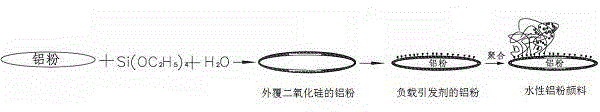

Coated modified aluminum powder pigment, and preparation method and use thereof

An aluminum powder and modification technology, applied in inorganic pigment processing, chemical instruments and methods, applications, etc., can solve the problems of aluminum powder pigments losing metallic luster, easy to fall off, and difficult to disperse aluminum powder pigments, and achieve excellent storage stability. , not easy to agglomerate, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] In terms of parts by mass (the same as below), add 1 part of aluminum powder coated with silica and 30 parts of toluene into the reactor, stir with nitrogen at room temperature, and add 0.01 part of 4,4'- Azo (4-cyanovaleric acid (3'-dimethylchlorosilane) propyl ester) and 0.1 part of triethylamine were stirred and reacted at room temperature for 12 hours, then washed with ethanol, and filtered to obtain a coated modified aluminum powder pigment.

[0059] Corrosion resistance of the coated modified aluminum powder pigment in Example 1: No hydrogen gas is precipitated in the aqueous solution in the range of pH 8-12 for 6 months.

[0060] Glossiness of the coated modified aluminum powder pigment in Example 1: after the water-based paint is cured, the surface is silver, the color is uniform, the gloss is good, and there is no flow mark.

[0061] The dispersibility of the coated modified aluminum powder pigment in this example 1: put the water-based aluminum powder pigm...

Embodiment 2

[0064] The first step: in parts by mass, add 1 part of aluminum powder coated with silica and 30 parts of toluene into the reactor, stir with nitrogen at room temperature; add 0.02 parts of 4,4'-azo ( 4-cyanovaleric acid (3'-dimethylchlorosilane) propyl ester) and 0.2 parts of triethylamine, stirred at room temperature for 12 hours; then washed with isopropanol, filtered to obtain coated modified aluminum powder pigment.

[0065] The second step: Add 1 part of coated modified aluminum powder pigment, 30 parts of methanol and 1 part of methyl acrylate into the reactor; deoxygenate the reactor under liquid nitrogen conditions, and then react in a water bath at 70 ° C for 3 hours; After filtering, washing and drying, the water-based aluminum powder pigment is obtained.

[0066] The corrosion resistance of the water-based aluminum powder pigment of the present embodiment 2: no hydrogen gas is separated out in 6 months in the aqueous solution in the range of pH8-12.

[0067] G...

Embodiment 3

[0071] The first step: in parts by mass, add 2 parts of aluminum powder coated with silica and 40 parts of toluene into the reactor, and stir with nitrogen at room temperature; add 0.05 parts of 4,4'-azo ( 4-cyanovaleric acid (3'-dimethylchlorosilane) propyl ester) and 0.2 parts of triethylamine, stirred and reacted at room temperature for 20 hours; then washed with methanol, filtered to obtain coated modified aluminum powder pigment.

[0072] The second step: add 2 parts of coated modified aluminum powder pigments, 40 parts of methanol and 1 part of methyl methacrylate into the reactor; deoxygenate the reactor under liquid nitrogen conditions, and then react in a water bath at 60 °C for 3 hours; filtered, washed, and dried to obtain water-based aluminum powder pigments.

[0073] The corrosion resistance of the water-based aluminum powder pigment of the present embodiment 3: there is no hydrogen gas precipitation in the aqueous solution in the pH8-12 range for 6 months. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com