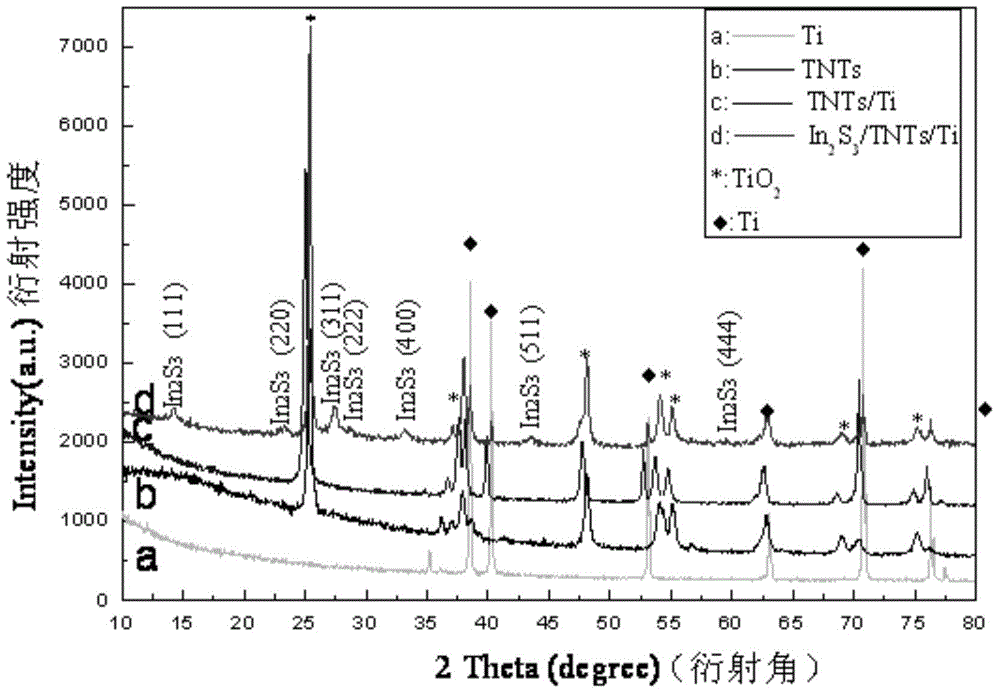

Preparation method of composite light anode of titanium dioxide nanotube array with wide light intensity application scope

A technology of nanometer dioxide and nanotube array is applied in the field of preparation of nanometer tube array composite photoanode, which can solve problems such as poor photoelectric conversion performance, and achieve enhanced photoelectric cell performance, improved photovoltage value, and excellent photoelectric conversion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a nanotube array composite photoanode with a wide light intensity application range, the specific method is:

[0028] a. Sheet texture of titanium foil

[0029] Cut and polish the titanium foil, use coarse sandpaper to remove impurities and oxides on the surface layer, and then use fine sandpaper to smooth it. After grinding, because there are impurities left in the grinding, it must be washed with clean water to remove surface impurities, and then washed with ethanol to remove residual lipids generated by surface contact, and then washed again with a mixed solution of ethanol, deionized water and acetone, and finally Dry by cold air.

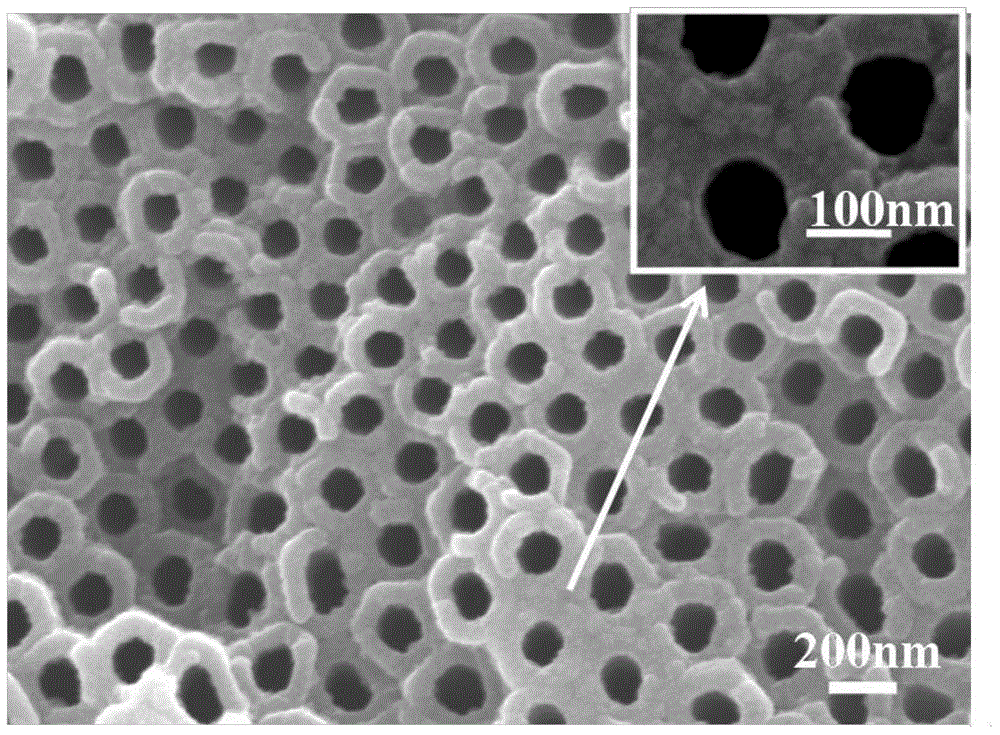

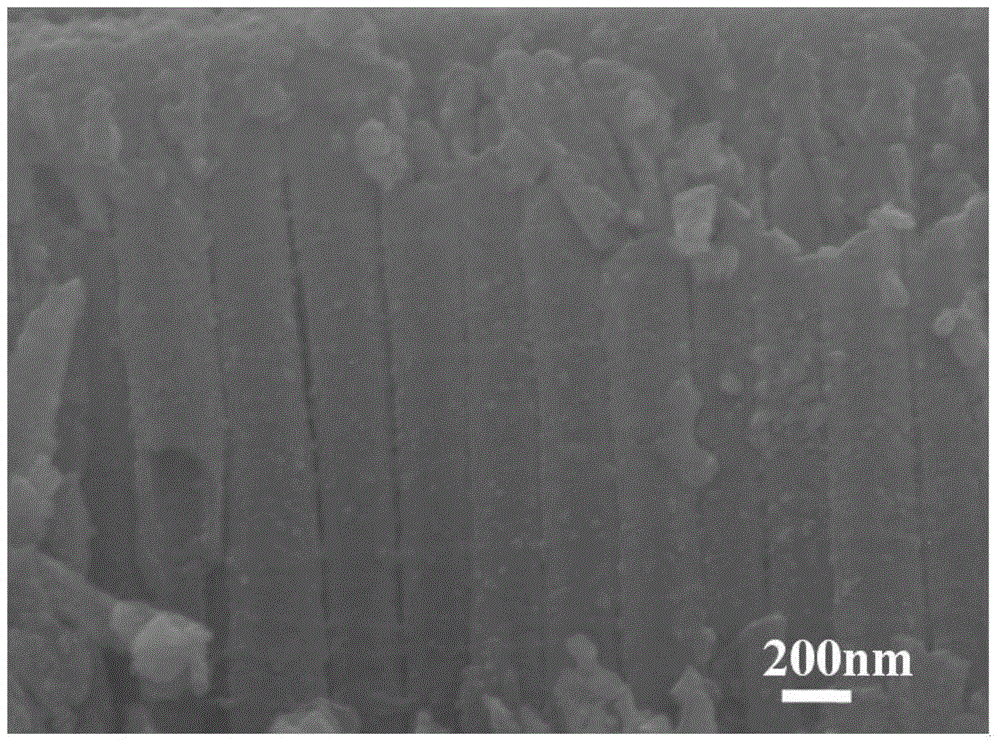

[0030] b. Synthesis of titania nanotube arrays

[0031] The anode of the oxidation reaction is a titanium foil, and the cathode is a platinum sheet. There is a fixed value of 3cm between them, and the installed cathode and anode are placed in 0.25wt% NH 4 In the ethylene glycol solution of F, add 60V DC and it i...

Embodiment 2 4

[0042] Change the operating range of photochemical solar cells to 50mW / cm respectively 2 , 25mW / cm 2 , 5mW / cm 2 , to test whether the battery can continue to be effective. As can be seen from the table below, with N719 / In 2 S 3 / Photochemical solar cells based on titanium dioxide nanotube arrays / Ti substrates as composite photoanodes in the light intensity range of 25-100mW / cm 2 Both can show high conversion efficiency, which shows that this kind of solar cell has strong adaptability to the environment, and can be applied to areas with strong or weak light.

[0043] Table 1

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com