Composite anti-mud agent based on polycarboxylate-type pumping agent, anti-mud pumping agent and preparation method of anti-mud pumping agent

A technology of polycarboxylic acid series and anti-mud agent, which is applied in the field of concrete admixture, can solve the problems of poor mud resistance and great impact on concrete strength, etc., and achieve low cost, convenient large-scale promotion and use, and significant economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 is based on the combined anti-mud agent of polycarboxylate pumping agent

[0035] A kind of combined anti-mud agent based on polycarboxylate-based pumping agent in Example 1 of the present invention, based on the total mass of the polycarboxylic acid-based pumping agent, the combined anti-mud agent is composed of 0.1% to 0.6% % calcium nitrate, 0.05%-0.3% polyethylene glycol, 0.03%-0.1% β-dextrin and 0.2%-0.6% dimethyl diallyl ammonium chloride.

[0036] Among them, calcium nitrate can reduce the inhibitory effect of sulfate on the polycarboxylate superplasticizer molecules, and give full play to the water reducing performance of the polycarboxylate superplasticizer.

[0037] Polyethylene glycol can be adsorbed by clay instead of polycarboxylate superplasticizer, so as to ensure the concentration of effective polycarboxylate superplasticizer in concrete. Polyethylene glycol with a molecular weight of 1000-4000 can better play its role, preferably polyethyl...

Embodiment 2

[0045] Embodiment 2 anti-mud pumping agent

[0046] The anti-mud pumping agent of embodiment 2 of the present invention comprises polycarboxylate water reducer, air-entraining agent, retarder and water, wherein, also includes the combined anti-mud agent described in embodiment 1; Based on the total mass of the mud pumping agent, the mass percentage of the combined anti-mud agent is 0.38% to 1.6%.

[0047] Wherein, the polycarboxylate water reducer can be a conventional polycarboxylate water reducer with a solid content of 40%. The air-entraining agent adopts sodium lauryl sulfate (K 12 ), triterpene saponins, sodium dodecylbenzenesulfonate and other conventionally used synthetic anionic surfactant air-entraining agents get final product. The retarder can be sodium gluconate, white sugar or citric acid and other conventional conventional retarders.

[0048] The dosage of the polycarboxylate water reducer, air-entraining agent and setting retarder can be the existing ratio, tha...

Embodiment 3

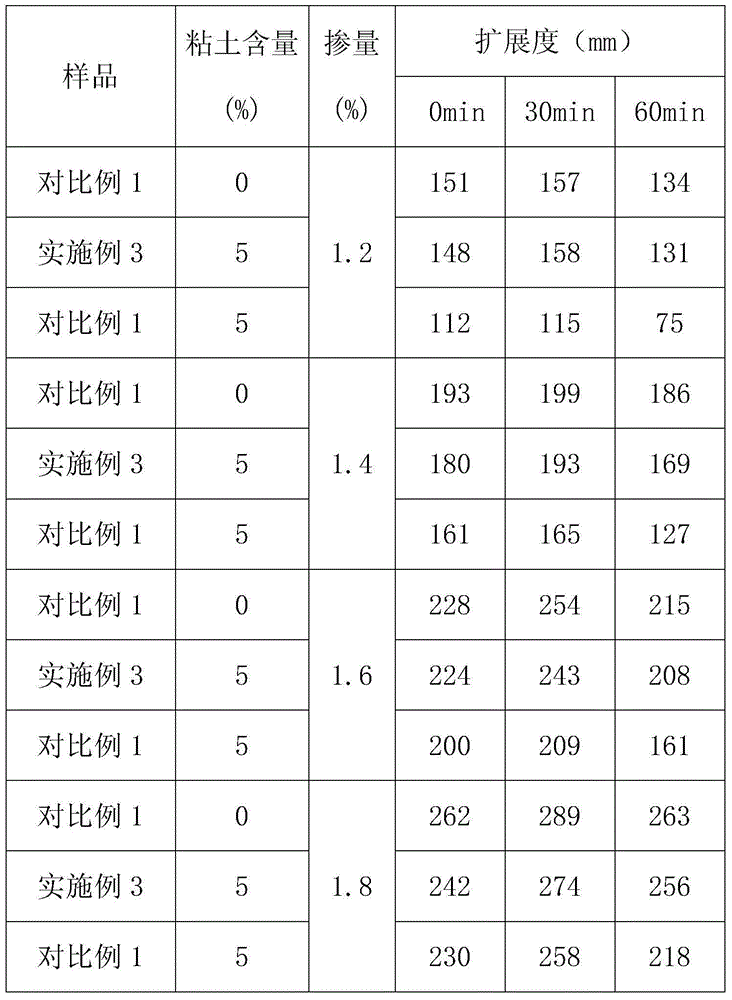

[0050] A kind of anti-mud pumping agent of the embodiment 3 of the present invention, by mass percentage, comprises the polycarboxylate superplasticizer (solid content is 40%) of 15%, the sodium lauryl sulfate air-entraining agent of 0.01%, 0.5% % sodium gluconate retarder, 0.4% calcium nitrate, 0.1% polyethylene glycol (molecular weight 1000-2000), 0.05% β-dextrin, 0.5% dimethyl diallyl ammonium chloride (mass concentration is 60% solution) and the water of balance. Wherein, the total mass percentage of the combined anti-mud agent is 1.05%.

[0051] The preparation method of the anti-mud pumping agent of present embodiment 3 is as follows:

[0052] Step 1. According to the components and content of the above-mentioned anti-mud pumping agent and combined anti-mud agent, weigh calcium nitrate, polyethylene glycol, β dextrin and dimethyl diallyl ammonium chloride, and polycarboxylic acid Water reducing agent, air entraining agent, retarder and water.

[0053] Step 2. Prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com