Milky white glass lamp tube for LEDs, milky white bulb for LEDs, and their manufacturing method

A glass lamp, milky white technology, applied in the field of lighting, can solve the problems of consuming optical resin or phosphor powder, increasing product material consumption, increasing personnel wages, etc. temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

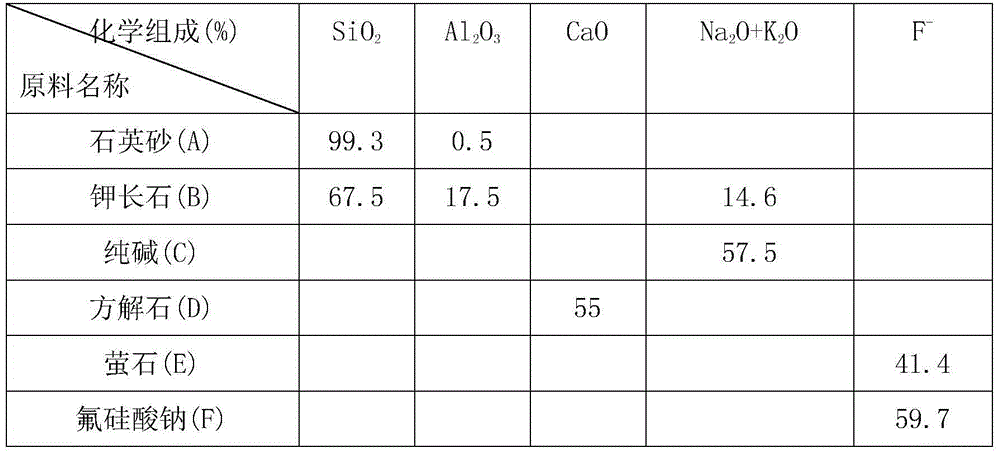

[0028] The formula of the present invention is made of quartz sand, potassium feldspar, soda ash, calcite, fluorite, sodium fluorosilicate, nitrate (potassium, sodium), containing CeO 2 The compound clarifying agent is formulated into batches according to different dosage ratios. The amount of various raw materials is obtained by solving the multivariate linear equation based on the chemical composition of the glass and the chemical composition of the raw materials. The chemical composition of batching in the present embodiment is: SiO 2 67.5%, Al 2 o 3 4.5%, CaO 5%, Na 2 O+K 2 O 18%, F - 5%.

[0029] A typical chemical composition of raw materials: as shown in Table 1.

[0030] According to the chemical composition of the glass and the chemical composition of the raw materials in Table 1, the formula is calculated, and the following equations are listed:

[0031] 0.993A+0.675B=67.5 (1)

[0032] 0.005A+0.175B=4.5 (2)

[0033] 0.55D = 5 (3)

[0034] 0.575C+0.146B=18 (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com