Method and device for preparing zirconia sizing nozzle with ZrO2-Al2O3 composite powder

A technology of zrO2-al2o3 and sizing nozzle, which is applied in the field of ZrO2-Al2O3 composite powder to prepare zirconia sizing nozzle and equipment, can solve the problems of high porosity, unreasonable gradation, blank particle shape and poor fluidity, etc. Achieve the effect of improving thermal shock stability and reducing the porosity of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

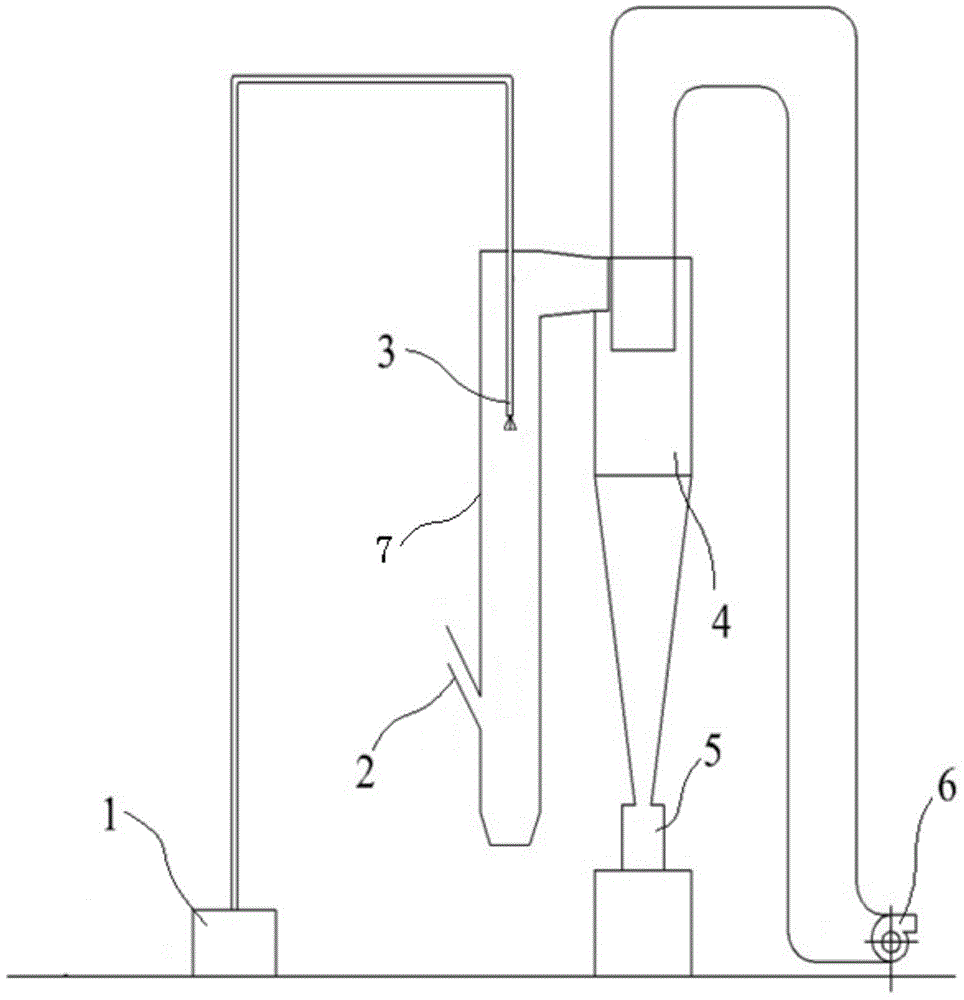

[0037] combine figure 1 and 2 , the suspended state circulating granulation equipment of this embodiment includes a pressure pump 1, a feed port 2, a nozzle 3, a cyclone 4, a collector 5, a fan 6 and a mixing cylinder 7, wherein:

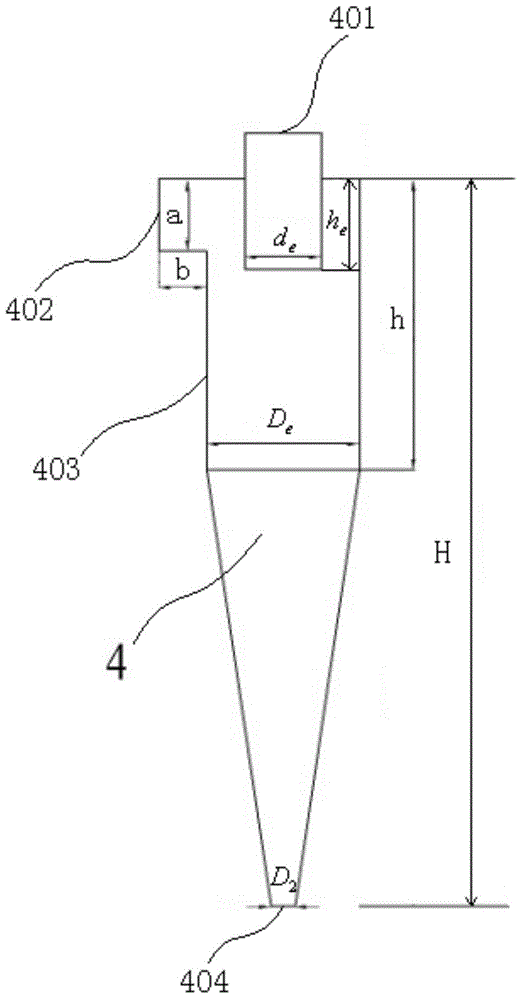

[0038] The cyclone 4 includes a core tube 401, an inlet 402, a cylinder 403 and a discharge port 404, the inlet 402 is located on the side of the cylinder 403, the core tube 401 communicates with the end of the cylinder 403, and the discharge port 404 is located on the side of the cylinder 403. the bottom of the body 403;

[0039] The pressure pump 1 communicates with the nozzle 3 to provide power for the material to be atomized to pass through the nozzle 3; the mixing cylinder 7 communicates with the inlet 402 of the cyclone 4, the nozzle 3 goes deep from the upper end of the mixing cylinder 7, and the feeding port 2 is set at the mixing At the bottom of the barrel 7, the screw feeder transports the raw materials from the feed port 2 to the mixin...

Embodiment 2

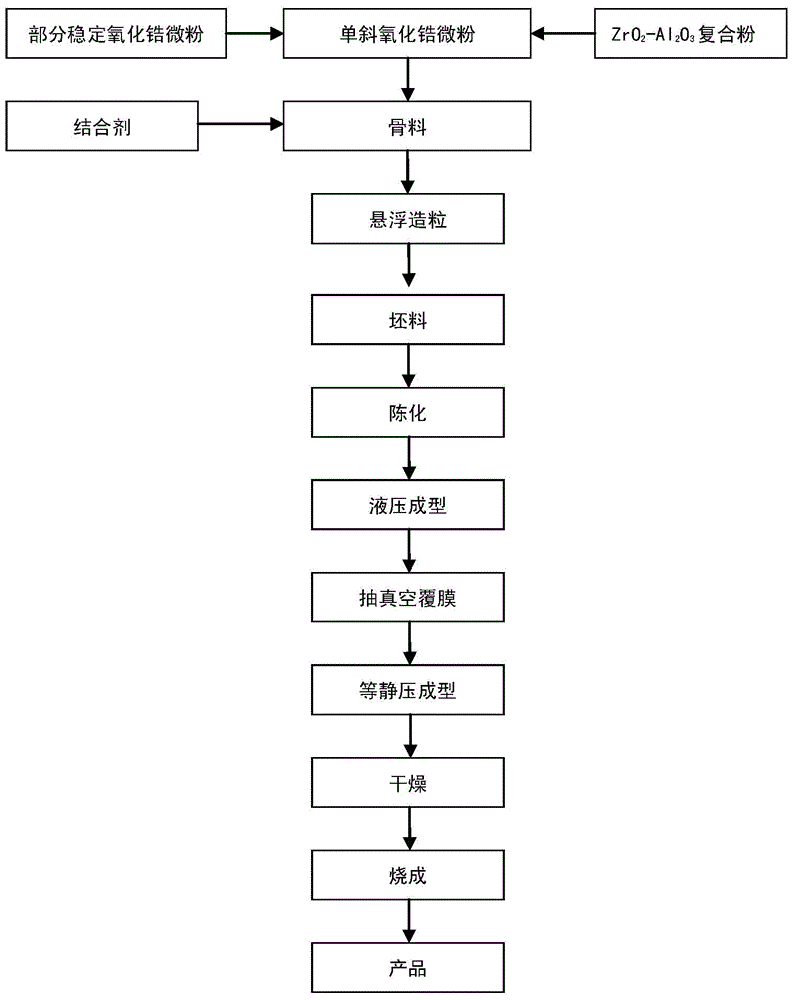

[0043] Step 1, the preparation of mixture:

[0044] 1) Raw materials include partially stabilized zirconia, monoclinic zirconia and Al 2 o 3 -ZrO 2 Composite powder, the chemical composition of partially stabilized zirconia is (wt%): ZrO 2 =95.02, HfO 2 =2.04, MgO=2.61, CaO=0.03, Al 2 o 3 =0.03, loss on ignition is 0.27, particle size is d 95 =1.0-5.0 μm, the chemical composition of monoclinic zirconia is (wt%): ZrO 2 +HfO 2 >98 and SiO 2 50 =1.0~2.0μm, d 95 2 o 3 -ZrO 2 The main chemical composition of the composite powder is (wt%): ZrO 2 +HfO 2 +Al 2 o 3 +Y 2 o 3 >99, Al 2 o 3 -ZrO 2 The particle size composition of the composite powder is: d 10 = 0.56 μm, d 50 = 1.12 μm, d 90 2 -Al 2 o 3 The dosage ratio of the composite powder is 47:50:3 and the proportion is accurate. Put the above materials into a polyurethane ball mill tank, use zirconia ceramic balls, and grind for 24 hours to ensure that the raw materials are fully mixed;

[0045] 2) ZrO 2 -...

Embodiment 3

[0056]The difference between this embodiment and embodiment 2 is: the ZrO in the step one 2 / Al 2 o 3 ZrO in composite powder 2 / Al 2 o 3 The ratio is adjusted to ZrO 2 / Al 2 o 3 =58 / 42; according to partially stabilized zirconia, monoclinic zirconia and ZrO 2 -Al 2 o 3 The dosage ratio of the composite powder is 46:50:4 and the proportion is accurate. Put the above materials into a polyurethane ball mill tank, use zirconia ceramic balls, and grind together for 24 hours to ensure that the raw materials are fully mixed; the ceramic type zirconia is obtained. Quality composite sizing nozzle composite inner layer, there is no burst during use, and the service life is 42h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Cold compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com