Horizontal type coal briquette drying machine

A dryer and briquettes technology, applied in dryers, drying, drying of solid materials, etc., can solve the problems of high production and maintenance costs, lower drying efficiency, lower briquettes qualification rate, etc., to reduce maintenance and repair frequency, The effect of reducing equipment load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

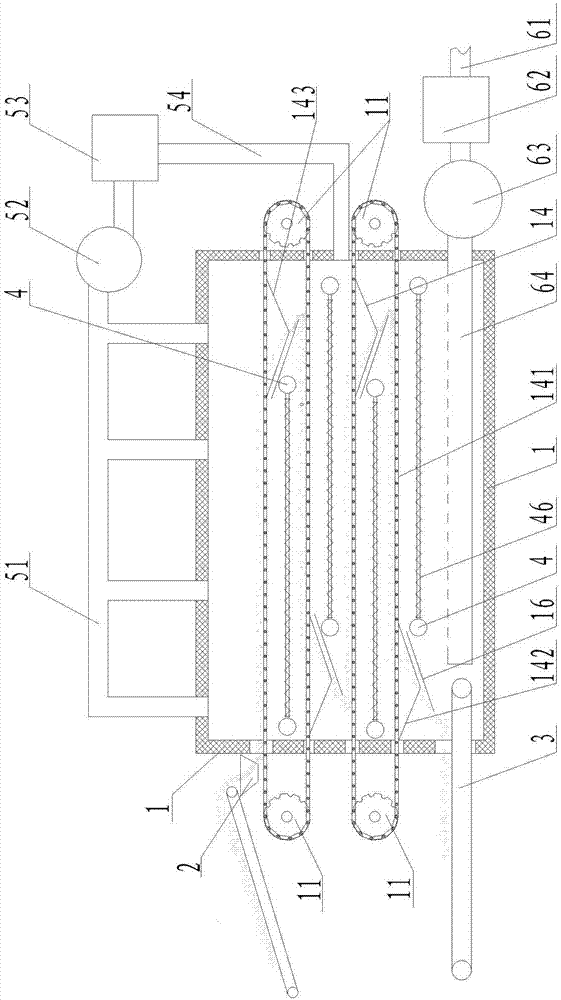

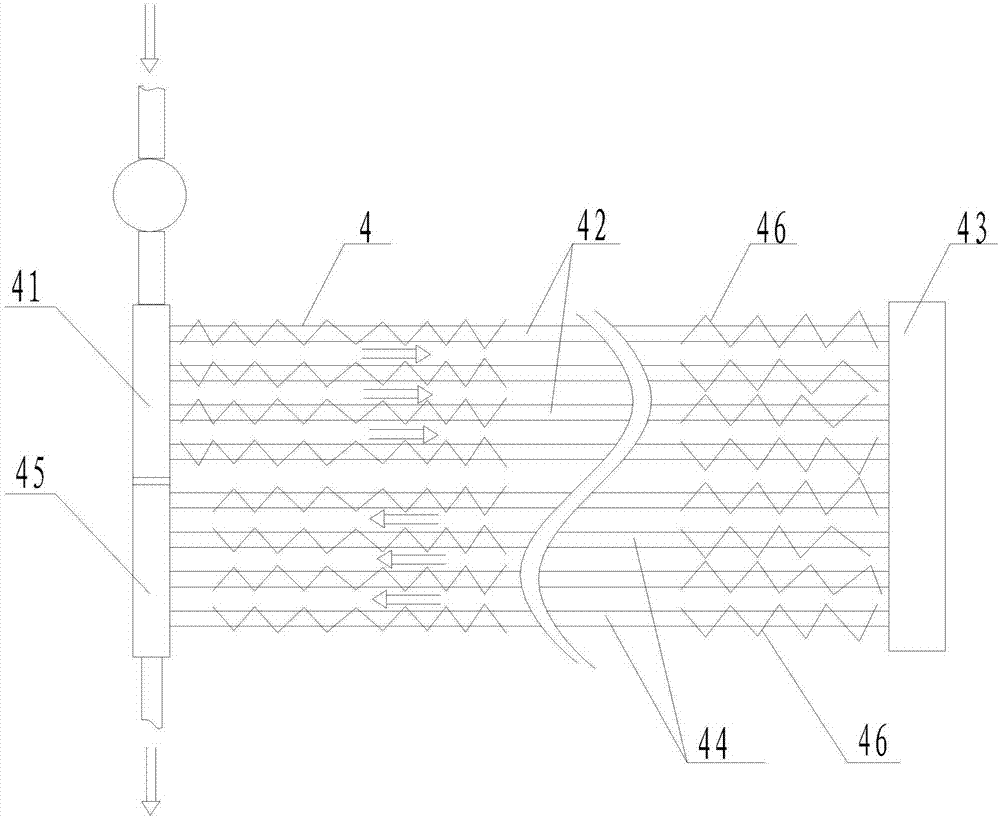

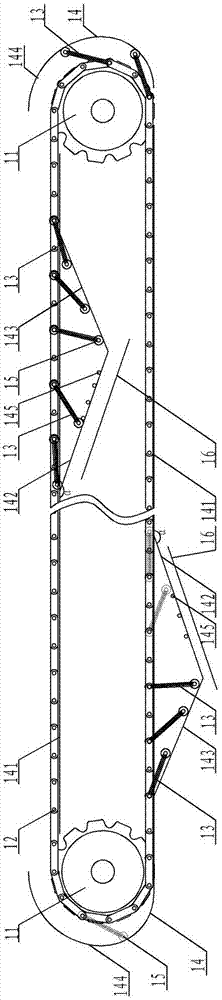

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] as attached Figure 1-6As shown, a horizontal briquette dryer includes a drying chamber 1, a chain plate conveying mechanism arranged in the drying chamber 1, a feed hopper 2 arranged at the top of the drying chamber 1, and a One side of the discharge conveyor belt 3, heating system, wind circulation device and tail gas recovery device; the chain plate conveying mechanism includes a double-drive chain mechanism and its supporting sprocket 11, and one side is positioned on the grid on the chain shaft 12 Plate 13 and the guide rail 14 that guides the movement of the other side of the grid plate 13, the grid plate 13 is a hollow structure, the grid plate 13 is hinged with the chain shaft 12, and the other side of the grid plate 13 passes through The guide wheel 15 is pressed on the guide rail 14, and it is characterized in that: the grid plate 13 is a ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com