Machining method for preparing Al/Mg/Al alloy composite board by rolling

A processing method and composite plate technology, applied in the direction of metal rolling, temperature control, etc., can solve problems such as ineffectiveness, insufficient diffusion, and elaboration of annealing process, to eliminate stress, improve interface bonding force, and atomic diffusion ability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The magnesium alloy and aluminum to be rolled are AZ31 and pure aluminum 1070, respectively.

[0023] Composite rolling the alloy plate:

[0024] a) Cutting the plates to be compound-rolled into shapes of equal size, cleaning and polishing the surface.

[0025] b) Sandwich a magnesium plate between two aluminum plates, then punch holes in the four corners and fix them with rivets.

[0026] c) Perform single-pass compound rolling on the fixed plate, the rolling reduction rate is 50%, the rolling temperature is 350° C., and the holding time before rolling is 15 minutes.

[0027] Composite panels were not annealed.

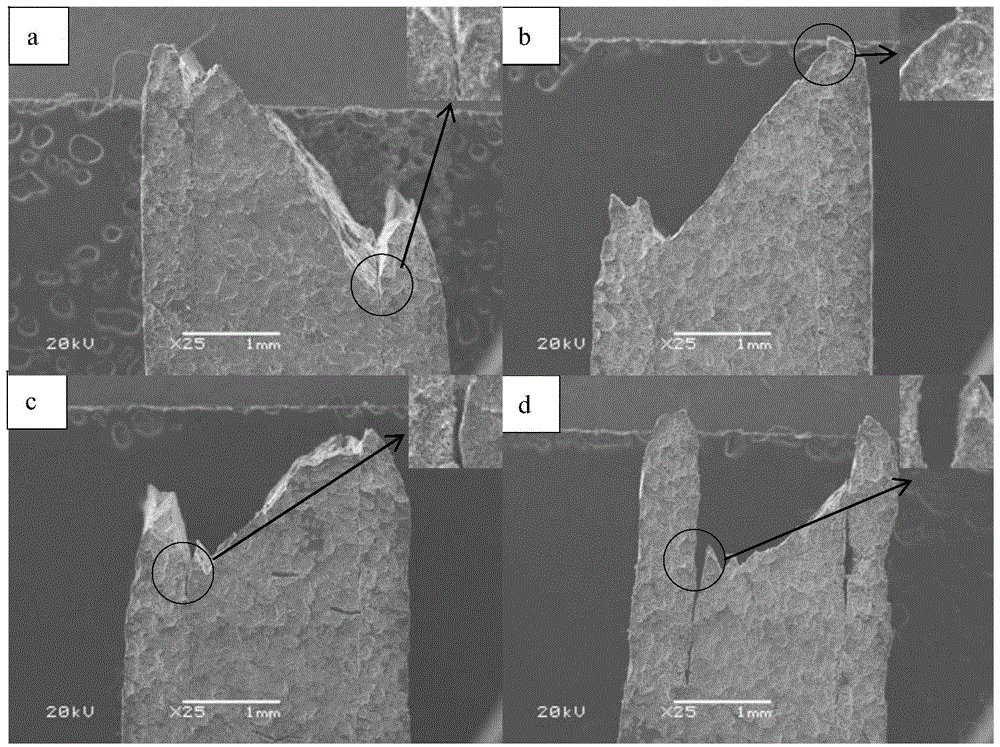

[0028] Obtain a kind of composite plate, under room temperature, tensile strength is 256MPa, and elongation is 11.1%, but slight interfacial delamination occurs in stretching process, and its tensile fracture scanning top view is as follows figure 1 (a) shown.

Embodiment 2

[0030] The magnesium alloy and aluminum to be rolled are AZ31 and pure aluminum 1070, respectively.

[0031] Composite rolling the alloy plate:

[0032] a) Cutting the plates to be compound-rolled into shapes of equal size, cleaning and polishing the surface.

[0033] b) Sandwich a magnesium plate between two aluminum plates, then punch holes in the four corners and fix them with rivets.

[0034] c) Perform single-pass compound rolling on the fixed plate, the rolling reduction rate is 50%, the rolling temperature is 350° C., and the holding time before rolling is 15 minutes.

[0035] To anneal composite panels:

[0036] The rolled Al / Mg / Al alloy composite plate is put into a heating furnace, heated to 200° C., kept for 2 hours, and then taken out of the furnace and air-cooled.

[0037] A composite plate with good comprehensive properties was obtained. At room temperature, the tensile strength was 248MPa, the elongation was 13%, and no interfacial peeling occurred during the...

Embodiment 3

[0039] The magnesium alloy and aluminum alloy to be rolled are AZ31 and pure aluminum 1070, respectively.

[0040] Composite rolling the alloy plate:

[0041] a) Cutting the plates to be compound-rolled into shapes of equal size, cleaning and polishing the surface.

[0042] b) Sandwich a magnesium plate between two aluminum plates, then punch holes in the four corners and fix them with rivets.

[0043] c) Perform single-pass compound rolling on the fixed plate, the rolling reduction rate is 50%, the rolling temperature is 350° C., and the holding time before rolling is 15 minutes.

[0044] To anneal composite panels:

[0045] The rolled Al / Mg / Al alloy composite plate is put into a heating furnace, heated to 250° C. for 2 hours, and then taken out of the furnace and air-cooled.

[0046] A composite plate with good comprehensive performance was obtained. At room temperature, the tensile strength was 231 MPa and the elongation was 20.7%. However, a slight interfacial peeling o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com