Preparation method of self-supporting PEDOT/PSS transparent conductive film

A transparent conductive film, self-supporting technology, used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of film surface smoothness and photoelectric properties, can not use self-supporting film alone, limit the use performance and other problems. Good conductivity, smooth surface and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Ultrasonic clean the PET substrate with detergent water, absolute ethanol, and deionized water for 15 minutes respectively, and dry it with a hair dryer for later use;

[0033] (2) Prepare PEDOT / PSS dispersion doped with polyethylene glycol 4000 (1 wt%) fluorocarbon surfactant Capstone FS-30 (1 wt%), and stir evenly at room temperature;

[0034] (3) Coat the film on the cleaned PET substrate at room temperature with a motor speed of 100.8rpm and No.9 wire bar, heat and dry at 120°C to obtain a film with PET as the substrate;

[0035] (4) Cut a piece of appropriate size and place it in a petri dish, wash it with formic acid to separate the film from the PET substrate, and wash it with deionized water for 5 times;

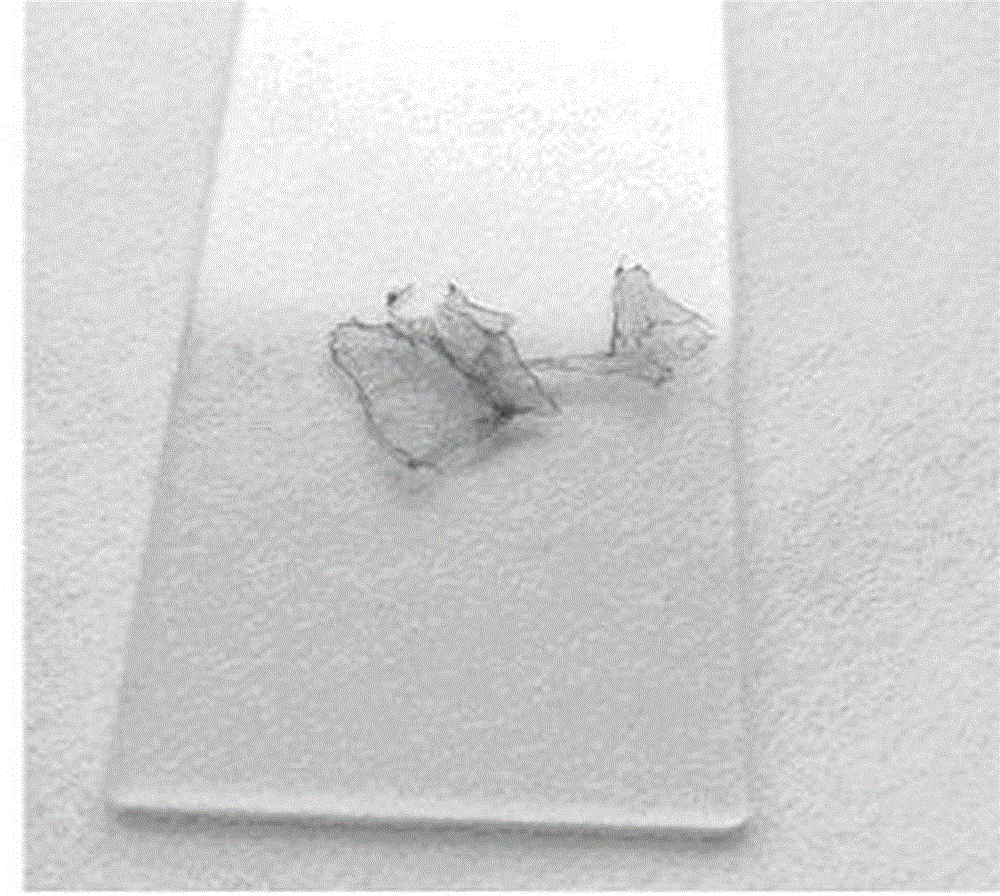

[0036] (5) Freeze-dry to obtain an unsupported film.

Embodiment 2

[0038] (1) Ultrasonic clean the PET substrate with detergent water, absolute ethanol, and deionized water for 15 minutes respectively, and dry it with a hair dryer for later use;

[0039] (2) Prepare PEDOT / PSS dispersion doped with ethylene glycol (7 wt%), polyethylene glycol 4000 (1 wt%), fluorocarbon surfactant Capstone FS-30 (1 wt%), and stir at room temperature Uniform;

[0040] (3) Coat the film on the cleaned PET substrate at room temperature with a motor speed of 100.8rpm and No.9 wire bar, heat and dry at 120°C to obtain a film with PET as the substrate;

[0041] (4) Cut a piece of appropriate size and place it in a petri dish, wash it with deionized water to separate the film from the PET substrate, and then rinse it with deionized water for 5 times;

[0042] (5) Heat and dry to obtain an unsupported film.

Embodiment 3

[0044] (1) Ultrasonic clean the PET substrate with detergent water, absolute ethanol, and deionized water for 15 minutes respectively, and dry it with a hair dryer for later use;

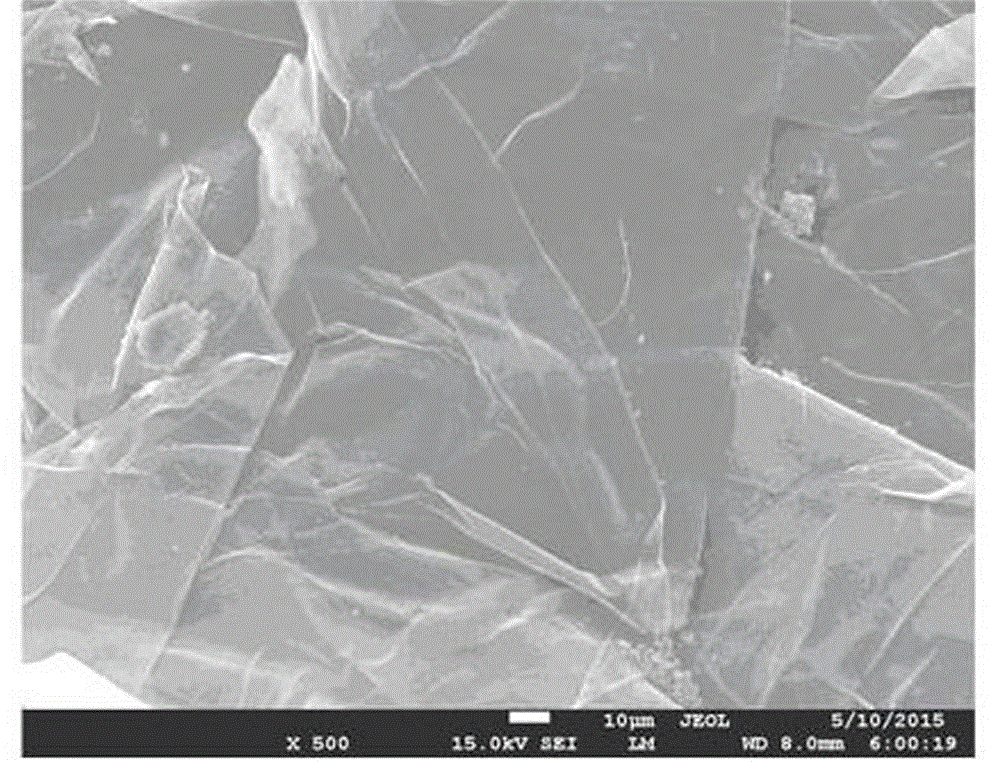

[0045] (2) Prepare doped ethylene glycol (7 wt%), polyethylene glycol 4000 (1 wt%), halloysite nanotubes (2 wt%), fluorocarbon surfactant Capstone FS-30 (1 wt% ) PEDOT / PSS dispersion liquid, stir evenly at room temperature;

[0046] (3) Coat the film on the cleaned PET substrate at room temperature with a motor speed of 100.8rpm and No.9 wire bar, heat and dry at 120°C to obtain a film with PET as the substrate;

[0047] (4) Cut a piece of appropriate size and place it in a petri dish, wash it with deionized water to separate the film from the PET substrate, and then rinse it with deionized water for 5 times;

[0048] (5) It can be obtained from the support film by heating and drying.

[0049]The reagent PEDOT / PSS used in the above examples is poly(3,4-ethylenedioxythiophene)-poly(styrenesulfoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com