Sulfur-doped carbon nanowires, and three-dimensional sulfur-doped carbon nanowire network-silicon composite material and preparation method thereof

A technology of carbon nanowires and sulfur doping, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as limiting commercial applications, volume effects, and powdering of electrode materials. Achieve the effects of reducing charge transfer resistance, improving electrochemical performance, and inhibiting volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

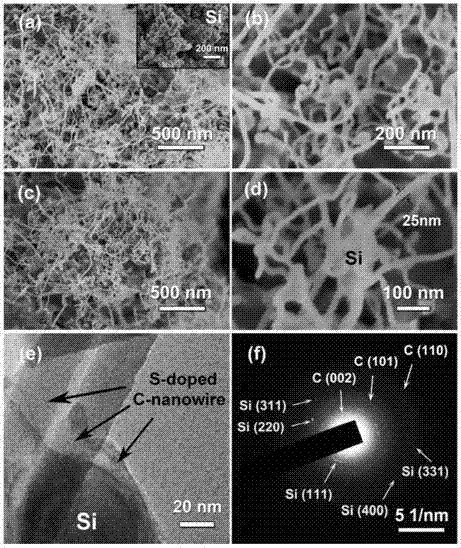

[0040] Embodiment 1: An embodiment of sulfur-doped carbon nanowire lithium-ion battery negative electrode material

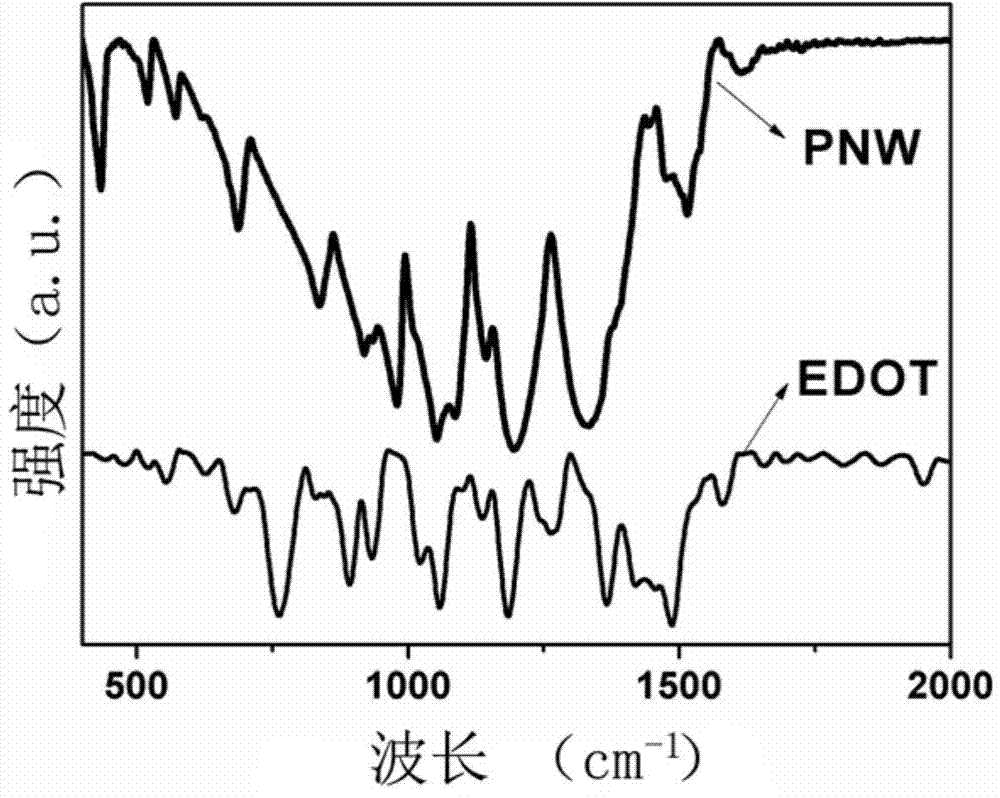

[0041] Weigh 0.183g of sodium lauryl sulfate and 0.009g of cetyltrimethylammonium bromide and dissolve them in 20ml of deionized water, and stir for 10 minutes to obtain a clear and transparent solution. Slowly drop 0.096g of 3,4-ethylenedioxythiophene under stirring, add 0.032g of FeCl 3 After obtaining a homogeneous solution. Place it in a 50°C oil bath with argon gas. Under magnetic stirring, the blue-black product poly-3,4-ethylenedioxythiophene was obtained after 10 hours of reaction. Suction filter the obtained product, use distilled water and absolute ethanol as washing solvents in turn, put the precipitate obtained after suction filtration in an oven at 60°C for 12h, cool to room temperature, and then calcinate and carbonize at 800°C under an argon protective atmosphere After 2 hours, the sulfur-doped carbon nanowire lithium ion battery negative elect...

Embodiment 2

[0042] Embodiment 2: An embodiment of sulfur-doped carbon nanowire lithium-ion battery negative electrode material

[0043] Weigh 0.27g of sodium lauryl sulfate and 0.018g of cetyltrimethylammonium bromide and dissolve them in 20ml of deionized water, and stir for 10 minutes to obtain a clear and transparent solution. Slowly drop 0.096g of 3,4-ethylenedioxythiophene under stirring, add 0.032g of FeCl 3 After obtaining a homogeneous solution. Place it in a 50°C oil bath with argon gas. Under magnetic stirring, the blue-black product poly-3,4-ethylenedioxythiophene was obtained after 10 hours of reaction. Suction filter the obtained product, use distilled water and absolute ethanol as washing solvents in turn, put the precipitate obtained after suction filtration in an oven at 60°C for 12h, cool to room temperature, and then calcinate and carbonize at 400°C under an argon protective atmosphere After 4 hours, the sulfur-doped carbon nanowire lithium ion battery negative electr...

Embodiment 3

[0044] Embodiment 3: An embodiment of sulfur-doped carbon nanowire lithium-ion battery negative electrode material

[0045] Weigh 0.458g of sodium lauryl sulfate and 0.022g of cetyltrimethylammonium bromide and dissolve them in 20ml of deionized water, and stir for 10 minutes to obtain a clear and transparent solution. Slowly drop 0.096g of 3,4-ethylenedioxythiophene under stirring, add 0.032g of FeCl 3 After obtaining a homogeneous solution. Place it in a 50°C oil bath with argon gas. Under magnetic stirring, the blue-black product poly-3,4-ethylenedioxythiophene was obtained after 10 hours of reaction. Suction filter the obtained product, use distilled water and absolute ethanol as washing solvents in turn, put the precipitate obtained after suction filtration into an oven at 60°C for 12h, cool to room temperature, and then calcinate and carbonize at 600°C under an argon protective atmosphere After 3 hours, the sulfur-doped carbon nanowire lithium ion battery negative ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com