Ocean polymetallic nodule and arsenious gold ore mixing pretreatment method

A polymetallic nodule and pretreatment technology, applied in the field of non-ferrous metallurgy, can solve the problems of long gold extraction process, low gold recovery rate, and low utilization rate of arsenic gold ore, and achieve improved leaching rate, high extraction rate, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

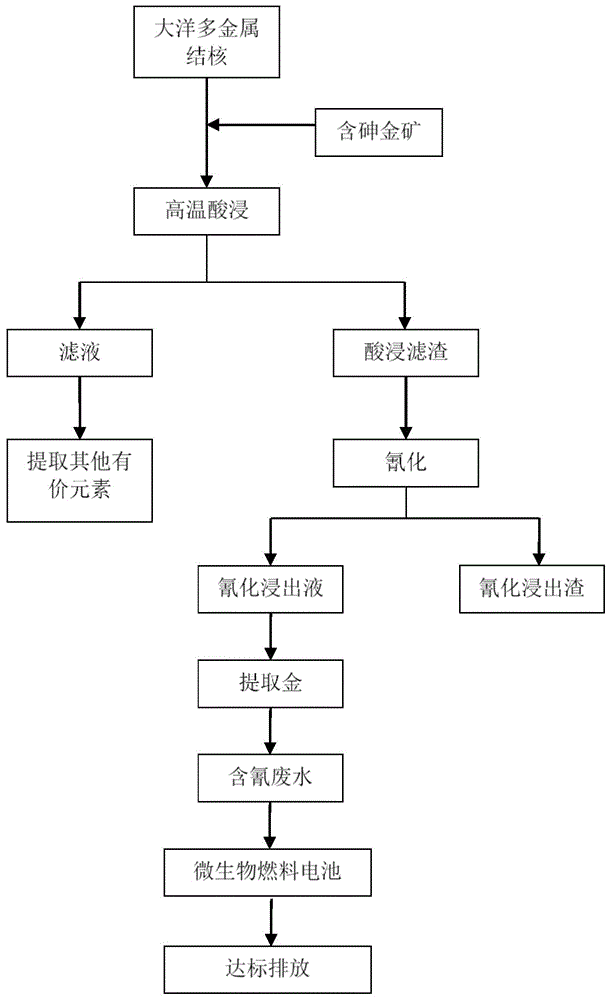

Method used

Image

Examples

Embodiment 1

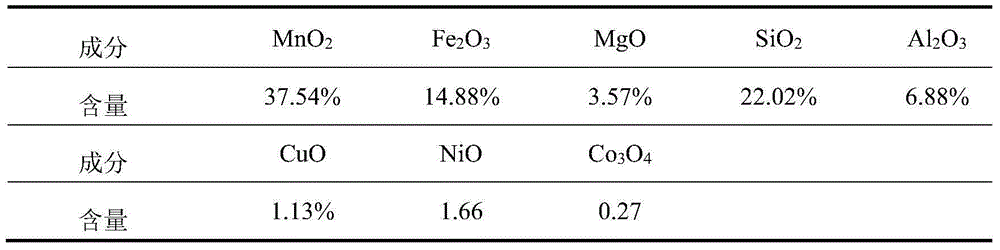

[0034] An arsenic-containing gold concentrate in Yangshan, Gannan, containing 45.67g / t of gold, and other chemical components are shown in the table below.

[0035]

[0036] Take 100g of oceanic polymetallic nodules and 200g of arsenic-containing gold concentrate and mix evenly (the mass ratio of oceanic polymetallic nodules to arsenic-containing gold concentrate is 0.5:1), add 40% H 2 SO 4 The solution was reacted at 90° C. in a water bath for 3 hours. After cooling, it was taken out and filtered. The manganese leaching rate was 93.05%, the iron leaching rate was 92.28%, the cobalt leaching rate was 92.39%, the nickel leaching rate was 91.77%, and the copper leaching rate was 87.54%. The filter residue was slurried with sodium cyanide solution and calcium oxide. The pH of the slurry was 9, the concentration of sodium cyanide was 5%, aerated and stirred and leached for 48 hours, and the gold leaching rate was 72.16%. Add sulfuric acid to the reverse osmosis concentrate to ...

Embodiment 2

[0038] An arsenic-containing gold mine in Henan contains 36.54g / t of gold, and other chemical components are shown in the table below.

[0039]

[0040] Take 1000g of oceanic polymetallic nodules and 200g of arsenic-containing gold concentrate and mix evenly (the mass ratio of oceanic polymetallic nodules to arsenic-containing gold concentrate is 5:1), add 30% H 2 SO 4 The solution was reacted at 150° C. in an oil bath for 6 hours. After cooling, it was taken out and filtered. The manganese leaching rate was 56.17%, the iron leaching rate was 55.42%, the cobalt leaching rate was 58.06%, the nickel leaching rate was 55.69%, and the copper leaching rate was 51.30%. The filter residue was mixed with sodium cyanide solution and calcium oxide, the pH of the slurry was 11, the concentration of sodium cyanide was 5%, aeration and stirring leaching for 96 hours, the gold leaching rate was 93.87%. Add sulfuric acid to the reverse osmosis concentrate to adjust the pH=1.5, and then t...

Embodiment 3

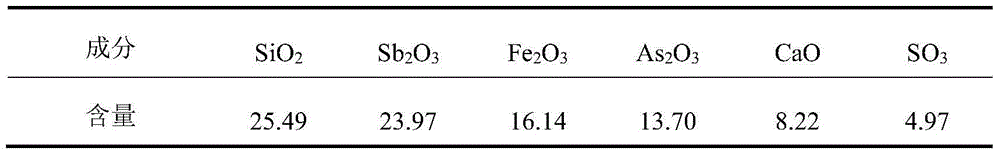

[0042] The arsenic-bearing gold mine in Guigang, Guangxi contains 70.7g / t of gold, and other chemical compositions are shown in the table below.

[0043]

[0044] Take 300g of oceanic polymetallic nodules and 200g of arsenic-containing gold concentrate and mix evenly (mass ratio of oceanic polymetallic nodules to arsenic-containing gold concentrate is 1.5:1), add 5% H 2 SO 4The solution was reacted at 50°C in a water bath for 4 hours, and after cooling, it was taken out and filtered. The manganese leaching rate was 77.8%, the iron leaching rate was 76.59%, the cobalt leaching rate was 78.02%, the nickel leaching rate was 76.43%, and the copper leaching rate was 72.95%. The filter residue was mixed with sodium cyanide solution and calcium oxide. The pH of the slurry was 10, and the concentration of sodium cyanide was 5%. After aeration and stirring for leaching for 24 hours, the gold leaching rate was 84.65%. Add sulfuric acid to the reverse osmosis concentrate to adjust pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com