Recovery Process of Medium and Low Grade Associated Copper in Silver Mine

A low-grade, silver ore technology, applied in solid separation, flotation, etc., can solve the problems of calcium accumulation in pipelines, low gold and silver cyanide leaching rate, and large cyanide consumption, so as to improve the grade and recovery rate, Effect of increasing cyanide leaching rate and reducing copper content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

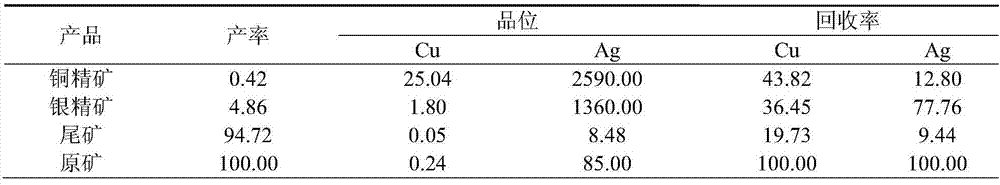

[0016] Aiming at a complex low-grade copper-containing silver ore containing about 0.2% copper, about 0.1% lead and zinc, and about 80g / t silver, the technology of the present invention is used to obtain a part of qualified copper concentrate quickly and copper floating The beneficiation test of the tailings and then flotation and silver beneficiation, the test conditions are: crush the ore, the grinding fineness -0.074mm accounts for about 70%, add water to adjust the slurry, and the pH value of the coarse beneficiation slurry with priority for rapid copper separation is about 9, The pulp concentration is about 35%; use ethyl butyl formate and Z-200 (ethylthiocarbamate) to prepare collector QP-03 at a mass ratio of 4:1; add collector and foaming agent to the pulp to The foaming agent is 2# oil, the amount of collector QP-03 is 7g / t, and the amount of foaming agent is about 7g / t; one roughing, one sweeping, and finally two refining, the roughing time is 30s. The test results a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com