Aerogel composite modified fire retardant and preparation method and application thereof

A compound flame retardant and compound modification technology, which is applied in the direction of textiles, papermaking, fiber treatment, etc., can solve the problems of high thermal conductivity, high water absorption, heavy weight, etc., and achieve high thermal conductivity, excellent heat insulation performance, safety The effect of reliable fire protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

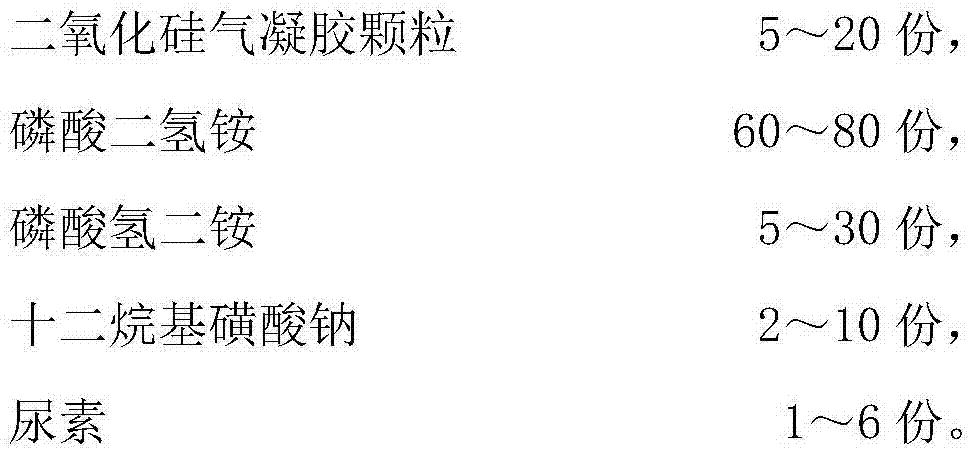

[0019] This embodiment relates to an airgel composite modified flame retardant, which is specifically prepared as follows:

[0020] The following raw materials were weighed in parts by weight: 5 parts of silica airgel particles, 60 parts of ammonium dihydrogen phosphate, 25 parts of diammonium hydrogen phosphate, 2 parts of sodium dodecylsulfonate and 1 part of urea.

[0021] Put all the above-mentioned raw materials into the blender in proportion, and stir evenly for 10 minutes before use.

[0022] The oxygen index is tested according to the provisions of the national standard GB50222 (code for fire protection design of building interior decoration), national standard GB5454 (determination of textile combustion performance, oxygen index method), national standard GB8624 (gradation method of building material combustion performance), and the flame retardant sample The performance parameters are as follows: Oxygen index: ≥34%.

Embodiment 2

[0024] This embodiment relates to an airgel composite modified flame retardant, which is specifically prepared as follows:

[0025] The following raw materials were weighed in parts by weight: 10 parts of silica airgel particles, 70 parts of ammonium dihydrogen phosphate, 5 parts of diammonium hydrogen phosphate, 6 parts of sodium dodecylsulfonate and 3 parts of urea.

[0026] Put all the above-mentioned raw materials into the blender in proportion, and stir evenly for 15 minutes before use.

[0027] The oxygen index is tested according to the provisions of the national standard GB50222 (code for fire protection design of building interior decoration), national standard GB5454 (determination of textile combustion performance, oxygen index method), national standard GB8624 (gradation method of building material combustion performance), and the flame retardant sample The performance parameters are as follows: Oxygen index: ≥36%.

Embodiment 3

[0029] This embodiment relates to an airgel composite modified flame retardant, which is specifically prepared as follows:

[0030] The following raw materials were weighed in parts by weight: 20 parts of silica airgel particles, 78 parts of ammonium dihydrogen phosphate, 30 parts of diammonium hydrogen phosphate, 10 parts of sodium dodecylsulfonate and 6 parts of urea.

[0031] Put all the above-mentioned raw materials into the blender in proportion, and stir evenly for 30 minutes before use.

[0032] The oxygen index is tested according to the provisions of the national standard GB50222 (code for fire protection design of building interior decoration), national standard GB5454 (determination of textile combustion performance, oxygen index method), national standard GB8624 (gradation method of building material combustion performance), and the flame retardant sample The performance parameters are as follows: Oxygen index: ≥38%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com