyst components

[0055] In the reactor fully replaced by high-purity nitrogen, add 5.0g spherical carrier MgCl in sequence 2 3.0C 2 h 5 OH, 130ml hexane, cooled down to -5°C with stirring, added dropwise 45ml triethylaluminum hexane solution (triethylaluminum: 1.0M) and 1ml ethyl acetate, 0.5ml methyl methacrylate, 5mg over The di-tert-butyl group was oxidized, then the temperature was raised to 50° C., and the reaction was maintained for 2 hours. Stirring was stopped and the mixture was left standing, the suspension was quickly separated into layers, the supernatant was sucked off, and the precipitate was washed twice with hexane at room temperature. Add 120ml of hexane, cool the system to 0°C, slowly add 6ml of titanium tetrachloride dropwise, then raise the temperature to 60°C, and react for 2 hours. Stop stirring, let it stand, the suspension will be layered quickly, and the supernatant will be pumped out. After the precipitate is washed ...

Embodiment 3

[0058] (1) Preparation of catalyst components

[0059] In the reactor fully replaced by high-purity nitrogen, add 4.0g spherical carrier MgCl in sequence 2 2.6C 2 h 5 OH, 100ml hexane, cooled down to -10°C with stirring, added dropwise 30ml triethylaluminum hexane solution (triethylaluminum: 1.2M) and 0.5ml ethyl benzoate, 0.5ml butyl acrylate, 5mg over Diisopropyl dicarbonate was oxidized, then the temperature was raised to 50 °C and the reaction was maintained for 2 hours. Stirring was stopped and the mixture was left standing, the suspension was quickly separated into layers, the supernatant was sucked off, and the precipitate was washed twice with hexane at room temperature. Add 100ml of hexane, cool the system to 0°C, slowly add 6ml of titanium tetrachloride dropwise, then raise the temperature to 60°C, and react for 2 hours. Stop stirring, let it stand, the suspension will be layered quickly, and the supernatant will be pumped out. After the precipitate is washed twi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com