Non-pressure infiltration preparing method for Ti3AlC2/Fe-based composite material

A composite material and infiltration technology, applied in the field of pressureless infiltration preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

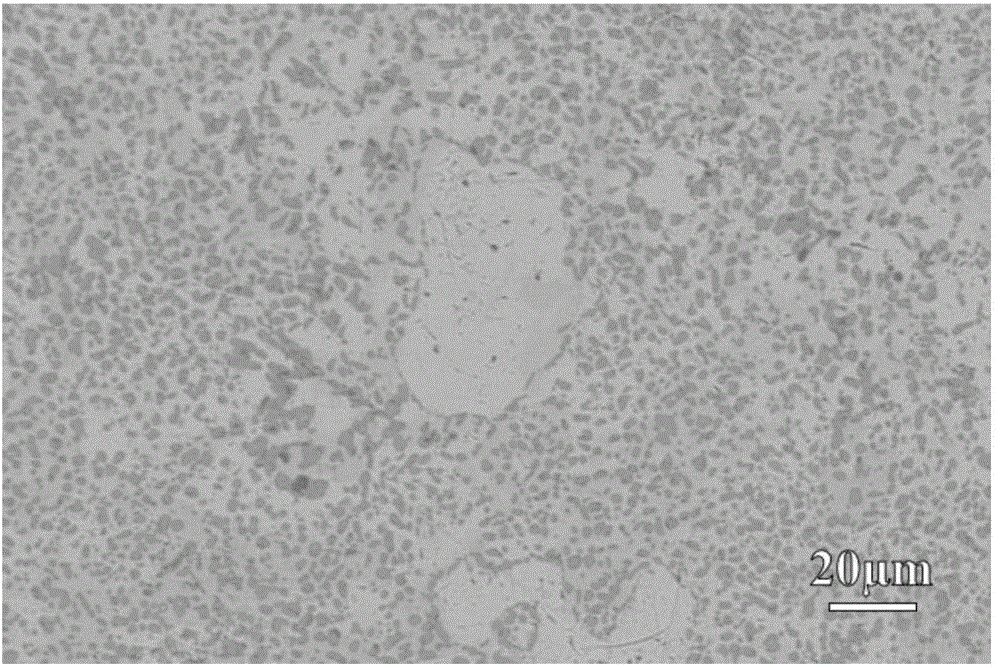

Embodiment approach 1

[0019] Put a certain mass of Fe90 alloy powder into an alumina crucible, put it into a vacuum sintering furnace, and under the protection of argon, raise the furnace temperature to 1300°C at a heating rate of 20°C / min, keep it for 30 minutes, and then heat it up at 15°C / min. The temperature is lowered at a rate of min, and an Fe-based alloy ingot is obtained after cooling. Porous Ti with a porosity of 20% 3 AlC 2 The prefabricated body is placed in an alumina crucible, and a pre-fired iron alloy ingot is placed above it, heated to 1300°C in a high-temperature furnace at a heating rate of 20°C / min, kept for 2 hours, and then cooled at a rate of 5°C / min Cool down to 800°C, then cool down at a rate of 20°C / min, and get Ti after cooling 3 AlC 2 / Fe-based composites.

[0020] The above bicontinuous phase Ti 3 AlC 2 / Fe-based composite material, processed into a cylinder with a diameter of 6mm and a length of 10mm, was loaded on a universal testing machine at a rate of 0.25mm / ...

Embodiment approach 2

[0022] Put a certain mass of Fe90 alloy powder into an alumina crucible, put it into a vacuum sintering furnace, and under the protection of argon, raise the furnace temperature to 1400°C at a heating rate of 40°C / min, keep it for 10 minutes, and then heat it up at a temperature of 10°C / min. The temperature is lowered at a rate of min, and an Fe-based alloy ingot is obtained after cooling. Porous Ti with a porosity of 54% 3 AlC 2 The prefabricated body is placed in an alumina crucible, and a pre-fired iron alloy ingot is placed above it, heated to 1400°C in a high-temperature furnace at a heating rate of 30°C / min, kept for 0.5h, and then heated at a rate of 10°C / min The cooling rate is reduced to 800°C, and then the temperature is lowered at a rate of 30°C / min. After cooling, Ti 3 AlC 2 / Fe-based composites.

[0023] The above bicontinuous phase Ti 3 AlC 2 / Fe-based composite material, processed into a cylinder with a diameter of 6mm and a length of 10mm, was loaded on a...

Embodiment approach 3

[0025] Put a certain mass of Fe90 alloy powder into an alumina crucible, put it into a vacuum sintering furnace, and under the protection of argon, raise the furnace temperature to 1250°C at a heating rate of 30°C / min, keep it for 20 minutes, and then heat it up at 10°C / min. The temperature is lowered at a rate of min, and an Fe-based alloy ingot is obtained after cooling. Porous Ti with a porosity of 68% 3 AlC 2The prefabricated body is placed in an alumina crucible, and a pre-fired ferroalloy ingot is placed above it, heated to 1300°C at a heating rate of 10°C / min in a high-temperature furnace, kept for 4 hours, and then cooled at a rate of 5°C / min Cool down to 800°C, then cool down at a rate of 10°C / min, and obtain Ti after cooling 3 AlC 2 / Fe-based composites.

[0026] The above bicontinuous phase Ti 3 AlC 2 / Fe-based composite material, processed into a cylinder with a diameter of 6mm and a length of 10mm, was loaded on a universal testing machine at a rate of 0.25m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com