Magnesium alloy surface modification method

A surface modification, magnesium alloy technology, applied in the direction of metal material coating process, superimposed layer plating, coating, etc., can solve the problems of uncontrollable, fast corrosion, insufficient surface modification, etc., to promote adhesion and growth, improve biological activity, and expand the effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing hydroxyapatite on the surface of a magnesium alloy treated by micro-arc oxidation, the specific steps are as follows:

[0030] (1) Substrate surface pretreatment

[0031] Polish the magnesium alloy sheet with 100-mesh, 300-mesh and 2000-mesh sandpaper in turn until the surface is bright, and then ultrasonically clean it with acetone for 5 minutes to obtain a clean metal surface;

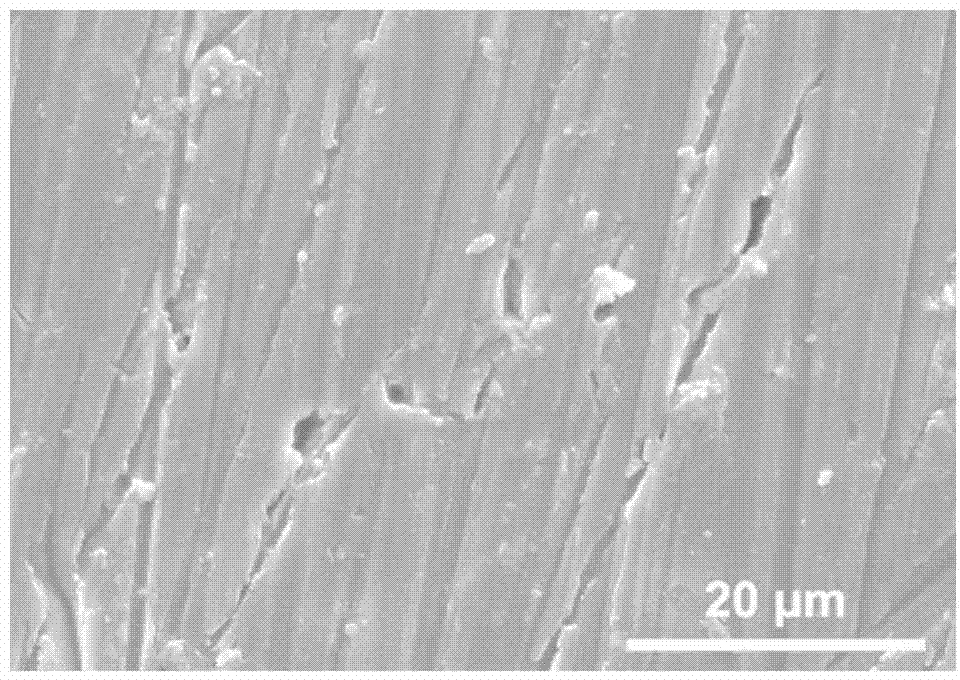

[0032] (2) Micro-arc oxidation

[0033] With 15g / L Na 2 SiO 3 and 3g / L KOH solution as the electrolyte, the magnesium alloy sheet processed in step (1) is the anode, and the graphite is the cathode, the magnesium alloy sheet and the graphite rod are immersed in the electrolyte, and the voltage is 350V, the frequency is 100Hz, and the duty cycle A DC pulse power supply with a ratio of 30% and a distance between Yin and Yang of 4 cm is used to perform plasma anodic oxidation treatment on magnesium alloy, and the treatment time is 10 minutes;

[0034] (3) Deposition of ...

Embodiment 2

[0039] A method for preparing hydroxyapatite on the surface of a magnesium alloy treated by micro-arc oxidation, the specific steps are as follows:

[0040] (1) Substrate surface pretreatment

[0041] With embodiment 1;

[0042] (2) Micro-arc oxidation

[0043] With 5g / L Na 2 SiO 3 And 1g / L KOH solution is the electrolyte, the magnesium alloy sheet after step (1) is the anode, and the graphite is the cathode. The magnesium alloy sheet and the graphite rod are immersed in the electrolyte, and the voltage is 200V, the frequency is 300Hz, and the duty cycle A DC pulse power supply with a ratio of 10% and a distance between Yin and Yang of 3 cm is used to perform plasma anodic oxidation treatment on magnesium alloy, and the treatment time is 20 minutes;

[0044] (3) Deposition of polydopamine

[0045] The magnesium alloy after step (2) is soaked in the dopamine hydrochloride solution of 1mg / mL for 0.5 hour, obtains the magnesium alloy of surface deposition polydopamine film l...

Embodiment 3

[0049] (1) Substrate surface pretreatment

[0050] With embodiment 1;

[0051] (2) Micro-arc oxidation

[0052] With 50g / L Na 2 SiO 3 And 5g / L KOH solution is electrolyte, the magnesium alloy sheet after step (1) is anode, and graphite is cathode, magnesium alloy sheet and graphite rod are immersed in electrolyte, and adopting voltage is 500V, frequency is 500Hz, duty cycle A DC pulse power supply with a ratio of 50% and a distance between Yin and Yang of 6 cm is used to perform plasma anodic oxidation treatment on magnesium alloy, and the treatment time is 30 minutes;

[0053] (3) Deposition of polydopamine

[0054] The magnesium alloy after step (2) is soaked in the dopamine hydrochloride solution of 6mg / mL for 2 hours, obtains the magnesium alloy of surface deposition polydopamine film layer; Described dopamine hydrochloride solution uses 10mM, the Tris buffer solution that pH value is 8.5 preparation;

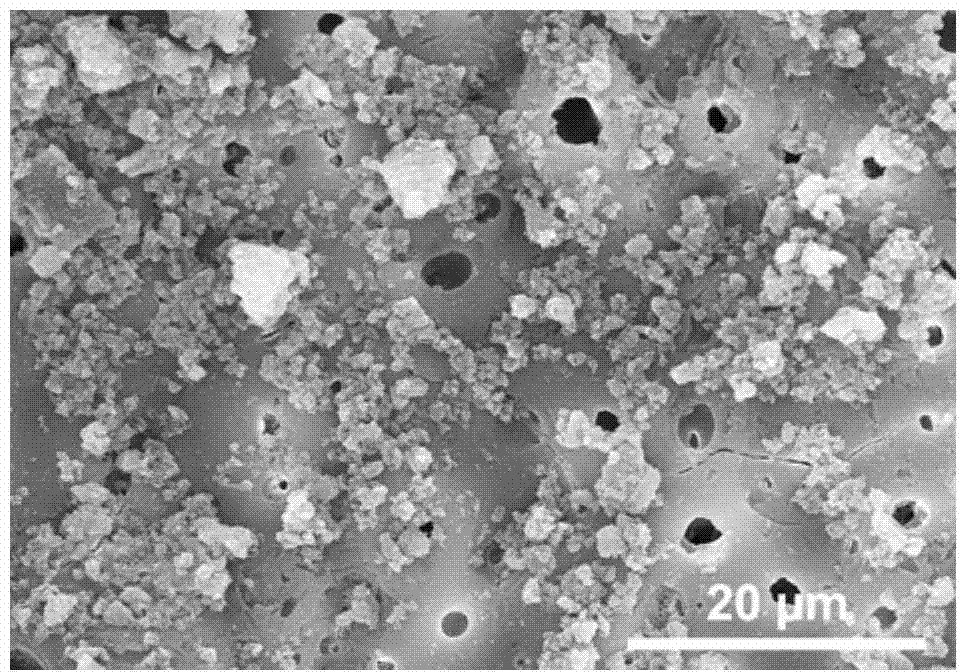

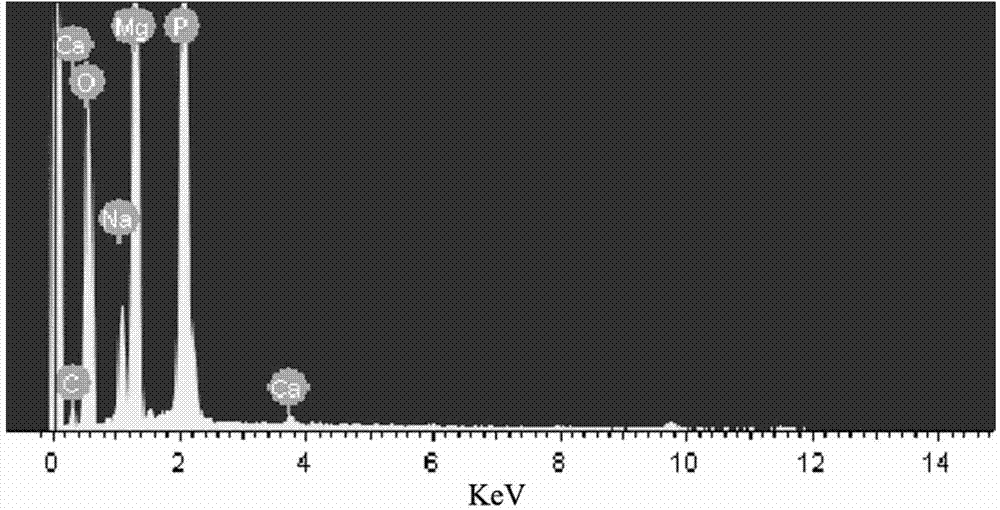

[0055] (4) Deposition of hydroxyapatite

[0056]Soak the magnes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com