Braking simulation test device and method for km deep mine hoist disc brake

A disc brake and simulation test technology, which is applied in the testing of machines/structural components, measuring devices, testing of mechanical components, etc., can solve the problem of unsuitable braking performance and quality of mine hoist, failure to meet braking conditions simulation, failure Simulate braking performance quality testing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these examples are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention All modifications of the valence form fall within the scope defined by the appended claims of the present application.

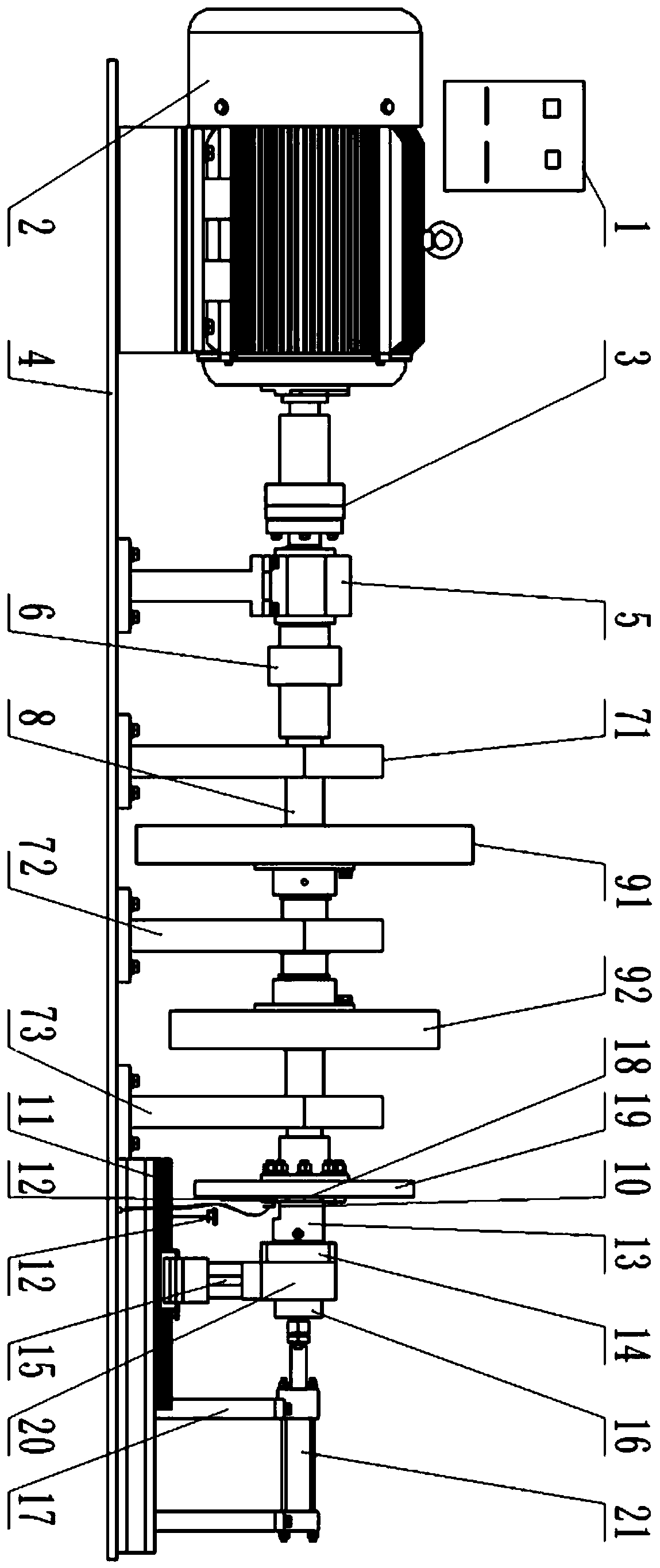

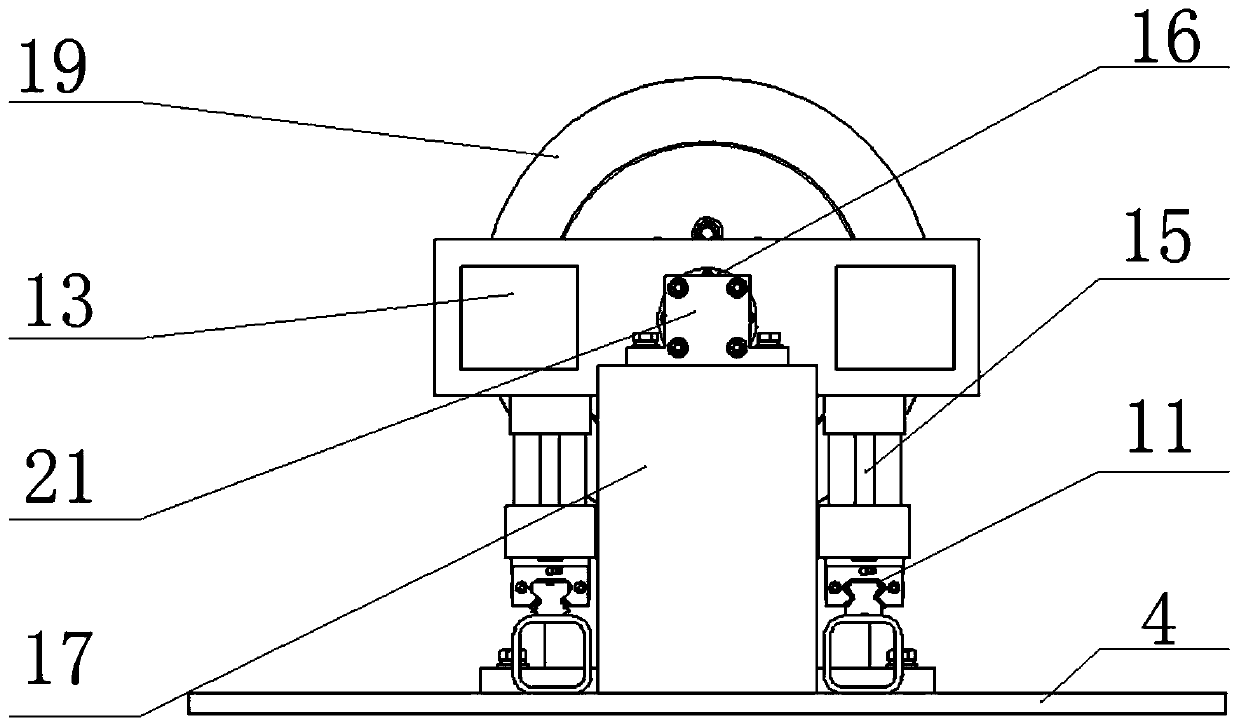

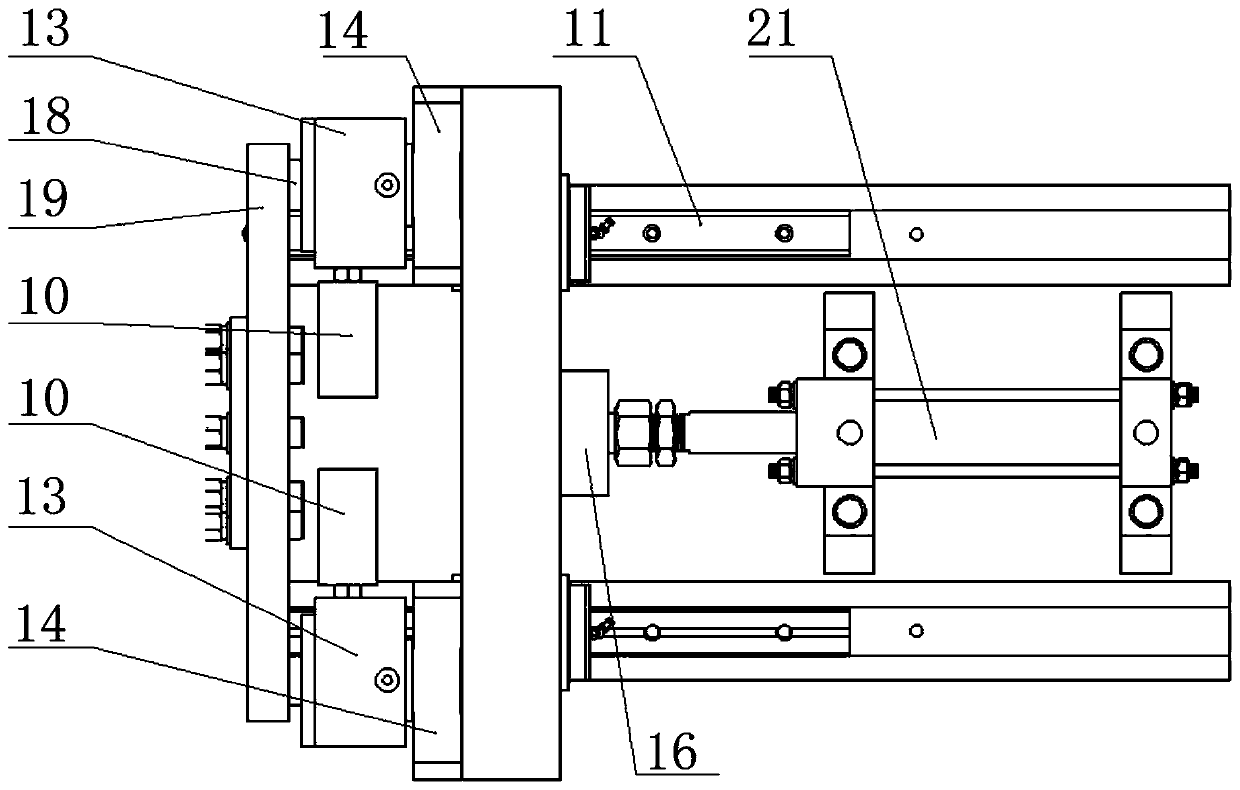

[0031] A brake simulation test device for a disc brake of a kilometer deep well hoist, such as figure 1 As shown, it includes a flywheel system, a braking system and a sensor monitoring system. The flywheel system includes a frequency converter 1, a motor 2, a jaw clutch 3, a gear coupling 6, a rotating shaft 8, and a flywheel assembly. The braking system includes a brake disc 19 , a brake shoe 18 , a brake shoe clamp 13 , a brake shoe clamp connecting plate 20 , a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com