Children ampicillin sodium compound entity and pharmaceutical preparation thereof

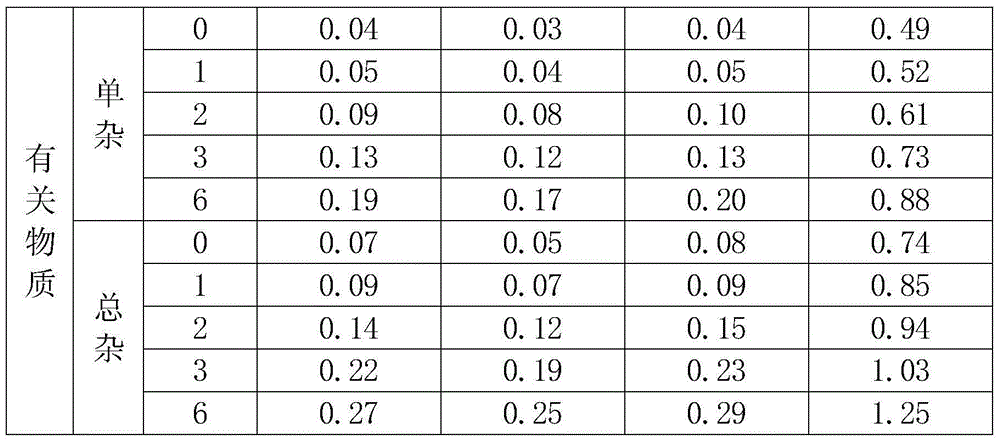

A technology of ampicillin sodium and ampicillin, applied in the field of pharmaceutical compounds, can solve the problems of poor stability of ampicillin sodium, occurrence of degradation products, easy discoloration of appearance, etc., and achieve the effects of less allergy, less impurities and good clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 527ml of dichloromethane and 123ml of triethylamine into the reactor, stir evenly, cool down to 0°C, add 200g of ampicillin, and stir until completely dissolved. After the solution was sterilized by membrane filtration, the pipeline through which ampicillin passed during the filtration was rinsed with a mixture of 260ml of dichloromethane and 16ml of triethylamine, and the filtrate and washing solution were combined.

[0030] Add 140 grams of sodium isooctanoate to 609 ml of methyl acetate, and stir until completely dissolved. After the solution is sterilized by membrane filtration, the pipeline through which sodium isooctanoate passes through is rinsed with 200 ml of methyl acetate, and the filtrate and washing liquid are combined.

[0031] Cool the ampicillin solution to -5°C, add 1% sodium isooctanoate solution under rapid stirring, and after stirring for 10 minutes, slowly raise the temperature of the solution to 15°C while stirring, stir for 30 minutes, keep wa...

Embodiment 2

[0036] Add 527ml of dichloromethane and 123ml of triethylamine into the reactor, stir evenly, cool down to 0°C, add 200g of ampicillin, and stir until completely dissolved. After the solution was sterilized by membrane filtration, the pipeline through which ampicillin passed during the filtration was rinsed with a mixture of 260ml of dichloromethane and 16ml of triethylamine, and the filtrate and washing solution were combined.

[0037] Add 140 grams of sodium isooctanoate to 609 ml of methyl acetate, and stir until completely dissolved. After the solution is sterilized by membrane filtration, the pipeline through which sodium isooctanoate passes through is rinsed with 200 ml of methyl acetate, and the filtrate and washing liquid are combined.

[0038] Cool the ampicillin solution to -8°C, add 2% sodium isooctanoate solution under rapid stirring, stir for 10 minutes, slowly increase the solution temperature to 12°C while stirring, stir for 30 minutes, keep warm at 12°C, and th...

Embodiment 3

[0043]Add 527ml of dichloromethane and 123ml of triethylamine into the reactor, stir evenly, cool down to 0°C, add 200g of ampicillin, and stir until completely dissolved. After the solution was sterilized by membrane filtration, the pipeline through which ampicillin passed during the filtration was rinsed with a mixture of 260ml of dichloromethane and 16ml of triethylamine, and the filtrate and washing solution were combined.

[0044] Add 140 grams of sodium isooctanoate to 609 ml of methyl acetate, and stir until completely dissolved. After the solution is sterilized by membrane filtration, the pipeline through which sodium isooctanoate passes through is rinsed with 200 ml of methyl acetate, and the filtrate and washing liquid are combined.

[0045] Cool the ampicillin solution to -10°C, add 3% sodium isooctanoate solution under rapid stirring, stir for 10 minutes, slowly increase the solution temperature to 10°C while stirring, stir for 30 minutes, keep warm at 10°C, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com