Method for preparing carbon nanodots based on chemical cutting

A technology of carbon nano-dots and chemical cutting, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science. It can solve the problems of cumbersome steps, high-temperature equipment, and high cost, and achieve simple process and multi-color The effect of fluorescence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 0.3g waste viscose-based carbon fiber (mechanical strength 0.7GPa), wash with acetone to remove surface sizing agent and other impurities, disperse in a mixture of 20ml nitric acid and 60ml concentrated sulfuric acid, and ultrasonicate at room temperature for 2h. Reflux at 80°C for 24h, the concentrated acid mixture is equivalent to chemical scissors to cut the sheet carbon structure into small-sized carbon nano-dots. After the reaction, cool to room temperature, dilute 10 times with deionized water, neutralize with an alkaline reactant such as sodium carbonate, filter with a 0.22 μm microporous filter head, and dialyze with a 2000 Da dialysis bag for 3 days to remove salt or other impurities. An aqueous solution containing yellow fluorescent carbon nano-dots was obtained, and the product size was about 10nm. The aqueous solution of carbon nano-dots was static for 8 weeks, no insoluble matter was precipitated, and the intensity of the fluorescence spectrum remained...

Embodiment 2

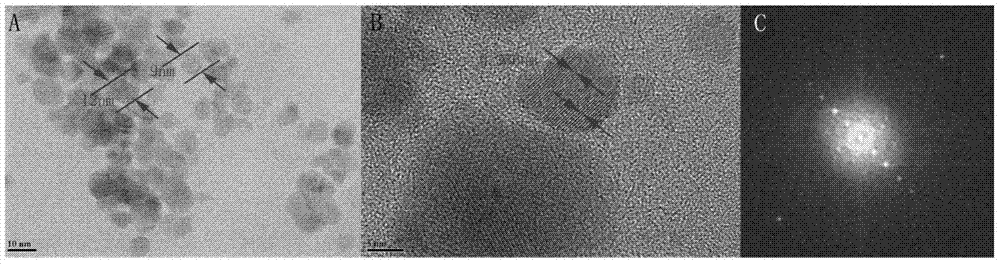

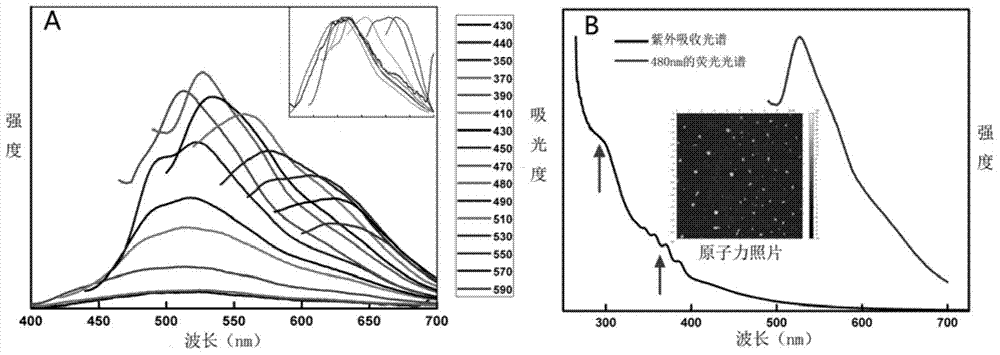

[0032] Weigh 0.3g waste viscose-based carbon fiber (mechanical strength 0.68GPa), wash with acetone to remove surface sizing agent and other impurities, disperse in a mixture of 20ml nitric acid and 60ml concentrated sulfuric acid, and ultrasonicate at room temperature for 2h. Reflux at 100°C for 24h, the concentrated acid mixture is equivalent to chemical scissors to cut the lamellar carbon structure into small-sized carbon nano-dots. After the reaction, cool to room temperature, dilute 10 times with deionized water, neutralize with an alkaline reactant such as sodium carbonate, filter with a 0.22 μm microporous filter head, and dialyze with a 2000 Da dialysis bag for 3 days to remove salt or other impurities. An aqueous solution containing green fluorescent carbon nano-dots is obtained, and the size of the product is 8-12 nm. Its transmission electron microscope pictures and spectra are attached figure 2 shown. The carbon nano-dot aqueous solution was static for 8 weeks, ...

Embodiment 3

[0038]Weigh 0.3g waste viscose-based carbon fiber (mechanical strength 0.68GPa), wash with acetone to remove surface sizing agent and other impurities, disperse in a mixture of 20ml nitric acid and 60ml concentrated sulfuric acid, and ultrasonicate at room temperature for 2h. Reflux at 120°C for 24h, the concentrated acid mixture is equivalent to chemical scissors to cut the lamellar carbon structure into small-sized carbon nano-dots. After the reaction, cool to room temperature, dilute 10 times with deionized water, neutralize with an alkaline reactant such as sodium carbonate, filter with a 0.22 μm microporous filter head, and dialyze with a 2000 Da dialysis bag for 3 days to remove salt or other impurities. An aqueous solution containing blue fluorescent carbon nanodots was obtained. The size of the product was 10nm, and the aqueous solution of carbon nanodots was static for 8 weeks, no insoluble matter was precipitated, and the intensity of the fluorescence spectrum remain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com