A method for decarburization of carbon-containing gold ore by raising material, adjusting wind, supplementing heat, roasting

A technology of roasting and heating, which is applied in the field of carbon-bearing gold ore raising materials, adjusting air, heating, roasting and decarburization, which can solve the problem that it is difficult to ensure that the gold ore materials are in full contact with the airflow, the temperature and atmosphere in the kiln cannot be effectively adjusted, and the roasting process effect Unsatisfactory and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The method for decarburizing the carbon-containing gold ore by raising material, regulating air, supplementing heat, roasting, and decarburization comprises the following steps:

[0039] (1) Crush the carbon-containing gold ore to a particle size of ≤ 8mm to obtain the material to be roasted; for the dense carbon-containing gold ore, it must be ground into powder and then made into granular ore;

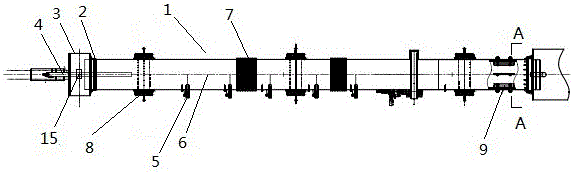

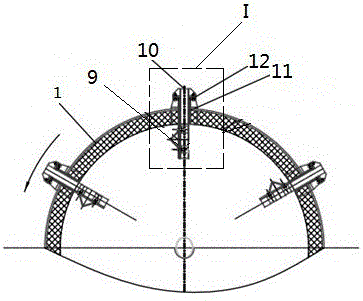

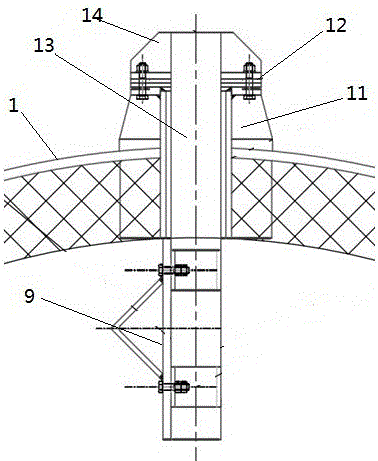

[0040] (2) The material is added to the roasting rotary kiln for roasting after being metered by the metering feeder; the rotational speed of the roasting rotary kiln is controlled by a frequency conversion speed regulating motor to control the residence time of the material in the kiln. If the residence time needs to be shortened, increase the speed of the kiln to accelerate the downward movement of the material in the kiln; otherwise, reduce the rotational speed of the kiln to slow down the downward movement of the material in the kiln;

[0041] The roasting rotary kiln is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com