Process method for preparing super-amphiphobic zinc surface

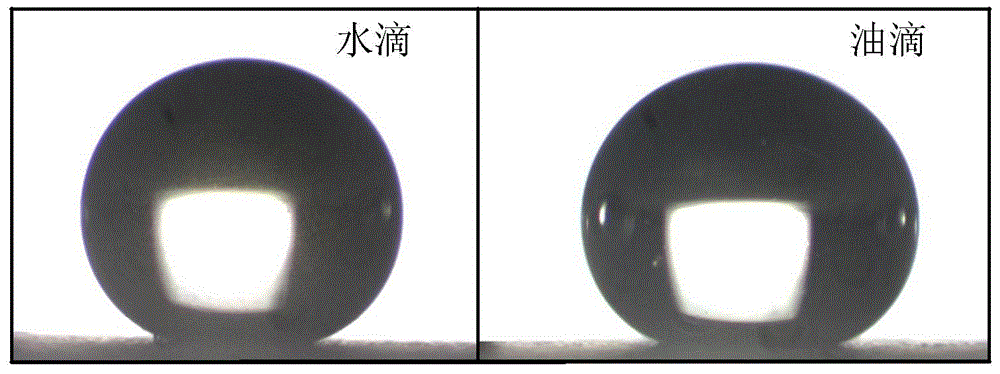

A process method, zinc surface technology, applied in metal material coating process, anodizing and other directions, can solve the problems of poor mechanical properties of superhydrophobic surfaces, solution toxicity, low processing efficiency, etc., and achieve excellent hydrophobic and oleophobic properties, resistance to The effect of enhanced corrosion performance and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) First, clean and degrease the zinc plate with a size of 40mm×30mm (the actual processing size is 30mm×30mm, and the excess part acts as a clamp and conduct electricity), and then perform mechanical polishing to remove the oxide layer on the zinc surface , and then use ultrasonic cleaning for 3 minutes, and dry it with a hair dryer for later use.

[0022] (2) Fix the cleaned zinc plate on the anode fixture and use it as an anode, and fix the graphite plate with a size of 40mm×30mm (the actual effective size is 30mm×30mm, and the excess part acts as a clamp and conduct electricity) on the cathode fixture And as a cathode, the distance between the cathode and anode is 30mm. After the cathode and anode are clamped, place it in a container filled with 0.05mol / L NaCl and 0.05mol / L NaNO 3 In the beaker of mixed electrolyte, connect the cathode and anode to the adjustable DC power supply.

[0023] (3) By controlling the current flowing through the anode to 1.5A through an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com