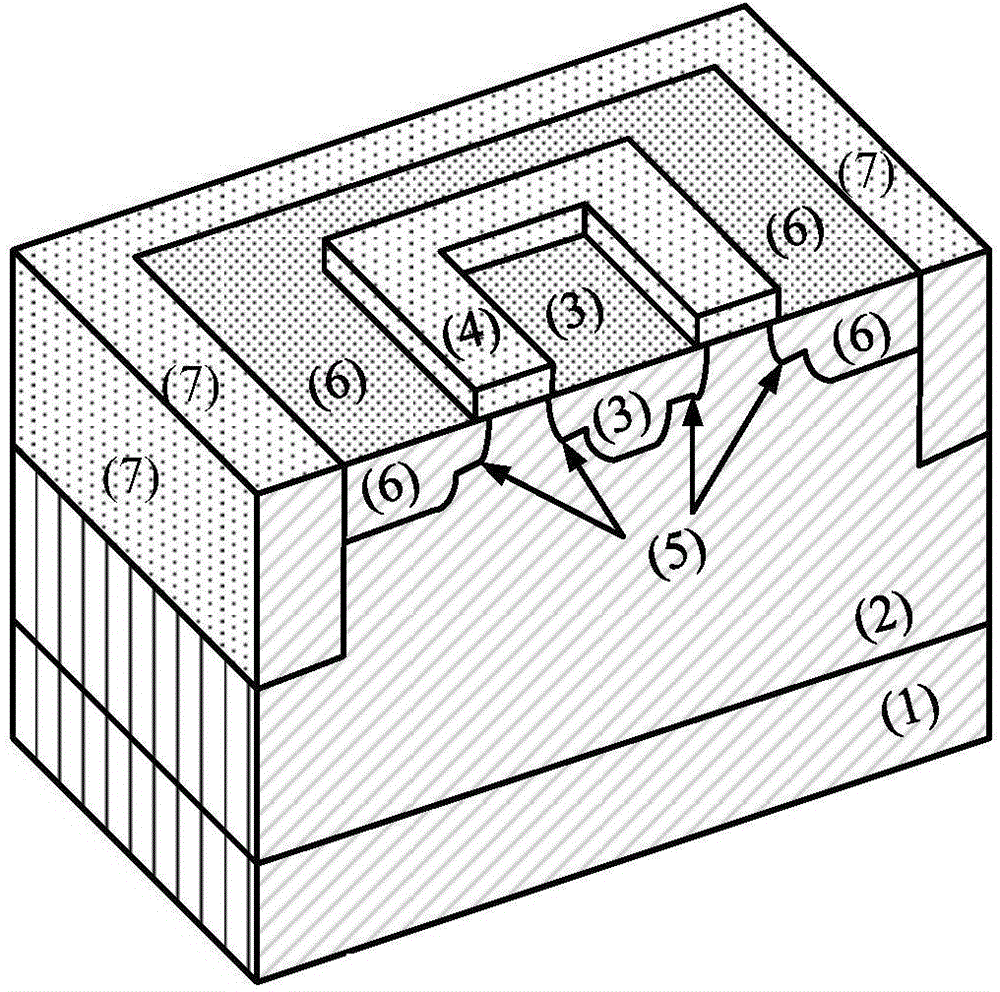

Gate-all-around anti-irradiation MOS field effect transistor based on 65 nm technology

A field effect tube and anti-irradiation technology, applied in transistors, electrical components, circuits, etc., can solve problems that threaten circuit and system reliability, drift of device threshold voltage, increase of off-state leakage current, etc., and achieve strong anti-total dose Irradiation capability, off-state leakage current reduction, effect of leakage current reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0045] Example 1, making a 65nm MOS field effect transistor with a square gate ring.

[0046] Step 1, growing an epitaxial layer.

[0047] 1.1) Using the method of chemical vapor deposition at a temperature of 650 ° C with SiH 4 An epitaxial layer with a thickness of 1200nm is grown on a P-type substrate as a reactant;

[0048] 1.2) The depth of the epitaxial layer is 150nm, the concentration is 1×10 18 cm -3 doping to adjust the channel concentration.

[0049] Step 2, etching the isolation groove.

[0050] 2.1) Thin SiO with a thickness of 10nm is thermally oxidized on the epitaxial layer at a temperature of 1250°C by dry oxygen process 2 buffer layer, then the SiO 2 25nm thick Si grown on the buffer layer 3 N 4 The protective layer;

[0051] 2.2) In Si 3 N 4 A layer of photoresist is made on the protective layer, and the Si 3 N 4 Make a square ring-shaped isolation groove window on the photoresist around the protective layer and etch to form an isolation groove ...

example 2

[0071] Example 2, manufacturing a 65nm MOS field effect transistor with a rectangular gate ring.

[0072] Step 1, using chemical vapor deposition method at a temperature of 600 ° C with SiH 4 An epitaxial layer with a thickness of 900nm was grown on a P-type substrate as a reactant, and then the depth of the epitaxial layer was 125nm, and the concentration was 7×10 17 cm -3 doping to adjust the channel concentration.

[0073] Step 2, etching the isolation groove.

[0074] Thin SiO with a thickness of 8 nm was grown by thermal oxidation at a temperature of 1200 °C on the epitaxial layer by a dry oxygen process 2 buffer layer, then the SiO 2 22nm thick Si grown on the buffer layer 3 N 4 protective layer; in Si 3 N 4 A layer of photoresist is made on the protective layer, and the Si 3 N 4 Make a rectangular ring-shaped isolation groove window on the photoresist around the protective layer and etch to form an isolation groove with a width of 400nm; after the etching is c...

example 3

[0086] Example 3, manufacturing a 65nm MOS field effect transistor with a circular gate ring.

[0087] Step A, growing an epitaxial layer.

[0088] A1) using chemical vapor deposition method at a temperature of 550 ° C with SiH 4 An epitaxial layer with a thickness of 600nm is grown on a P-type substrate as a reactant;

[0089] A2) The depth of the epitaxial layer is 100nm, the concentration is 2×10 17 cm -3 doping to adjust the channel concentration.

[0090] Step B, etching the isolation groove.

[0091] B1) Thin SiO with a thickness of 5 nm is thermally oxidized on the epitaxial layer at a temperature of 1100 ° C by a dry oxygen process 2 buffer layer, on SiO 2 20nm thick Si grown on the buffer layer 3 N 4 The protective layer;

[0092] B2) in Si 3 N 4 A layer of photoresist is made on the protective layer, and the Si 3 N 4 A circular ring-shaped isolation groove window is made on the photoresist around the protective layer and etched to form an isolation groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com