Multi-layer heterogeneous antireflection film solar cell

A technology of solar cells and anti-reflection coatings, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of adverse effects on cell conversion efficiency, inability to be effectively used, and easy breakage, and achieve excellent PID-Free performance and improve Effects of improving physical properties, electrical properties, and photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

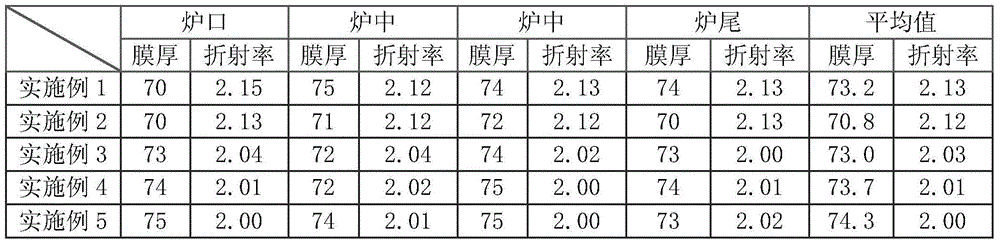

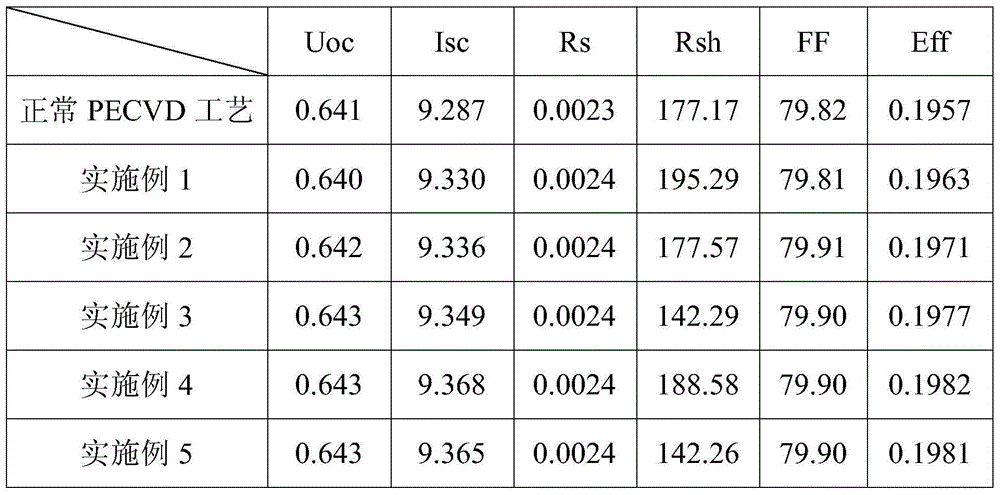

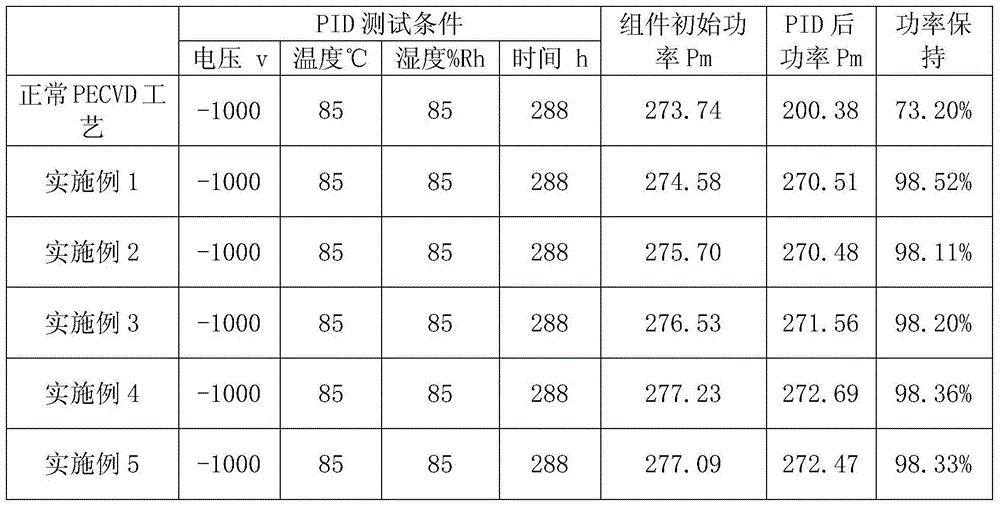

[0024] Put the 156.75mm*205mm silicon wafer after etching and cleaning into the PECVD furnace tube, and deposit the following films in sequence according to the steps: the first step is SiO 2Membrane → second step SiN x Membrane → third step SiO x N y Membrane → Step 4 SiO 2 membrane. Wherein the first step process parameter is: N 2 O flow 4000sccm, SiH 4 The flow rate is 500sccm, the RF power is 3000W, the reaction pressure is 1500mT, the time is 200 seconds, and the temperature is 450 degrees; the process parameters of the second step are: SiH 4 The flow rate is 800sccm, NH 3 The flow rate is 5000sccm, the radio frequency power is 4000W, the reaction pressure is 1700mT, the time is 300 seconds, and the temperature is 450 degrees; the process parameters of the third step are: N 2 O flow 3000sccm, SiH 4 The flow rate is 500sccm, NH 3 The flow rate is 1000sccm, the radio frequency power is 3000W, the reaction pressure is 1500mT, the time is 100 seconds, and the tempera...

Embodiment 2

[0026] Put the 156.75mm*205mm silicon wafer after etching and cleaning into the PECVD furnace tube, and deposit the following films in sequence according to the steps: the first step is SiO 2 Membrane → second step SiN x Membrane → third step SiO x N y Membrane → Step 4 SiO 2 membrane. Wherein the first step process parameter is: N 2 O flow 4000sccm, SiH 4 The flow rate is 500sccm, the RF power is 3000W, the reaction pressure is 1500mT, the time is 100 seconds, and the temperature is 450 degrees; the process parameters of the second step are: SiH 4 The flow rate is 800sccm, NH 3 The flow rate is 5000sccm, the radio frequency power is 4000W, the reaction pressure is 1700mT, the time is 400 seconds, and the temperature is 450 degrees; the process parameters of the third step are: N 2 O flow 3000sccm, SiH 4 The flow rate is 500sccm, NH 3 The flow rate is 1000sccm, the radio frequency power is 3000W, the reaction pressure is 1500mT, the time is 100 seconds, and the temper...

Embodiment 3

[0028] Put the 156.75mm*205mm silicon wafer after etching and cleaning into the PECVD furnace tube, and deposit the following films in sequence according to the steps: the first step is SiO 2 Membrane → second step SiN x Membrane → third step SiO x N y Membrane → Step 4 SiO 2 membrane. Wherein the first step process parameter is: N 2 O flow 4000sccm, SiH 4 The flow rate is 500sccm, the RF power is 3000W, the reaction pressure is 1500mT, the time is 100 seconds, and the temperature is 450 degrees; the process parameters of the second step are: SiH 4 The flow rate is 600sccm, NH 3 The flow rate is 6000sccm, the radio frequency power is 4000W, the reaction pressure is 1700mT, the time is 400 seconds, and the temperature is 450 degrees; the process parameters of the third step are: N 2 O flow 3000sccm, SiH 4 The flow rate is 500sccm, NH 3 The flow rate is 1000sccm, the radio frequency power is 3000W, the reaction pressure is 1500mT, the time is 100 seconds, and the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com