Graphene and preparation method thereof

A graphene and reaction technology, applied in the field of graphene and its preparation, can solve the problems of small number of graphene deposits, large catalyst size, low catalytic efficiency, etc., and achieve the effects of reducing energy consumption, simplifying the process, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

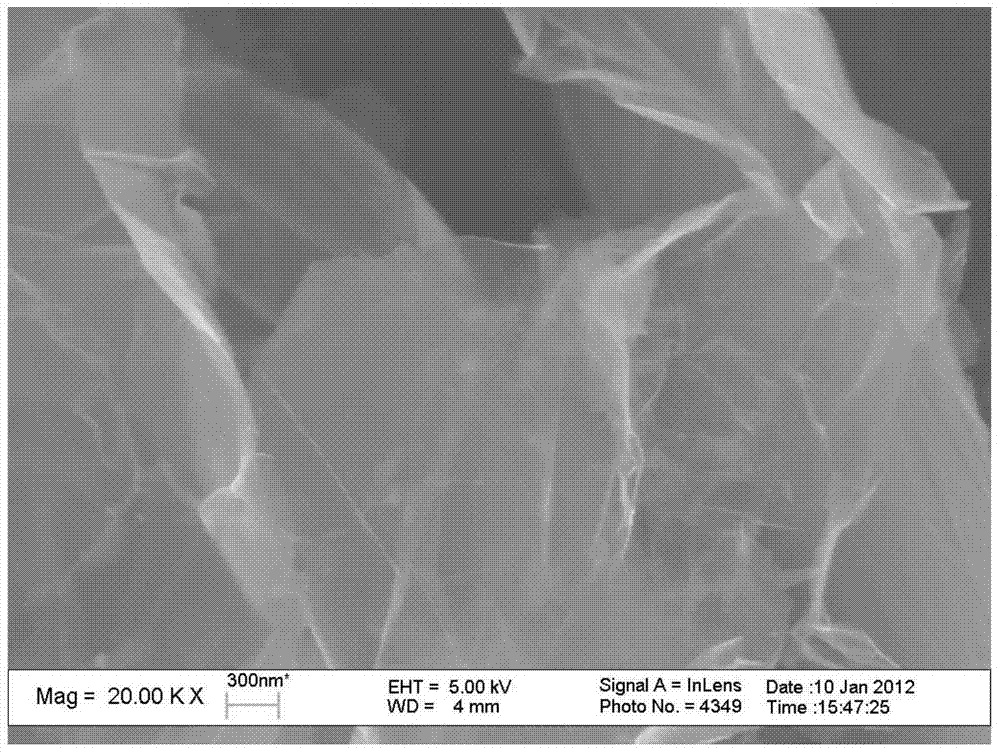

Image

Examples

preparation example Construction

[0059] See figure 1 , figure 1 Be the preparation method flowchart of graphene among the present invention, comprise the following steps:

[0060] S01, taking at least one of nano-metal powder and nano-metal oxide powder as a nano-catalyst loaded on the surface of the reaction deposition component;

[0061] S02. Put the reactive deposition component into the cavity of the chemical vapor deposition reactor and connect it to the inner wall of the cavity, the reactive deposition component is used to deposit the graphene generated by the reaction in a rotating state;

[0062] S03. Pass protective gas into the cavity of the chemical vapor deposition reactor, heat the reactive deposition part, and apply a driving force to the reactive deposition part at the same time to make the reactive deposition part rotate at a speed of 10-200r / min Rotating, during the rotation, the rotating surface of the reaction deposition component is perpendicular to the length direction of the reaction d...

Embodiment 1

[0077] A kind of preparation method of graphene, comprises the following steps:

[0078] (1) Preparation of nano-copper catalyst: Dissolve 4g of copper oxide in 20mL of dilute nitric acid, then add 2g of citric acid and 1g of oxalic acid, stir fully and drop in 1mL of hydrazine hydrate, and place the resulting mixed solution in In the muffle furnace, nitrogen gas is introduced, CO is introduced after the temperature is raised to 220°C, where V 氮气 :V CO =8:2, constant temperature 2h obtains the nano-metal copper powder that average particle diameter is 50nm, i.e. nano-copper catalyst;

[0079] The above-mentioned nano-copper powder is used as a nano-catalyst to be loaded on the surface of the reactive deposition component, wherein the load is adhered to the reactive deposition component through a high-temperature resistant epoxy resin, and the material of the reactive deposition component is a nickel-titanium superalloy;

[0080] (2) Put the reactive deposition component into...

Embodiment 2

[0087] A kind of preparation method of graphene, comprises the following steps:

[0088] (1) Add 10mL butyl titanate to 10mL deionized water, add 2g of tartaric acid after stirring, then drop in 2-3 drops of nitric acid to adjust pH2 powder;

[0089] Take the above nano-TiO 2 The powder is loaded on the surface of the reactive deposition component as a nano catalyst, wherein the loading is nano TiO 2 The catalyst is adhered to the reaction deposition part through aluminosilicate, and the material of the reaction deposition part is tungsten carbide;

[0090] (2) putting the reactive deposition component into the cavity of the chemical vapor deposition reactor and connecting it with the inner wall of the cavity, the reactive deposition component is used to deposit the graphene generated by the reaction in a rotating state;

[0091] (3) Feed nitrogen into the chamber of the chemical vapor deposition reactor, the flow rate of nitrogen is 200 sccm, heat the reaction deposition pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com