Modified lignin based carburizing agent and preparation method thereof

A lignin-based and lignin-based technology, which is applied in the field of lignin-based carbon formers and their preparation, can solve the problems of complex post-processing, numerous steps, and reduced lignin utilization efficiency, so as to achieve difficult migration, realize industrialized production, and simplify reformation. The effect of sexual steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of a modified lignin-based carbon forming agent, the preparation method comprising the steps of:

[0027] 1) Add soft lignin (SKL) (about 0.01 mole) into a three-necked flask filled with tetrahydrofuran (THF), and stir to make SKL evenly dispersed;

[0028] 2) Add 0.011 moles of triethylamine and mix well;

[0029] 3) Add 0.01 mole of THF solution of diphenoxyphosphoryl chloride dropwise at room temperature, and finish adding dropwise in 1.0 hr;

[0030] 4) Slowly increase the temperature to 67 o C, heat preservation reaction 8 hr;

[0031] 5) After the reaction, the mixture was rotated to remove part of the solvent, then added to methanol for precipitation, and the precipitate was washed with methanol several times;

[0032] 6) The target product is obtained after drying the obtained precipitate.

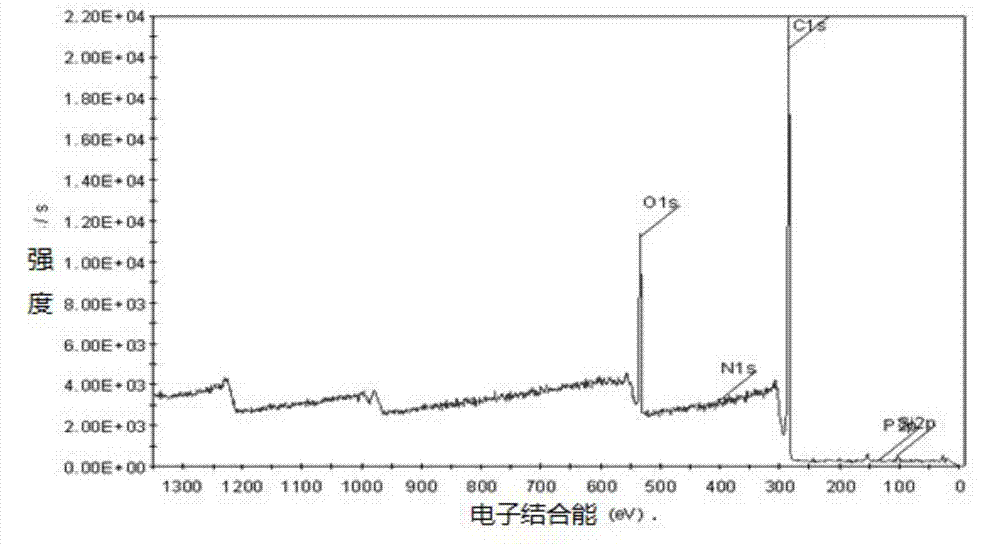

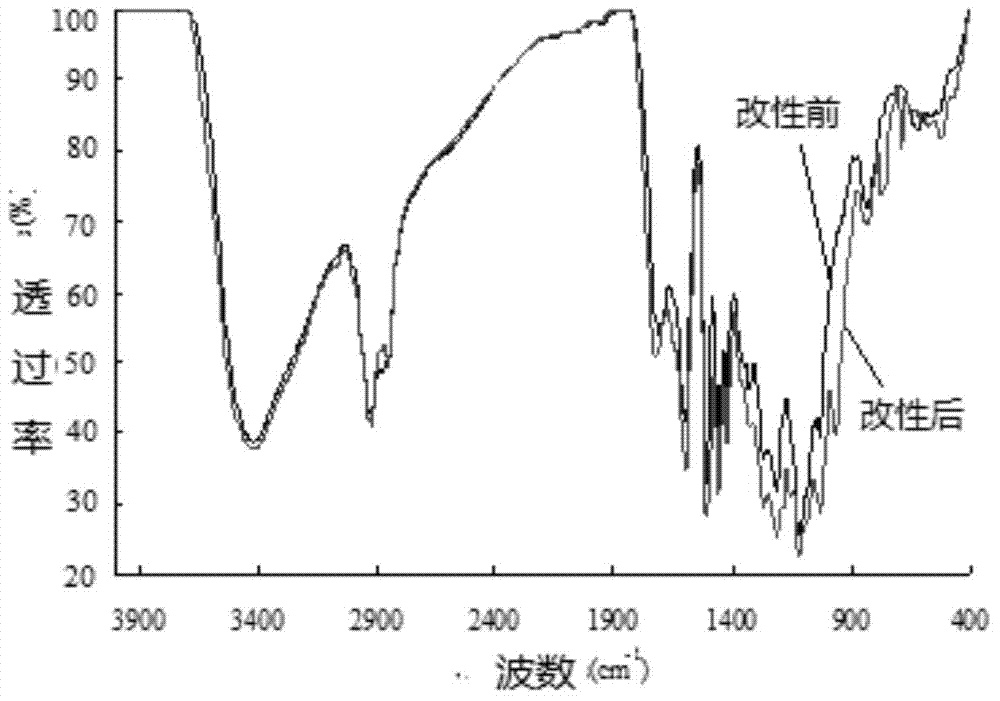

[0033] The infrared spectrogram of gained modified lignin-based carbon forming agent is shown in figure 1 , by comparing with the spectrum befo...

Embodiment 2

[0037] 1) Add alkali lignin (about 0.005 mol) into a three-necked flask filled with tetrahydrofuran (THF), and stir to disperse the alkali lignin evenly;

[0038] 2) Add 0.020 moles of triethylamine and mix well;

[0039] 3) Add 0.015 moles of diphenoxyphosphoryl chloride THF solution dropwise at room temperature, and finish adding dropwise in 1.5 hr;

[0040] 4) Slowly increase the temperature to 67 o C, heat preservation reaction 12 hr;

[0041] 5) After the reaction, the mixture was rotated to remove part of the solvent, then added to methanol for precipitation, and the precipitate was washed with methanol several times;

[0042] 6) The target product is obtained after drying the obtained precipitate.

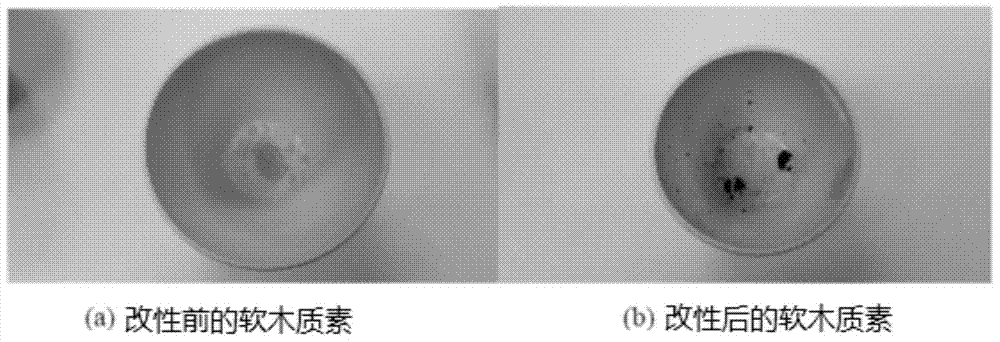

[0043] Figure 4 Muffle furnace 500 before and after alkali lignin modification o In the digital photo of C residual charcoal, it can be clearly seen from the picture that the charring effect of alkali lignin after modification has been significantly improved, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com