A kind of preparation method of high wear-resistant iron-based composite material

An iron-based composite material, high wear resistance technology, applied in the field of iron-based composite materials, can solve the problems affecting the wear resistance of composite materials, ceramic particles falling off, etc., achieve high hardness and high temperature strength, convenient arrangement, increase volume fraction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

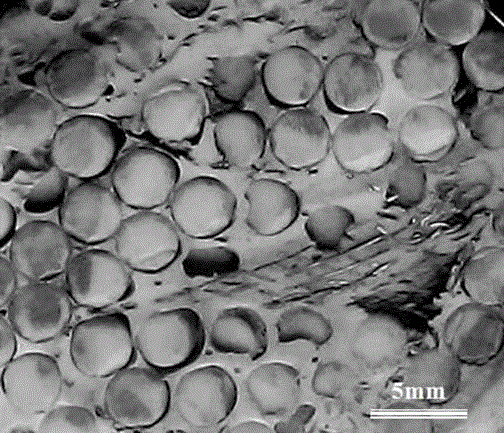

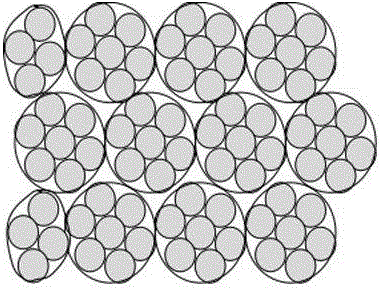

[0018] This embodiment specifically implements a high-wear-resistant iron-based composite material and its preparation method. The process is: a cylindrical ceramic with a diameter of 3 mm, which is made of fused zirconia corundum, has good toughness and thermal stability, and high hardness and high-temperature strength. The material is electroless nickel-plated, and the thin ceramic rods after nickel plating are closely arranged in the radial direction to form a small unit with a circular cross-section perpendicular to the length direction, and the wires with a diameter of 0.6mm made of industrial pure aluminum are bundled by conventional Method The ceramic thin rods of one unit are bundled together at both ends, and then the same small units are closely arranged in a rectangle with a length of 120 mm and a width of 60 mm. The ceramic thin rods are perpendicular to the surface to be worn, and the adjacent units are The aluminum wires used for bundling are connected together by...

Embodiment 2

[0021] This embodiment specifically implements a high wear-resistant iron-based composite material and its preparation method. The process is as follows: the yttrium oxide-stabilized alumina with a diameter of 1mm is made of good toughness, high hardness and high-temperature strength, and good thermal stability. The cylindrical ceramic material is electroless nickel-plated, and the thin ceramic rods are closely arranged in the radial direction to form a small unit with a triangular cross-section perpendicular to the length direction, and a wire-like material with a diameter of 0.3mm made of industrial pure aluminum is used for conventional binding. Bundle the thin ceramic rods of one unit together from both ends, and then arrange the same small units closely into a rectangle with a length of 100 mm and a width of 50 mm. The thin ceramic rods are perpendicular to the surface to be worn, and the adjacent units The aluminum wires used for bundling are connected together by laser w...

Embodiment 3

[0023] This embodiment specifically implements a high-wear-resistant iron-based composite material and its preparation method. The process is: the tungsten carbide ceramics with good toughness, high hardness and high temperature strength, and good thermal stability have a diameter of 1.5 mm. The cylindrical ceramic material is electroless nickel-plated, and the thin ceramic rods are closely arranged in the radial direction to form a small unit with a square cross-section perpendicular to the length direction, and the wire-like material with a diameter of 0.4mm made of industrial pure aluminum is used for conventional binding. Method Bundle the thin ceramic rods of one unit together by the two ends respectively, and then arrange the same small units closely into a square with a side length of 90mm, in which the thin ceramic rods are perpendicular to the surface to be worn, and the adjacent units The aluminum wires used for bundling are connected together by argon arc welding, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com