Preparation method for high-dielectric high temperature-resistant microwave dielectric composite material

A technology of microwave media and composite materials, which is applied in the field of composite material manufacturing, can solve the problems of low solid phase content of ceramics, achieve the effects of simple and environmentally friendly preparation process, reduce thermal expansion coefficient, and improve thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

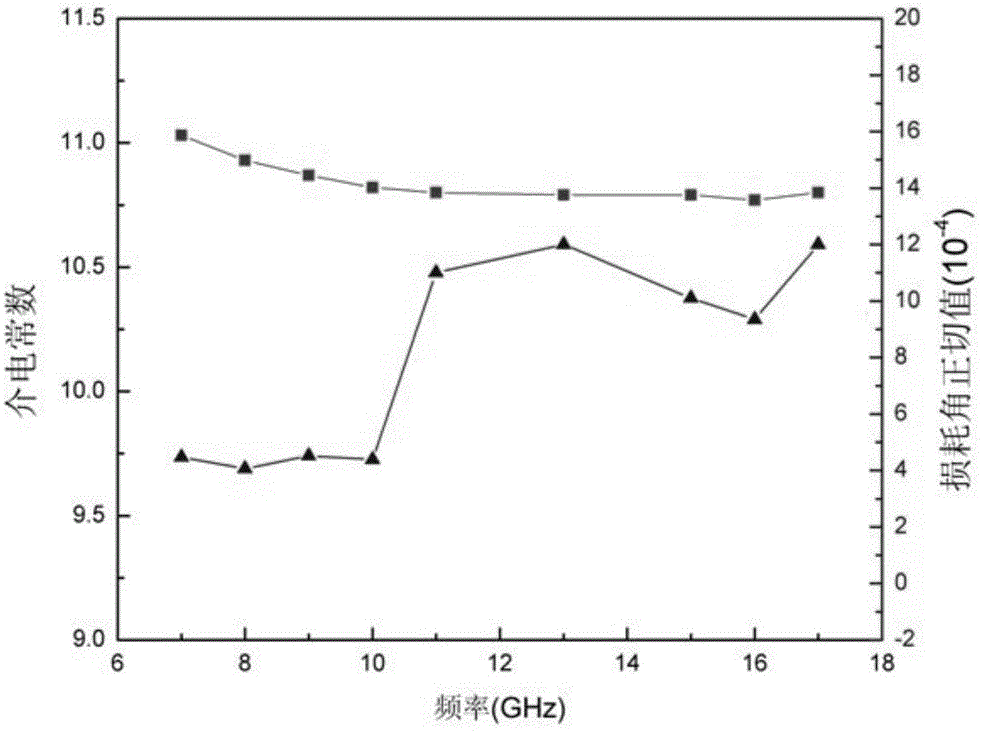

Image

Examples

specific Embodiment approach 1

[0019] Specific implementation mode 1: In this implementation mode, a method for preparing a high-dielectric and high-temperature-resistant microwave dielectric composite material is specifically carried out according to the following steps:

[0020] 1. Put the ceramic filler into the ethanol solution, add a silane coupling agent, adjust the pH to 8-10, stir it ultrasonically, put it in a water bath at a temperature of 50-60°C, keep it for 6-8 hours, and then perform centrifugal drying. Obtain ceramic powder;

[0021] 2. Dry the ceramic powder obtained in step 1 at 80°C for 24 hours, then mix it with resin powder, then add deionized water, mix evenly, then add zirconia ceramic balls and mix for 24 hours, put the mixed slurry Put it into an oven, control the temperature at 80°C for drying, and obtain a mixed powder of ceramics and resin;

[0022] 3. Put the mixed powder obtained in step 2 into a mold, carry out molding, then cool down naturally, demold and take out the pressed...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass ratio of the ceramic filler to the ethanol solution in step 1 is 1:1, and the volume ratio of ethanol to deionized water in the ethanol solution is 1:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment is different from Embodiment 1 in that the mass ratio of the ceramic filler to the silane coupling agent in step 1 is 1: (1.5%-5%). Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com