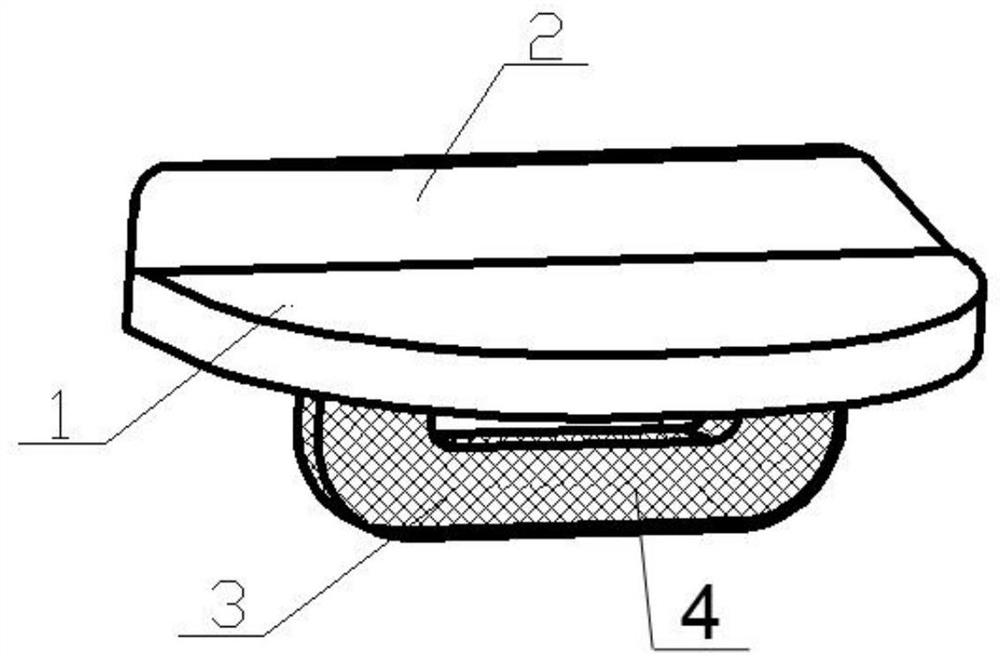

Zirconium-niobium alloy bone trabecula unicompartment tibial plateau prosthesis containing oxide layer and preparation method

A zirconium-niobium alloy and tibial plateau technology is applied in the field of zirconium-niobium alloy trabecular single-compartment tibial plateau prosthesis and preparation containing oxide layer, which can solve the problem of powder failure to obtain good fusion, uneven microstructure and mechanical properties. Good biocompatibility, low artifact, and enhanced compressive yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

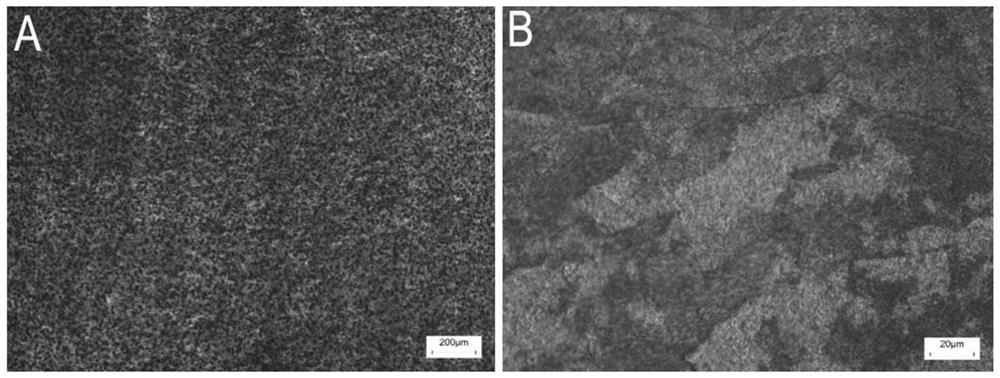

[0034] The preparation method of the unicompartmental tibial plateau prosthesis of zirconium-niobium alloy containing oxide layer comprises the following steps:

[0035] 1) Using zirconium-niobium alloy powder as raw material, the first intermediate product of the unicompartment tibial plateau prosthesis of zirconium-niobium alloy trabecular bone containing oxide layer was obtained through 3D printing, and the first intermediate product was put into a hot isostatic pressing furnace, Under the protection of helium, raise the temperature to 1250°C, place it at a constant temperature of 180MPa for 3 hours, drop to normal pressure, and take it out with the furnace cooling to below 200°C to obtain the second intermediate product;

[0036] 2) Place the second intermediate product in a programmed cooling box to cool down to -80°C at a rate of 1°C / min, place it at a constant temperature for 10 hours, and take it out of the programmed cooling box; place it in liquid nitrogen for another...

Embodiment 2

[0045] The preparation method of the unicompartmental tibial plateau prosthesis of zirconium-niobium alloy containing oxide layer comprises the following steps:

[0046] 1) Using zirconium-niobium alloy powder as raw material, the first intermediate product of the unicompartment tibial plateau prosthesis of zirconium-niobium alloy trabecular bone containing oxide layer was obtained through 3D printing, and the first intermediate product was put into a hot isostatic pressing furnace, Under the protection of helium, raise the temperature to 1325°C, place it at a constant temperature of 160MPa for 2 hours, drop to normal pressure, and take it out with the furnace cooling to below 200°C to obtain the second intermediate product;

[0047] 2) Place the second intermediate product in a programmed cooling box to cool down to -100°C at a rate of 1°C / min, place it at a constant temperature for 7 hours, and take it out of the programmed cooling box; place it in liquid nitrogen for another...

Embodiment 3

[0056] The preparation method of the unicompartmental tibial plateau prosthesis of zirconium-niobium alloy containing oxide layer comprises the following steps:

[0057] 1) Using zirconium-niobium alloy powder as raw material, the first intermediate product of the unicompartment tibial plateau prosthesis of zirconium-niobium alloy trabecular bone containing oxide layer was obtained through 3D printing, and the first intermediate product was put into a hot isostatic pressing furnace, Under the protection of argon, raise the temperature to 1400°C, place it at a constant temperature of 140MPa for 1 hour, drop to normal pressure, and take it out with the furnace cooling to below 200°C to obtain the second intermediate product;

[0058] 2) Place the second intermediate product in a programmed cooling box to cool down to -120°C at a rate of 1°C / min, place it at a constant temperature for 5 hours, and take it out of the programmed cooling box; place it in liquid nitrogen for another 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com