Multi-core array integrated structure for LED light source

A technology of LED light source and LED chip, applied in the direction of light source, electric light source, light source fixation, etc., can solve the problems of difficult to achieve surface density, high luminous flux, etc., achieve compact structure and improved reliability, high brightness, and is conducive to organizing production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

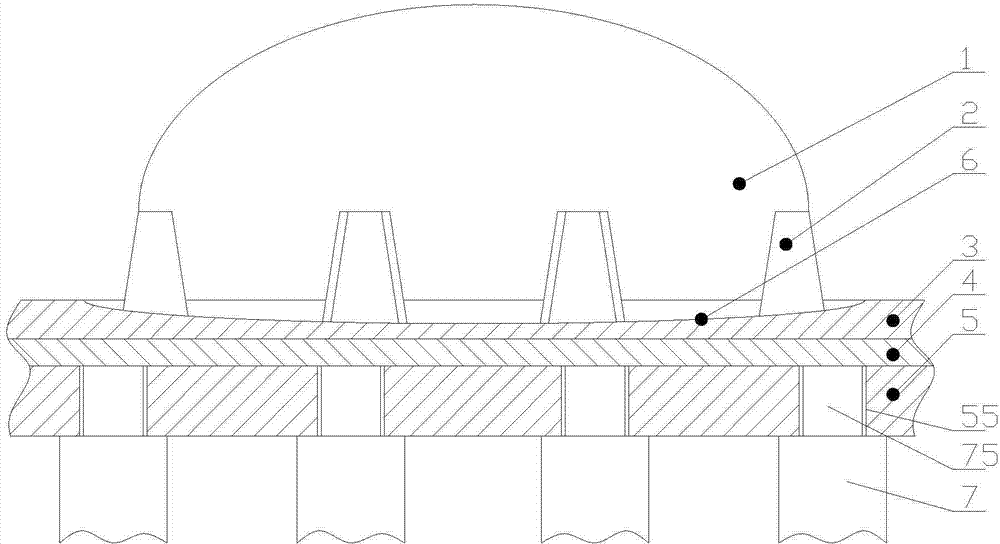

[0025] A multi-core array integrated structure for LED light source, which includes a substrate 5, the substrate 5 is provided with a printed circuit 3, the substrate 5 is an aluminum metal substrate 5, the printed circuit 3 and the substrate 5 are provided with a very thin spacer In the thermal layer 4, the upper end of the printed circuit 3 is recessed to form a cup-shaped groove 726. A number of LED chips 2 are welded in the cup-shaped groove 726, and the LED chips 2 are enclosed by a silicone resin layer 1. The printed circuit 3, the heat insulation layer 4 and the substrate 5 are glued together to form an integral heat dissipation structure 7. The number of LED chips 2 is 2N, where N is a natural number, so that the LED chips 2 can be connected in series and in parallel. Under special circumstances, the number of LED chips 2 can also be considered as an odd number. The multi-chip integrated structure can also be used as a unit, and several units form a light source array. ...

Embodiment 2

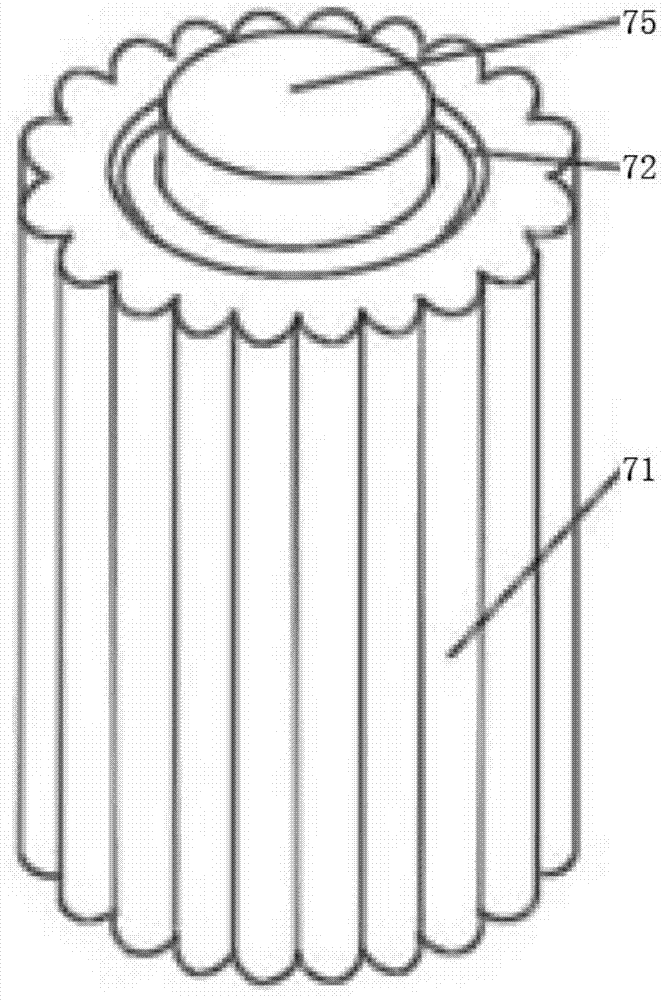

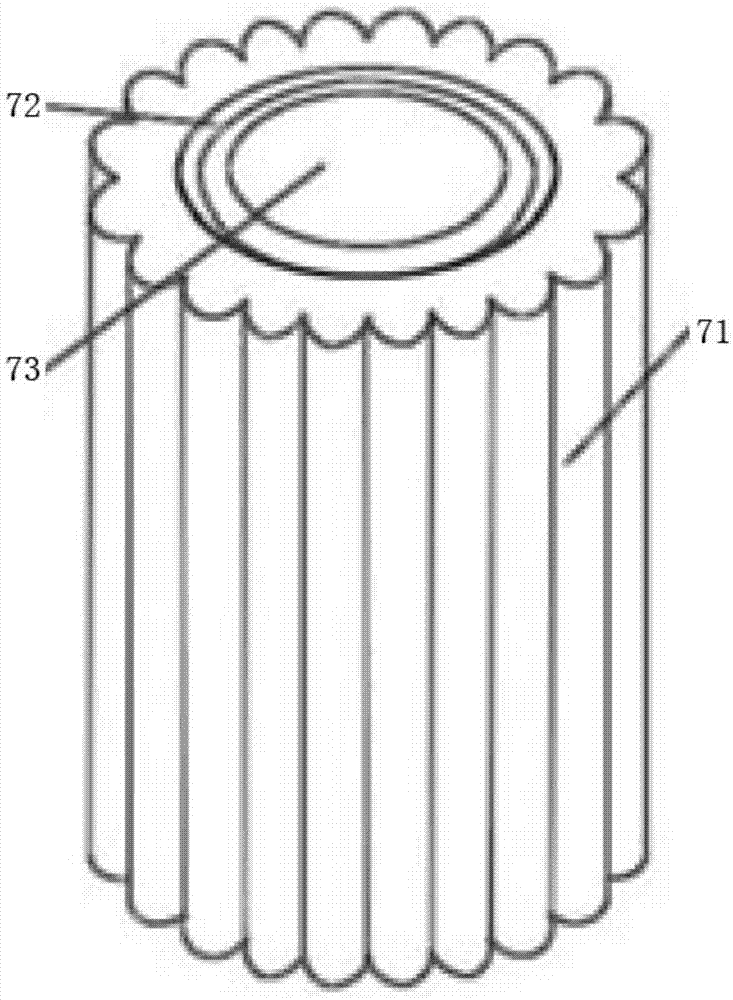

[0032] On the basis of the first embodiment, a plurality of copper foils 511 are arranged on the top and bottom surfaces of the substrate 5 at preset positions, and the copper foil 511 on the bottom surface of the substrate 5 is additionally provided with a tin layer 513 to prevent oxidation, and A plurality of LED chips 2 are arranged on the top surface of each copper foil 511 in one-to-one correspondence, so that each LED chip 2 and each copper foil 511 form an electrothermal connection. The bottom surface of the LED chip 2 is provided with an insulating layer 521 in contact with the copper foil 511, a heat dissipation via 512 is provided at the position of the copper foil 511 in contact with the LED chip 2 on the substrate 5, and the inner cylindrical surface of the heat dissipation via 512 is also A copper foil 511 is provided, and the copper foil 511 on the inner cylindrical surface of the heat dissipation via 512 forms an electrothermal connection with the copper foil 511 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com