Polyethylene eco-friendly flame-retardant foaming plastic and preparation method thereof

A foamed plastic and polyethylene technology, which is applied in the field of polyethylene environmentally friendly flame-retardant foamed plastics and its preparation, can solve the problems of poor tensile strength of materials, excessive flame retardants, waste of production resources, etc., and achieve improved tensile properties , reduce the content of use, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

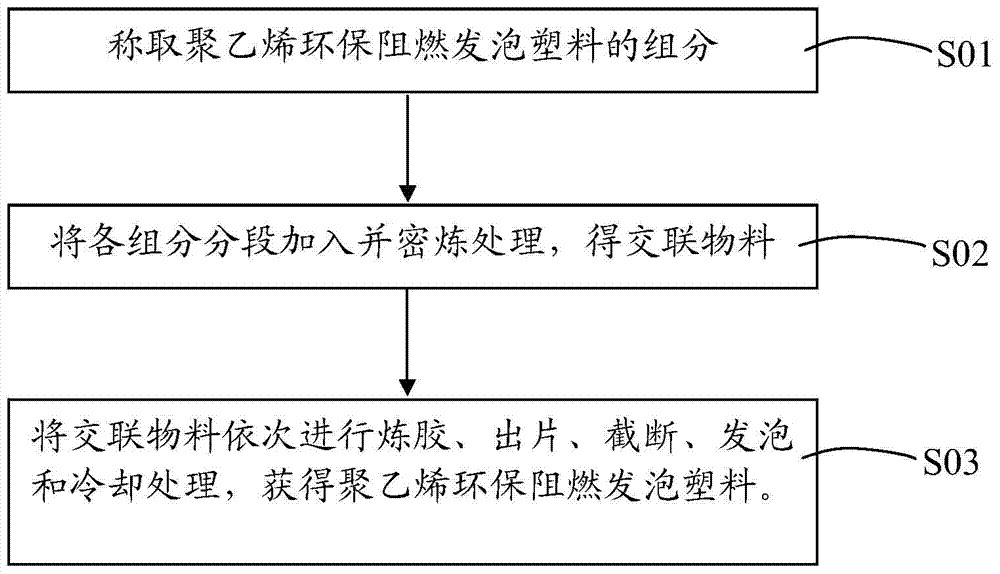

[0031] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned polyethylene environment-friendly flame-retardant foamed plastic, the process flow of which is as follows figure 1 shown. The method includes the following steps:

[0032] S01. Weigh the components of polyethylene environmentally friendly flame-retardant foamed plastic: weigh each component according to the above-mentioned formula of polyethylene environmentally friendly flame-retardant foamed plastic;

[0033] S02. Add each component in stages and banbury for processing to obtain a cross-linked material: After stirring the weighed polyoxymethylene, add high-pressure low-density polyethylene, ultra-high molecular weight polyethylene, chopped basalt fiber, zircon powder and The flame retardant is subjected to one-stage banburying treatment, and then zinc oxide and stearic acid are added for second-stage banburying treatment, and then high-temperature foamin...

Embodiment 1

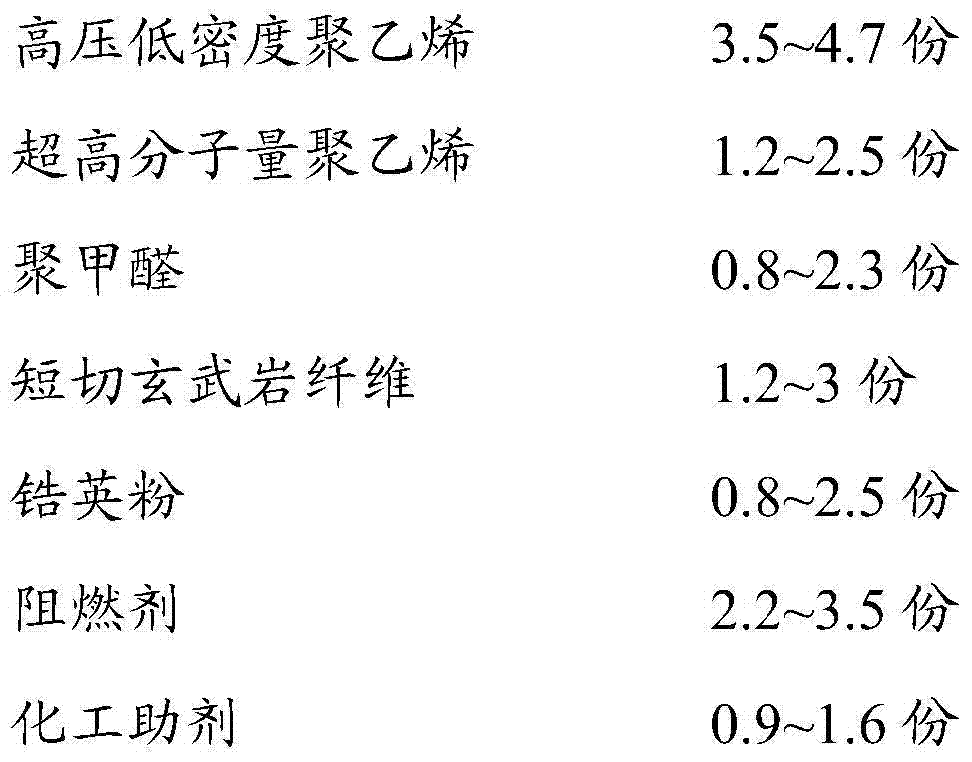

[0043] A polyethylene environment-friendly flame-retardant foamed plastic, comprising the following components by weight:

[0044]

[0045] The preparation method of the polyethylene environment-friendly flame-retardant foamed plastic of above-mentioned embodiment 1 comprises the following steps:

[0046] S11. Weigh each component according to the specific formula of the above-mentioned polyethylene environment-friendly flame-retardant foamed plastic;

[0047] S12. Put the weighed polyoxymethylene into a mixer at a temperature of 180° C. to 230° C. and stir for 1 to 3 minutes to soften it. Then put it into the internal mixer together with the weighed ultra-high molecular weight polyethylene, high-pressure low-density polyethylene, chopped basalt fiber, zircon powder and melamine phosphate; The temperature gauge measures 55°C to 65°C, and the pressure cover and dust cover are covered for banburying. When the temperature rises to about 65°C, add zinc oxide and stearic acid ...

Embodiment 2

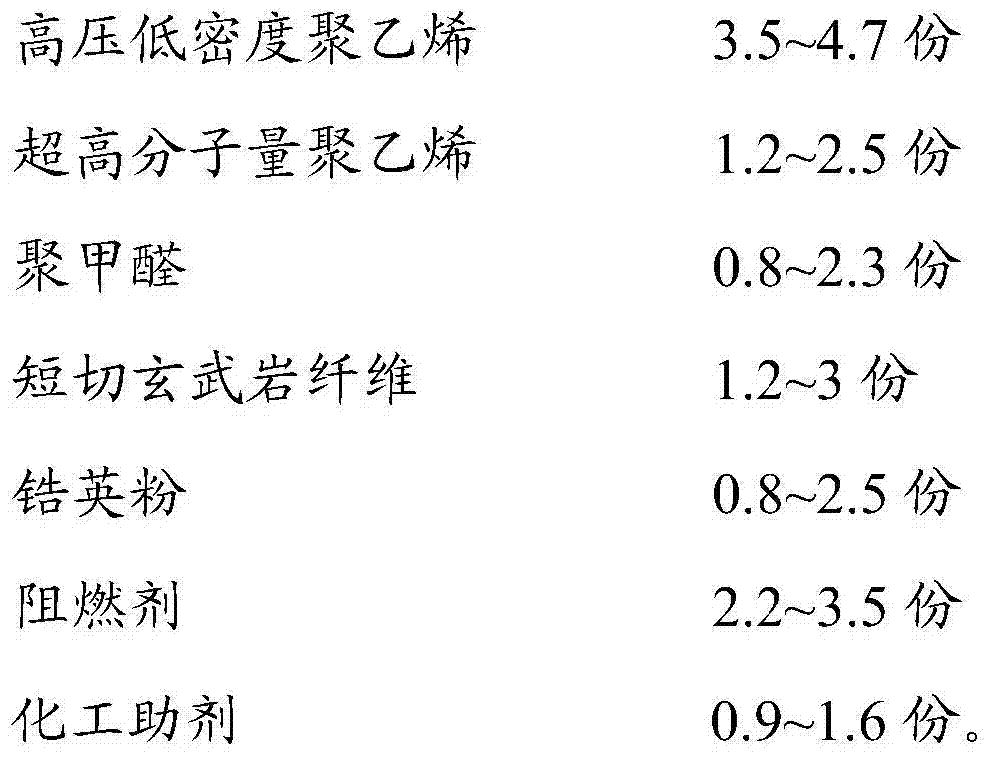

[0050] A polyethylene environment-friendly flame-retardant foamed plastic, comprising the following components by weight:

[0051]

[0052]

[0053] The preparation method of the polyethylene environment-friendly flame-retardant foamed plastic in Example 2 is the same as the preparation method of the above-mentioned Example 1, and will not be described here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com