Method and device for restraining and preventing thermal runaway of lithium ion battery

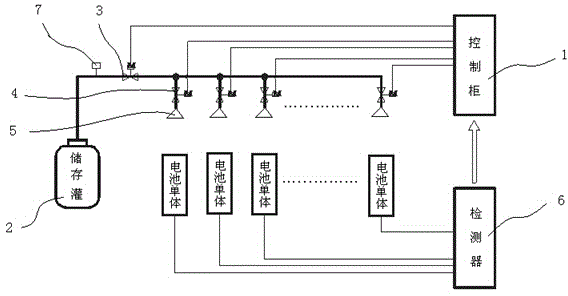

A lithium-ion battery, thermal runaway technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve problems such as unsatisfactory fire extinguishing efficiency, ozone layer destruction, etc., to suppress thermal runaway of batteries and expand spraying range , the effect of inhibiting exothermic side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: It is the basic embodiment of the method for suppressing and preventing thermal runaway of lithium-ion batteries in the present invention. The method is to use liquid inert gas to spray and refrigerate the faulty lithium-ion battery and extinguish the fire, and the steps include:

[0044] A. Select the timing of spraying: when the battery cell reaches a certain temperature, the spraying device is turned on;

[0045] B. Determine the spraying amount of the spraying gas: with the latent heat of vaporization of the liquid inert gas, the latent heat of vaporization of the liquid inert gas is 0.1 to 10 times the heat release of the thermal runaway of the battery cell;

[0046] C. Determine the spraying method: the spraying method is continuous spraying or intermittent spraying, which is selected according to the number of battery cells.

[0047] Said steps are implemented in order of A, spray timing, B, spray amount, and C spray mode, or in parallel, or in reve...

Embodiment 2

[0048] Example 2: It is a further embodiment of embodiment 1. The liquid inert gas is one of liquid nitrogen, liquid argon and liquid carbon dioxide, or two, or a combination of three. In the step A, the spraying device is turned on when the temperature of the battery cell reaches 60° C. to 140° C.

[0049] The spray volume of the liquid inert gas is in liters and is determined by the following formula:

[0050] h=0.1~10 Q / R (1)

[0051] In the formula: h is the liquid inert gas spray amount:

[0052] Q is the thermal runaway heat release of the battery cell;

[0053] R is the latent heat of vaporization per liter of liquid inert gas, which is a known data.

[0054] The thermal runaway heat release Q of the battery cell is determined by the following formula:

[0055] Q=m 1 q 1 + m 2 q 2 +…+ m n q n -----(2)

[0056] In the formula: q is the calorific value of the combustible materials that make up the lithium-ion battery;...

Embodiment 3

[0059] Example 3: is a preferred embodiment. The difference from Example 2 is that the liquid inert gas is selected as liquid nitrogen, and in the step A, the spraying device is turned on when the temperature of the battery cell reaches 120°C. In the B step, the spray amount of the spray gas is determined to be based on the latent heat of vaporization of the liquid inert gas, and the latent heat of vaporization of the liquid inert gas is 0.5 times of the thermal runaway heat release of the battery cell; the battery of the lithium ion battery The active material of the monomer is lithium iron phosphate. The battery cell capacity is 1.5AH. The shape of the battery cell is cylindrical. The liquid inert gas spraying method is continuous spraying once, and the spraying time to the battery cell is 5s. After the spraying, the whole device is turned off. After 10 minutes, the battery temperature is suppressed and tends to be stable, and the battery is intact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com