Silicon/carbon composite anode material for lithium ion batteries and preparation method thereof

A negative electrode material and carbon composite technology, applied in the direction of battery electrodes, batteries, negative electrodes, etc., can solve the problems of restricting battery cycle performance and rate performance, shortening lithium ion transmission distance, mechanical pulverization, etc., and achieve good lithium ion transmission performance , Ensure electrochemical stability, reduce the possible effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

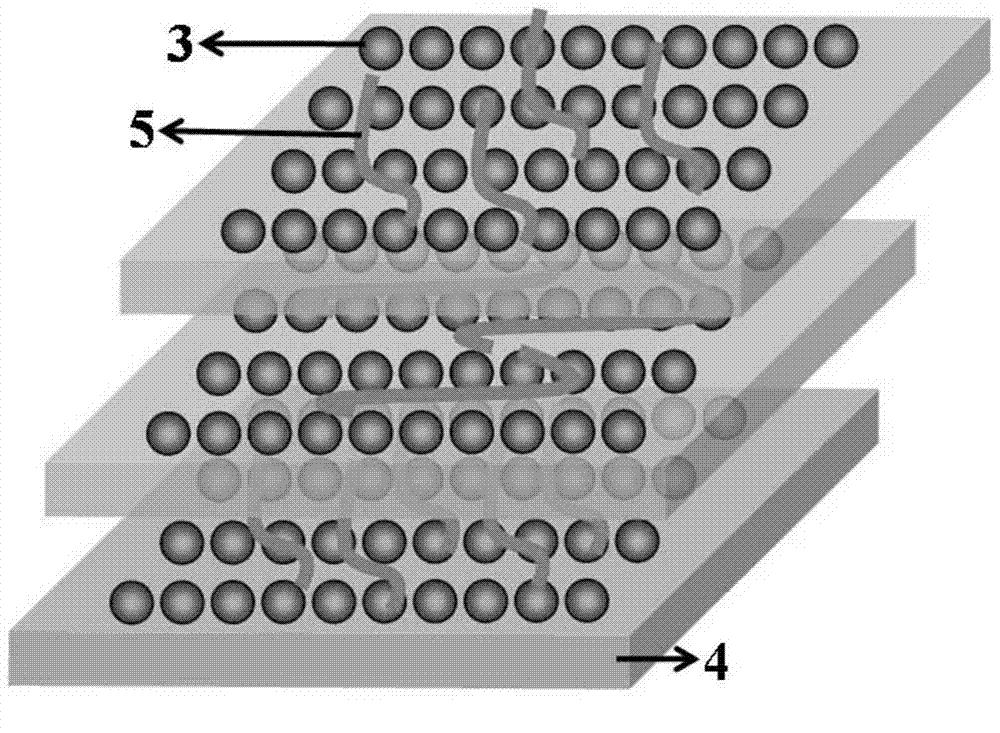

[0047] The preparation process of the silicon / carbon composite structure negative electrode material of the present invention comprises the following specific preparation steps:

[0048] (1) Preparation of carbon-coated silicon-containing materials: take the silicon-containing material SiO with a mass ratio of 0.1 to 4 z 1 and amorphous carbon precursor 2, and 0≤z≤2, the above two materials are dispersed into ethanol, water or a mixed solution of the two through mechanical stirring, wherein the silicon-containing material SiO z It is in the form of powder, and its particle size is less than 3 μm; the above-mentioned dispersion solution is spray-dried or blast-dried; and the product obtained by drying is sintered and carbonized at 180-600 ° C in a protective atmosphere to obtain a carbon-coated Silicon material 3;

[0049] The precursor of amorphous carbon is one or more of glucose, sucrose, starch and phenolic resin, which is mainly used to form a conductive carbon layer on t...

Embodiment 1

[0057] Get 16g of silicon nanoparticles (particle size D50 is 30nm) and 24g of glucose dispersed in 400g of ethanol, mechanically stirred for 0.5h, and then spray-dried to obtain granular powder, the granular powder in a tube vacuum furnace, Argon protection, calcination at 200°C for 0.5h to obtain material A.

[0058] Take 2g of the above-mentioned material A, and disperse it in 2g of liquid vinyl tris(2-methoxyethoxy)silane monomer compound by mechanical stirring, add 10g of ethanol and 0.5g of hydrochloric acid aqueous solution with a pH of 4, and mechanically After stirring for 0.5 h, add 0.1 g of carbon fiber and 8 g of graphite, and mechanically knead for 10 min to obtain paste mixture B.

[0059] Put the above paste mixture B into a vacuum tube furnace, under argon protection, and calcinate at 750°C for 90 minutes to obtain a block composite material C, whose stoichiometric formula can be expressed as 0.083Si0.058AC-0.059SiO 1.5 C 2.1 &0.0118CF-C.

[0060] The above-...

Embodiment 2

[0063] The same process as in Example 1, except that the amount of carbon fiber added was increased from 0.1 g in Example 1 to 0.3 g. The composite materials obtained under this example have a capacity of 768.5mAh / g and 583.7mAh / g before delithiation for the first time, and a Coulombic efficiency of 75.9% for the first time; after 10 cycles, the specific capacity is 629.6mAh / g, and the capacity retention rate is 107.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com