A method for preparing metal surface film with rapid self-healing ability

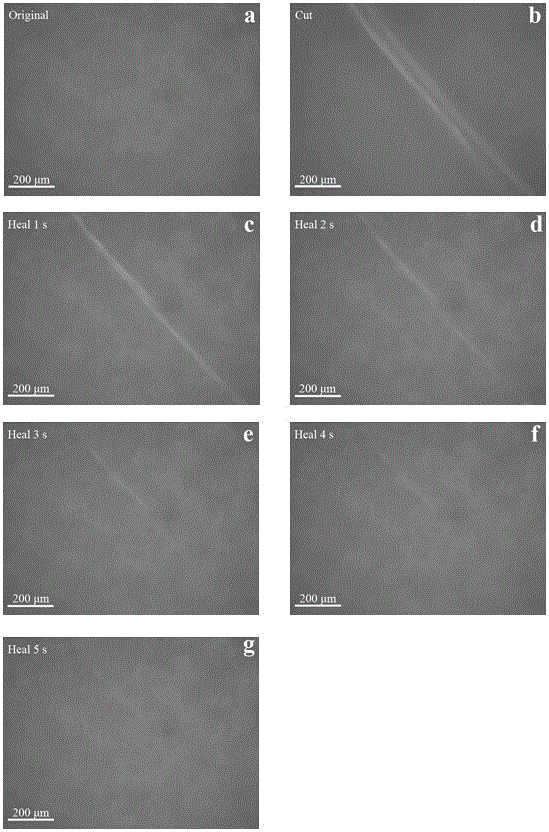

A metal surface, self-repair technology, applied in the direction of metal material coating technology, etc., can solve the problem of weak self-repair ability of the film layer, and achieve the effect of overcoming weak self-repair ability, convenient operation, and fast self-repair speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing an AZ31 magnesium alloy surface film with fast self-repairing ability, the specific steps are as follows:

[0024] ①Hydrogen peroxide hydrothermal treatment: Immerse the clean AZ31 magnesium alloy workpiece in a reaction kettle filled with a hydrogen peroxide solution with a concentration of 1% by mass, seal the reaction kettle and place it in an oven at 100°C for 3 hours, then cool to Room temperature, take out the workpiece, rinse with pure water, and blow dry with compressed air;

[0025] ② Sol coating and curing: Apply the polymer sol evenly to the surface of the workpiece after ① treatment. The ratio of the volume of the sol to the area of the metal workpiece to be treated is 50ml: 1m 2 , drying the workpiece at 60°C for 28 hours to obtain the AZ31 magnesium alloy surface film with rapid self-healing ability;

[0026] The preparation steps of the polymer sol are as follows: adding 20 grams of cetyltrimethylammonium bromide into 100 millili...

Embodiment 2

[0031] A method for preparing a pure copper surface film with rapid self-repair ability, the specific steps are as follows:

[0032] ①Hydrogen peroxide hydrothermal treatment: immerse the clean pure copper workpiece in a reaction kettle filled with a hydrogen peroxide solution with a concentration of 3% by mass, seal the reaction kettle and place it in an oven at 120°C for 5 hours, then cool to room temperature , Take out the workpiece, rinse it with pure water, and dry it with compressed air;

[0033] ② Sol coating and curing: Apply the polymer sol evenly to the surface of the workpiece after ① treatment. The ratio of the volume of the sol to the area of the metal workpiece to be treated is 50ml: 1m 2 , drying the workpiece at 40°C for 36 hours to obtain a pure copper surface film with rapid self-healing ability;

[0034] The preparation steps of the polymer sol are as follows: adding 25 grams of cetyltrimethylammonium bromide into 100 milliliters of a concentration of 0.2...

Embodiment 3

[0037] A method for preparing a 2024 aluminum alloy surface film with rapid self-repairing capability, the specific steps are as follows:

[0038] ①Hydrogen peroxide hydrothermal treatment: immerse the clean 2024 aluminum alloy workpiece in a reaction kettle filled with a hydrogen peroxide solution with a concentration of 2% by mass, seal the reaction kettle and place it in an oven at 110°C for 4 hours, then cool to Room temperature, take out the workpiece, rinse with pure water, and blow dry with compressed air;

[0039] ② Sol coating and curing: Apply the polymer sol evenly to the surface of the workpiece after ① treatment. The ratio of the volume of the sol to the area of the metal workpiece to be treated is 50ml: 1m 2 , drying the workpiece at 50°C for 30 hours to obtain a 2024 aluminum alloy surface film with rapid self-healing ability;

[0040]The preparation steps of the polymer sol are: adding 30 grams of cetyltrimethylammonium bromide into 100 milliliters of a conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com