Method for preparing TiO2/g-C3N4 composite photocatalyst at low temperature

A C3N4, g-c3n4 technology, applied in the field of photocatalytic materials, can solve the problems of high photogenerated electron-hole recombination efficiency, low visible light catalytic activity, and high production cost, so as to improve the hydrogen production performance of photocatalytic water splitting and enhance the separation efficiency , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Take 5g of melamine and place it in a crucible, heat it in a muffle furnace with 10 o C / min heating rate increased to 550 o C was calcined for 4h, and g-C was obtained after cooling and grinding 3 N 4 Powder; add 1g of g-C 3 N 4 The matrix was added to a mixed solution of 25 mL hydrogen peroxide and ammonia water (the volume ratio of the two was 24:1), and the suspension was obtained after ultrasonic treatment for 30 minutes;

[0023] (2) Under an ice-water bath, measure 10 mL of 30 wt% H 2 o 2 and 0.8 mL of 28wt% concentrated NH 3 . h 2 O was placed in a round bottom flask; weighed 0.245 gH 2 TiO 3 Add it into the above-mentioned round bottom flask, stir for 30 minutes to obtain a yellow-green solution; mix this solution with the suspension obtained in step (1), and stir for 2 hours to obtain a suspension;

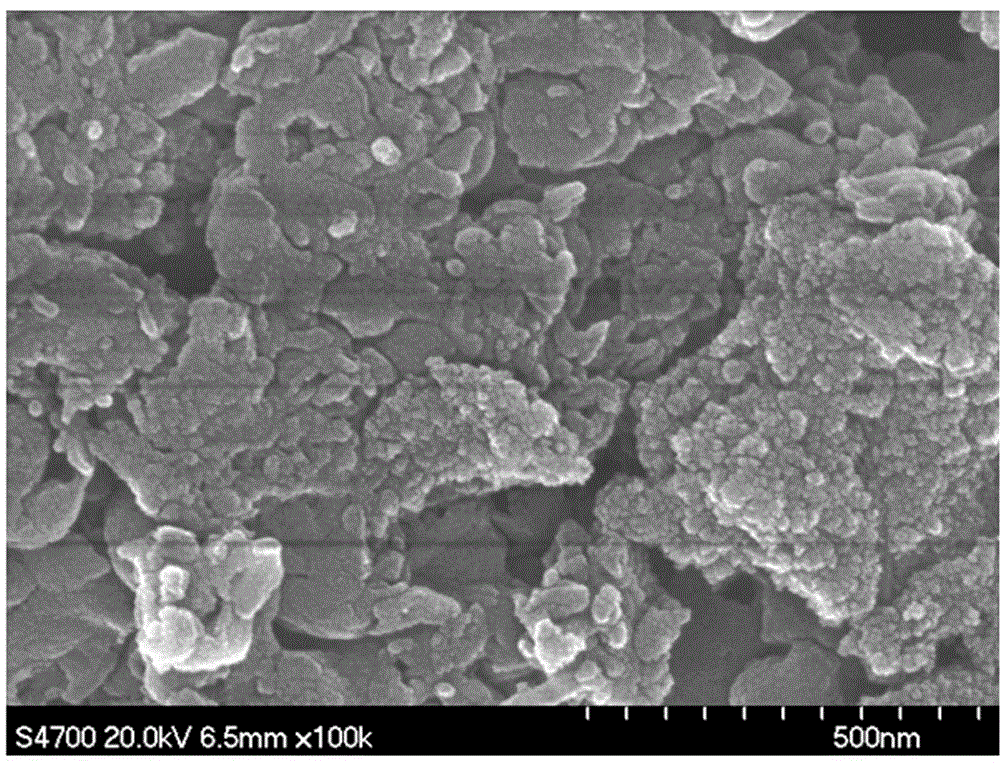

[0024] (3) Transfer the suspension obtained in step (2) into a stainless steel reaction kettle, react for 6 hours, and the reaction temperature is 1...

Embodiment 2

[0028] (1) Take 5g of dicyandiamide and place it in a crucible, o C / min heating rate increased to 550 o C was calcined for 4h, and g-C was obtained after cooling and grinding 3 N4 matrix, 1 g of g-C 3 N 4 The matrix was added to a mixed solution of 25 mL hydrogen peroxide and ammonia water (the volume ratio of the two was 24:1), and the suspension was obtained after ultrasonic treatment for 30 minutes;

[0029] (2) Other preparation methods are the same as in Example 1.

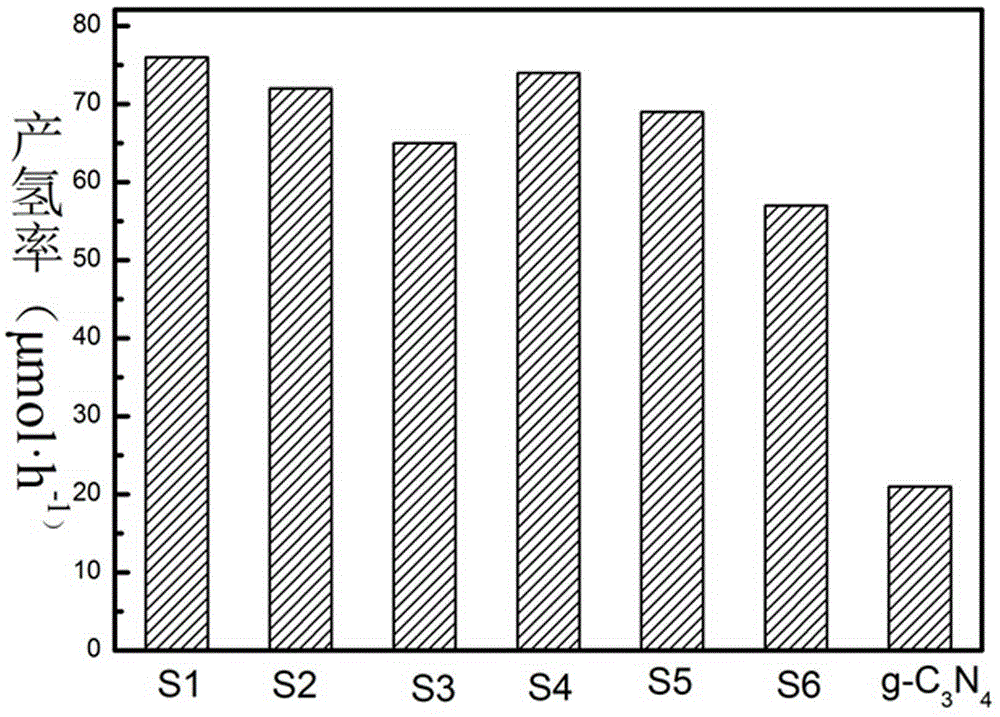

[0030] For the obtained finished TiO 2 / g -C 3 N 4 Composite photocatalysts were tested by X-ray diffraction (see image 3 ), it can be seen that the composite catalyst contains TiO with anatase configuration 2 and graphite phase C 3 N 4 Carry out visible light catalytic water splitting experiment according to the method of embodiment 1, the average hydrogen production rate of composite photocatalyst is 72 μ mol h -1 .

Embodiment 3

[0032] (1) g-C 3 N 4 Substrate preparation, method is with embodiment 1;

[0033] (2) Under ice water bath, measure 10mL, 30wt% H 2 o 2 and 0.5 mL28wt% concentrated ammonia water were placed in a round bottom flask, and 0.145g H was weighed 2 TiO 3 Add it into the above-mentioned round bottom flask, stir for 30 minutes to obtain a yellow-green solution; mix the yellow-green solution with the suspension obtained in step (1), and stir for 2 hours to obtain a suspension;

[0034] (3) Transfer the suspension obtained in step (2) into a stainless steel reaction kettle, react for 6 hours, and the reaction temperature is 160°C to obtain the product;

[0035] (4) Filter, wash, and dry the product obtained in step (3); the dried solid is calcined in a muffle furnace at 250°C to obtain the finished TiO 2 / g -C 3 N 4 Composite photocatalyst finished product.

[0036] For the obtained finished TiO 2 / g -C 3 N 4 Composite photocatalysts were tested by X-ray diffraction (see fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com