Heat transfer printing ink ribbon for metal material

A thermal transfer ribbon, metal material technology, applied in printing, ink ribbon, application, etc., can solve the problems of unclear and complete patterns and characters, poor scratch resistance, poor adhesion, etc., to achieve clear and complete printing patterns, The effect of good scratch resistance and good metal adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

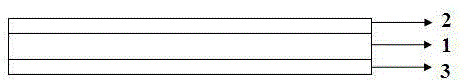

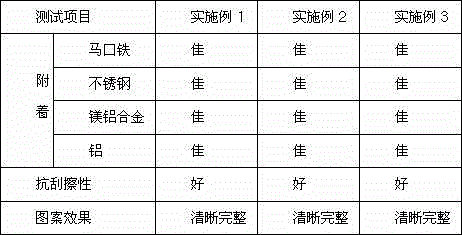

[0034] This embodiment provides a thermal transfer ribbon for metal materials, including a PET base film 1, a back coat 2 and a thermal transfer ink layer 3, and the weight fraction of the thermal transfer ink layer 3 is:

[0035] 7131-TK-50 25%

[0036] E-20 bisphenol A epoxy resin 18%

[0037] E-12 bisphenol A epoxy resin 8%

[0038] Tetrahydrophthalic anhydride 4%

[0039] Compound Wax 23.5%

[0040] PM-2 0.5%

[0041] Carbon black 10%

[0042] Auxiliary 1%

[0043] Solvent 10%

[0044] The thermoplastic acrylic resin is a type 7131-TK-50 acrylic resin with a Tg of 98°C, produced by Eternal Company. 7131-TK-50 has good adhesion to metal, and the printing pattern is clear and complete; it has high hardness at room temperature, which is also conducive to improving the scratch resistance of the transfer ink layer.

[0045] The E-20 bisphenol A epoxy resin has a softening point of 64-76° C., preferably DER671 from DOW, which can improve the adhesion and scratch resistan...

Embodiment 2

[0053] This embodiment provides a thermal transfer ribbon for metal materials, including a PET base film 1, a back coat 2 and a thermal transfer ink layer 3, and the weight fraction of the thermal transfer ink layer 3 is:

[0054] 7131-TK-50 20%

[0055] E-20 bisphenol A epoxy resin 20%

[0056] E-12 bisphenol A epoxy resin 6%

[0057] Tetrahydrophthalic anhydride 3%

[0058] Compound Wax 21%

[0059] PM-2 1%

[0060] Carbon black 11%

[0061] Auxiliary 2%

[0062] Solvent 16%

[0063]The thermoplastic acrylic resin is a type 7131-TK-50 acrylic resin with a Tg of 98°C, produced by Eternal Company. 7131-TK-50 has good adhesion to metal, and the printing pattern is clear and complete; it has high hardness at room temperature, which is also conducive to improving the scratch resistance of the transfer ink layer.

[0064] The E-20 bisphenol A epoxy resin has a softening point of 64-76° C., preferably DER671 from DOW, which can improve the adhesion and scratch resistance of...

Embodiment 3

[0072] This embodiment provides a thermal transfer ribbon for metal materials, including a PET base film 1, a back coat 2 and a thermal transfer ink layer 3, and the weight fraction of the thermal transfer ink layer 3 is:

[0073] 7131-TK-50 22%

[0074] E-20 bisphenol A epoxy resin 15%

[0075] E-12 bisphenol A epoxy resin 10%

[0076] Tetrahydrophthalic anhydride 3%

[0077] Compound Wax 23%

[0078] PM-2 1%

[0079] Carbon black 12%

[0080] Auxiliary 1%

[0081] Solvent 13%

[0082] The thermoplastic acrylic resin is a type 7131-TK-50 acrylic resin with a Tg of 98°C, produced by Eternal Company. 7131-TK-50 has good adhesion to metal, and the printing pattern is clear and complete; it has high hardness at room temperature, which is also conducive to improving the scratch resistance of the transfer ink layer.

[0083] The E-20 bisphenol A epoxy resin has a softening point of 64-76° C., preferably DER671 from DOW, which can improve the adhesion and scratch resistance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com