Conductive paste composition

A technology of conductivity and composition, applied in conductive coatings, circuits, capacitors, etc., to achieve the effect of inhibiting the erosiveness of the chip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0087] [Preparation of conductive paste composition]

[0088] Prepare the conductive paste composition (sample 1-8) according to the following procedure

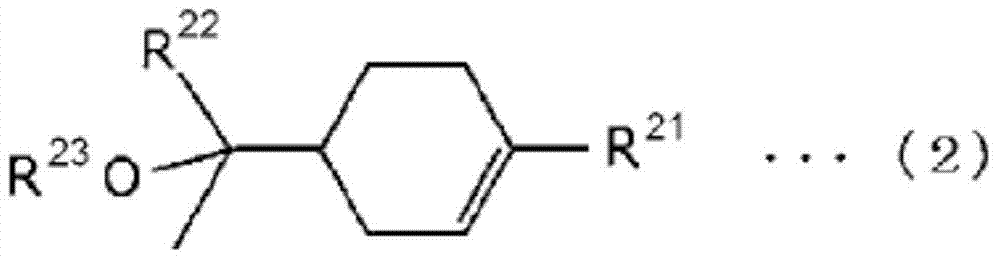

[0089] That is, first, ethylcellulose (EC) as a binder and isobornyl acetate (IBA) as a main solvent were mixed and stirred at 70° C. for 24 hours to prepare a carrier. Next, conductive powder, additives, and auxiliary solvents were added to the carrier, and sufficiently kneaded by a three-roll mill to obtain conductive paste compositions (samples 1 to 8). It should be noted that, as an auxiliary solvent, the solvents of the combinations shown in the following Table 2 are mixed so that the main solvent: auxiliary solvent is 70:30 in terms of mass ratio, and the viscosity of the conductive paste composition is 0.1 to 3 Pa·s In the range. In addition, the Hansen solubility parameter (HSP) of each auxiliary solvent is shown in Table 2 below.

[0090] In addition, as an additive, barium titanate (BaTiO 3 ) powder. The condu...

Embodiment approach 2

[0112] Both the main solvent and the auxiliary solvent of the organic solvent were changed to prepare a conductive paste composition (sample 9). That is, as shown in the following Table 3, the main solvent uses (c) dihydroterpineyl propionate with a smaller HSP to replace (d) isobornyl acetate, and the auxiliary solvent uses a solvent with HSP slightly larger than (d) isobornyl acetate. (e) Dihydroterpineol, the latter is carried out similarly to the case of the said Embodiment 1, and the electroconductive paste composition is prepared.

[0113] The conductive paste composition of Sample 9 and the conductive paste composition of Sample 2 prepared in Embodiment 1 were applied to the surface of the same ceramic green sheet as in Embodiment 1 by the gravure printing method, and dried. , thereby forming an electrode film (electrode pattern). For the electrode pattern formed using the plate making different from Embodiment 1 in this gravure printing, it carried out similarly to Em...

Embodiment approach 3

[0120] As ceramic green sheets, the same ceramic green sheets as those in Embodiment 1 and ceramic green sheets using acrylic resin as a binder were prepared, and the conductive surface of sample 2 produced in Embodiment 1 was coated on the surface of these green sheets by the gravure printing method. The paste composition is formed and dried to form an electrode film (electrode pattern). A plate making different from Embodiments 1 and 2 is used in this gravure printing. About the formed electrode pattern, it carried out similarly to Embodiment 1, and evaluated the printability and sheet erosion property. The evaluation results are shown in Table 4 below.

[0121] [Table 4]

[0122] Table 4

[0123]

[0124] As shown in Table 4, the conductive paste composition of Sample 2 has both good printability and sheet erosion properties, and it can be confirmed that it is suitable for various plate making and ceramic green sheets using acrylic and butyral resins. Either one is o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com