Preparation method of nano thick sheet shape copper oxalate powder possessing angle-dependent optical effect

A technology of color-dependent and copper oxalate, applied in carboxylate preparation, organic chemistry, etc., can solve the problems of difficult control of particle size and sheet thickness and high cost, and achieve feasible preparation method, uniform particle size and high process parameters stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the nano-thick flake copper oxalate powder with the effect of different angles of the present invention specifically includes the following steps:

[0020] Step 1. Weigh the raw materials: take copper nitrate, sodium oxalate, sodium citrate, and deionized water as raw materials, in order according to 1:1-2:0.1-0.5:1×10 3 -5×10 3 Weigh the weight ratio;

[0021] Step 2. Configuration solution: the copper nitrate and sodium oxalate weighed in step 1 are respectively made into aqueous solutions, ready for use, and then the sodium citrate is added to the deionized water, and the stirring is continued to completely dissolve the sodium citrate to obtain Sodium citrate aqueous solution;

[0022] Step 3: Mix the copper nitrate aqueous solution and sodium citrate aqueous solution prepared in step 2, stir for 30-90 minutes, then add the sodium oxalate aqueous solution, stir for 5-120 minutes, add nitric acid or sodium hydroxide solution to the mixed solution to...

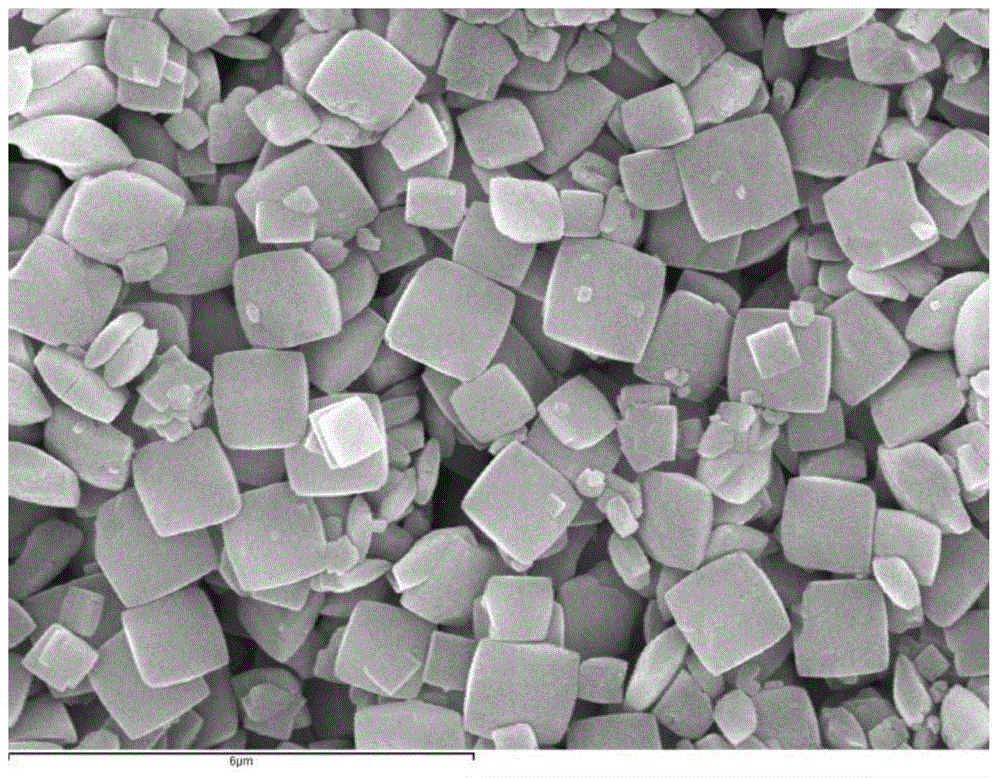

Embodiment 1

[0025] Take 90 liters of deionized water, add 10 grams of sodium citrate solid, stir to dissolve it completely, then add 5 liters of 0.1M copper nitrate solution, stir and react for 30 minutes, then add 5 liters of 0.1M concentration Sodium oxalate solution, stir and mix for 5 minutes, adjust the pH of the above mixed solution to 3.48 with 1M nitric acid or 1M sodium hydroxide solution, then continue to stir and react at room temperature for 14 hours, then filter, collect the precipitated powder, and wash it off with water Adhering impurity ions, drying the powder, you can get a well-dispersed flake copper oxalate powder material with pearlescent color, with a plane diameter of 2.8 microns and a thickness of about 20 nanometers. Its typical morphological features are figure 2 Shown.

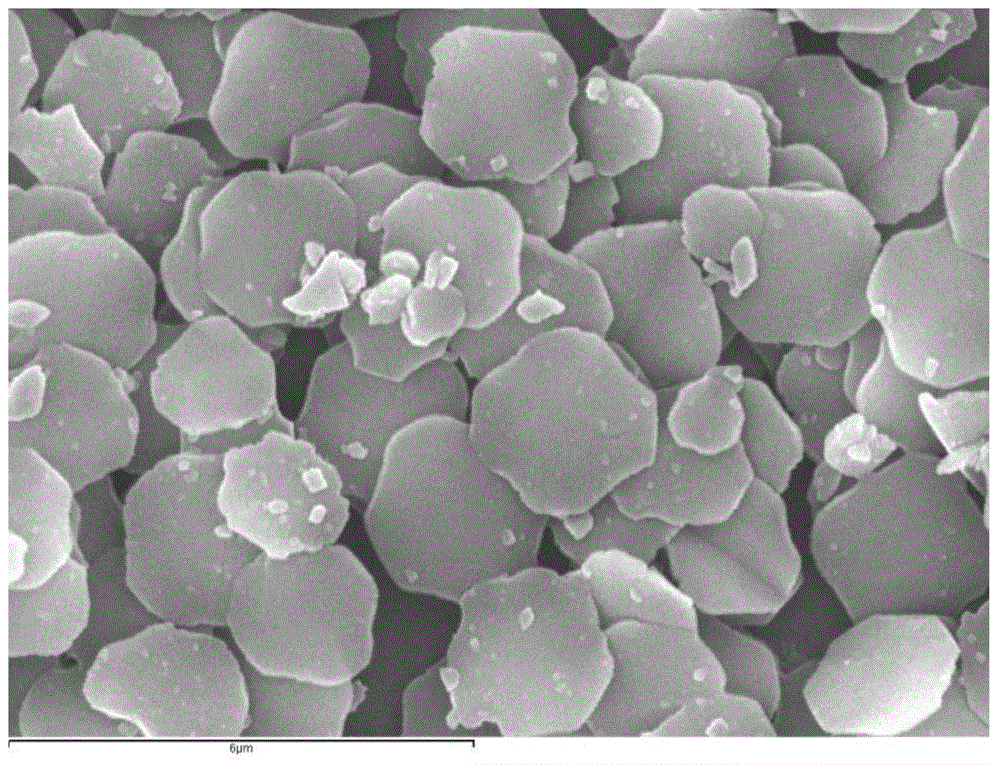

Embodiment 2

[0027] Take 90 liters of deionized water, add 10 grams of sodium citrate solid, stir to make it completely dissolved, then add 5 liters of 0.1M copper nitrate solution, stir and react for 50 minutes, and then add 5 liters of 0.1M concentration Sodium oxalate solution, stir and mix for 25 minutes, adjust the pH of the above mixed solution to 3.48 with 1M nitric acid or 1M sodium hydroxide solution, then let it stand for 14 hours at room temperature, then filter, collect the precipitated powder, and wash with water Remove the adhering impurity ions and dry the powder to obtain a flaky pearlescent copper oxalate powder material with good dispersion, small length and width, and thin thickness, with a plane diameter of 5 microns and a thickness of about 30 nanometers. Its typical morphological features are as image 3 Shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com