Novel technology for improving gold and silver cyanidation recovery rates by arsenic-containing acid leaching residue pre-treatment

A technology of pretreatment and leaching slag, which is applied in the direction of improving process efficiency, etc., can solve the problems of stricter arsenic requirements and lower leaching rate, and achieve significant economic benefits, low cost, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

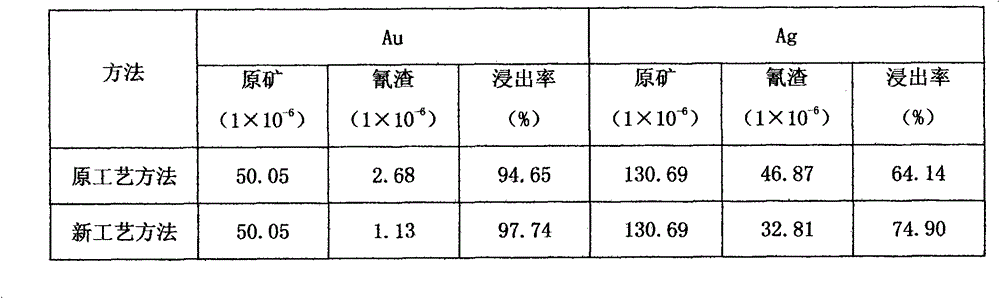

[0016] The arsenic-containing acid leaching residue of a gold smelter was selected, its chemical composition: Au 50.05 (1×10 -6 ), Ag 130.69 (1×10 -6 ), Cu 0.21%, Pb 1.29%, Zn 1.10%, As 0.47%, Fe 28.5%, S 0.50%.

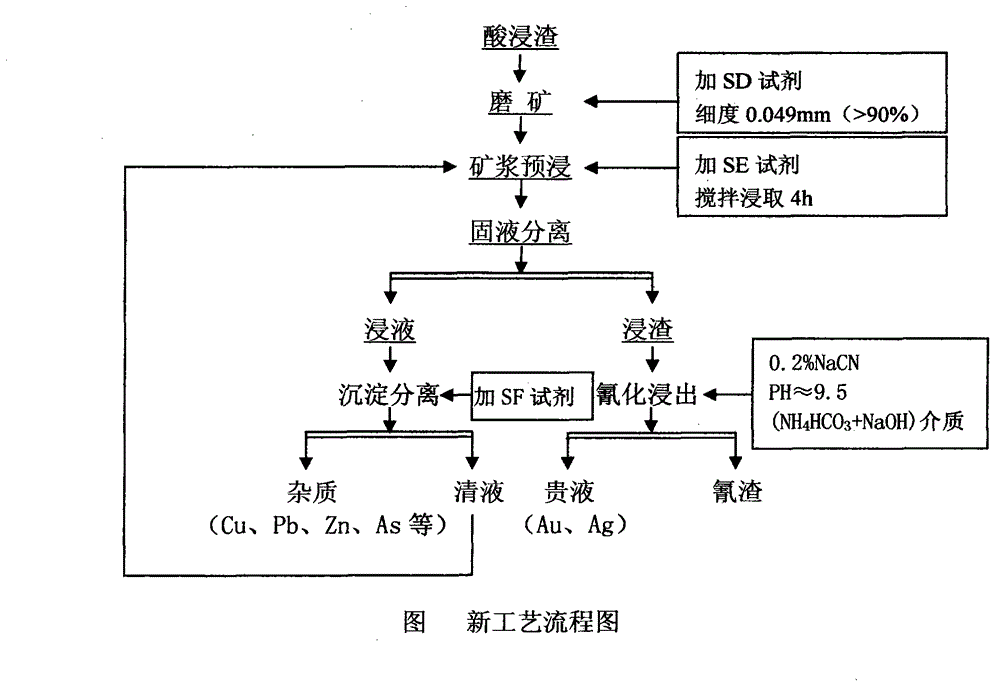

[0017] 1 Add mixed reagent SD for regrinding

[0018] Weigh 1 kg of arsenic-containing acid leaching residue, add 30 g of mixed reagent SD, add water to adjust the slurry, the concentration is 45%, and grind on a ball mill for 20 minutes, the fineness of the ore sample reaches 0.043 mm and is greater than 90%.

[0019] 2 plus mixed reagent SE pre-dip impurity removal

[0020] Add mixed reagent SE to the regrinded pulp, stir and leach in the pre-soak tank for 4 hours, filter and wash the pulp, leaching gold and silver from the filter residue by cyanide method, add SF reagent to the filtrate to precipitate Cu, Pb, Zn, As and other metal ions, the supernatant is returned for reuse.

[0021] 3 Cyanide leaching of gold and silver

[0022] Put the filter residue in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com