Glass welded metal vacuum insulation board with extraction opening and production method thereof

A technology of vacuum insulation panels and air extraction ports, which is applied in building components, thermal insulation, sound insulation, etc., to achieve the effects of reducing weight, reducing material and energy consumption, and making the production process simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be described in detail below with examples and accompanying drawings, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention.

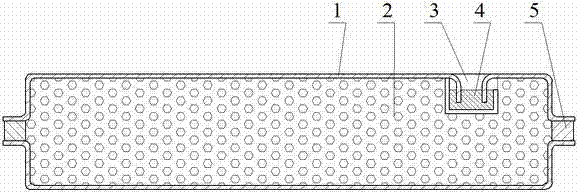

[0031]Referring to the accompanying drawings, the glass-welded metal vacuum insulation panel with an air exhaust port is composed of an outer shell 1, a core material 2 and an air exhaust port 3. The outer shell 1 is composed of a low-carbon steel plate with a thickness of 0.3-1.0mm; the core material 2 is glass fiber, pearlescent sand, perlite, vermiculite, aerogel, etc., the core material 1 is preferably dried, packaged in plastic bags, pre-vacuumized, etc.; Composed of a metal box, low-temperature solder 4 such as tin, zinc, magnesium and low-melting point alloys are placed in the metal box, and the low-temperature solder 4 will automatically seal the air outlet 3 after melting. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com