A kind of resin bond type diamond grinding pad and preparation method thereof

A diamond and bond technology, which is used in grinding tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problem that diamond grinding pads cannot be used for roughing and finishing at the same time, and is beneficial to product yield and improvement. The effect of deformation and demoulding to remove particle problems and eliminate void problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

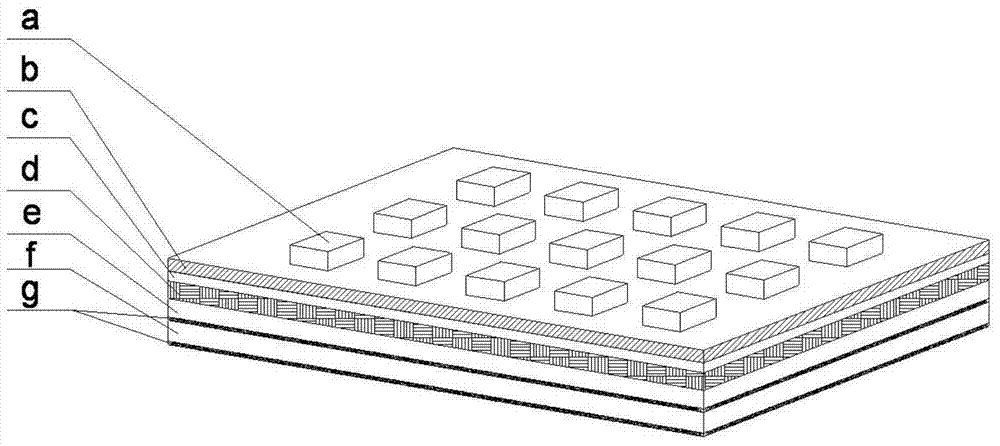

Image

Examples

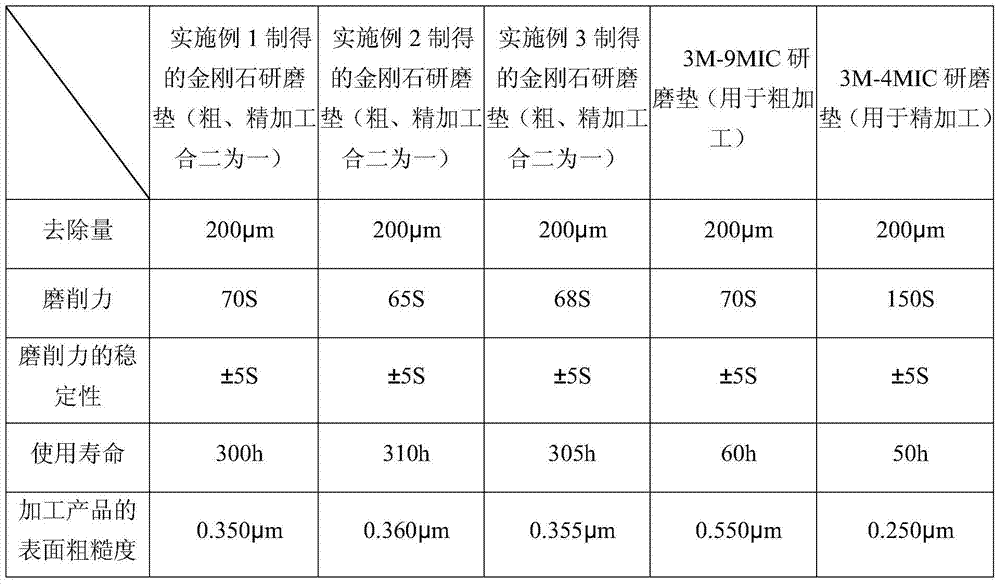

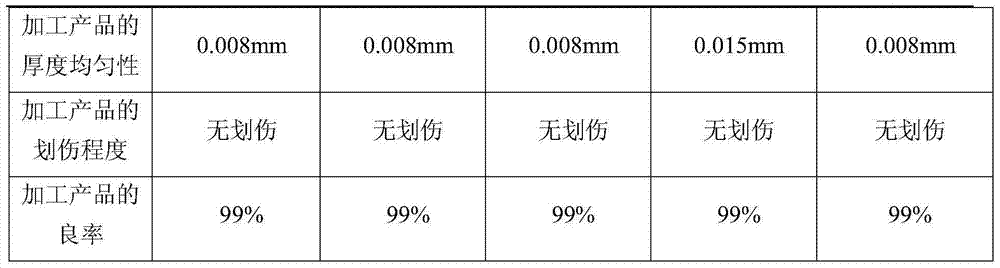

Embodiment 1

[0053] 1) Mixing: take each raw material by mass percentage, resin bond 35%, diamond 10%, wollastonite 50%, molybdenum disulfide 3%, fumed silica 2%, wherein E material needs to be sieved, wherein , The average particle size of diamond is 30μm; the average particle size of wollastonite is 30μm; the average particle size of molybdenum disulfide is 10μm; the average particle size of fumed silica is 100nm. Pour the weighed raw materials into the material cup at one time, and use a vacuum planetary mixer to stir evenly for 6 minutes, and the speed of the mixer is 400rpm / 2min, 500rpm / 2min, 600rpm / 2min.

[0054] The resin binder includes 59% epoxy resin, 40% acid anhydride curing agent and 1% accelerator.

[0055] 2) Pouring: Fill the uniformly mixed raw materials obtained in 1) into the square groove at the bottom of the silicone rubber mold of the abrasive pad, and after the surface is smoothed, put it into a vacuum defoaming machine for 3 times, 30 minutes each time, The vacuum ...

Embodiment 2

[0062] 1) Mixing: take each raw material by mass percentage, resin bond 47%, diamond 15%, wollastonite 34%, molybdenum disulfide 3%, fumed silica 1%, wherein E material needs to be sieved, wherein , The average particle size of diamond is 30μm; the average particle size of wollastonite is 30μm; the average particle size of molybdenum disulfide is 10μm; the average particle size of fumed silica is 100nm. Pour the weighed raw materials into the material cup at one time, and use a vacuum planetary mixer to stir evenly for 6 minutes, and the speed of the mixer is 400rpm / 4min, 500rpm / 4min, 600rpm / 4min.

[0063] The resin binder includes 44% epoxy resin, 55% acid anhydride curing agent and 1% accelerator.

[0064] 2) Pouring: Fill the uniformly mixed raw materials obtained in 1) into the square groove at the bottom of the silicone rubber mold of the abrasive pad, and after the surface is smoothed, put it into a vacuum defoaming machine for 3 times, 30 minutes each time, The vacuum ...

Embodiment 3

[0071] 1) Mixing: take each raw material by mass percentage, resin bond 47%, diamond 5%, wollastonite 39%, molybdenum disulfide 8%, fumed silica 1%, wherein E material needs to be sieved, wherein , The average particle size of diamond is 20μm; the average particle size of wollastonite is 15μm; the average particle size of molybdenum disulfide is 10μm; the average particle size of fumed silica is 100nm. Pour the weighed raw materials into the material cup at one time, and use a vacuum planetary mixer to stir evenly for 6 minutes, and the speed of the mixer is 400rpm / 2min, 500rpm / 3min, 600rpm / 4min.

[0072] The resin binder includes 50% epoxy resin, 49% acid anhydride curing agent and 1% accelerator.

[0073] 2) Pouring: Fill the uniformly mixed raw materials obtained in 1) into the square groove at the bottom of the silicone rubber mold of the abrasive pad, and after the surface is smoothed, put it into a vacuum defoaming machine for 3 times, 30 minutes each time, The vacuum v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com