Preparation method of super-hydrophobic silicon dioxide film

A super-hydrophobic, thin-film technology, applied in electrolytic coating, electrophoretic plating, coating, etc., to achieve the effect of simple operation, low requirements on the surface shape of the substrate, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A preparation method for superhydrophobic film, comprising the following steps:

[0019] 1) After the metal substrate is sanded to 600 meshes, it is taken out after ultrasonication in ethanol for 10 minutes, washed and dried with tap water and deionized water, and then put into a 60 oC constant temperature drying box for use;

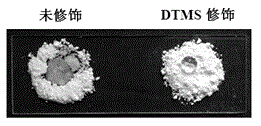

[0020] 2) Weigh nano-scale SiO 2 Disperse the powder in an ammonia solution with a pH of 8-12, stir it magnetically for 1 hour and set aside; add hydrophobic long-chain silane in another container and disperse it in ethanol or acetone, stir it magnetically for 1 hour and set aside, add the latter solution dropwise Into the previous solution, magnetically stirred for 6 hours to form a uniform suspension, aged for 2 to 6 hours, centrifuged, and the obtained white powder was dried in an oven at 60 °C to obtain superhydrophobic SiO 2 Powder; add 1~3g nano-sized SiO to every 100ml ethanol or acetone 2 powder and 2-10 mL hydrophobic long-chain silane...

Embodiment 1

[0025] The substrate is a commercial aluminum alloy substrate AA2024-T3, which is sanded to 600 mesh, ultrasonicated in ethanol for 10 minutes, taken out, cleaned and dried with tap water and deionized water, and then placed in a 60 oC constant temperature drying oven for use.

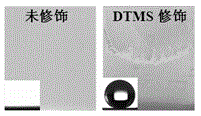

[0026] Preparation of Hydrophobic SiO 2 Solution preparation: solution 1 composition: weigh 1g nano-SiO 2 The powder is dispersed in a solution with pH = 8, and the pH of the solution is adjusted by using ammonia water, and it is used after magnetic stirring for 1 hour; the composition of solution 2: 2ml of hydrophobic silane or other hydrophobic polymers dispersed in 100ml of organic solvent ethanol, After 1 hour of magnetic stirring, it is ready for use; solution 3: add the above solution 2 to solution 1 drop by drop, form a uniform suspension after 6 hours of magnetic stirring, and age for 2 hours for use. The above solution 3 was separated by centrifugation, the rotation speed was controlled at 10...

Embodiment 2

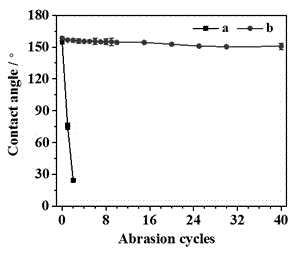

[0032] Other steps are similar to embodiment 1 in the present embodiment, but preparation hydrophobic SiO 2 During the preparation process of the solution, the composition of the solution 1 is as follows: weigh 3g of nano-SiO 2 The powder is dispersed in a solution with pH = 12, and the pH of the solution is adjusted by ammonia water, and it is used after magnetic stirring for 1 hour; the composition of solution 2: 10ml of hydrophobic silane or other hydrophobic polymers dispersed in 100ml of organic solvent acetone, After 1 hour of magnetic stirring, it is ready for use; the substrate is a commercial aluminum alloy substrate AA2024-T3, and the hydrophobic SiO 2The mass fraction is 10%, and the resin binder content in the electrophoretic deposition solution is 10.0%. The electrophoretic deposition condition was 80 V, and the tested contact angle was 158.6 o.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com